Abstract

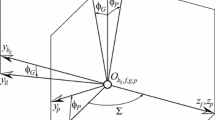

The formation of spiral teeth of bevel gears is one of the most complicated areas for simulation, synthesis and analysis of processes in the gear technology in general. The practical technique of production is also complex and specific with regard to equipment, tools and personnel. The main purpose of this manuscript is to present an alternative, simpler and cheaper method of spiral teeth generation with respect to production preparation. The paper gives reasons for the possibility of generating the spiral teeth of bevel gearwheels by two helical surfaces with the constant pitch. The idea of generation comes from the evident exterior similarity of gearwheels of non-orthogonal spiroid gears and bevel gears. The paper presents mathematical models of operating and machine-tool surface generating gearing schemes. The following stages of gearing synthesis are introduced: synthesis of the machine-tool meshing of the pinion; synthesis of the bevel gear scheme; synthesis of the machine-tool meshing of the gearwheel in accordance with local conditions stated at points that are arbitrarily chosen on opposite tooth flanks; and analysis of contact localization. Due to similarity of the problem statement, there exists a big enough number of parameters to control the tooth geometry. The paper presents the corresponding algorithm for the choice of machine-tool setting parameters, methods of calculation of flanks and transient tooth surfaces, and evaluation of the level of contact localization. Calculation examples, conclusions on their results and recommendations on the choice of parameters are given. In particular, the main features of the method are specified: narrowness of the area of possible solutions; acceptability and even request of a certain undercut of concave tooth flanks; the tooth spiral angle that is greater than that of traditional bevel gears; preferability of application of the proposed method for gear ratios 1…1.4. The obtained results give prospects of development of the cost-efficient technique of tooth machining of spiral bevel gears within low series production.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Babichev, D.T.: Development of kinematic method of theory of gearing to determine areas of tooth flanks produced by jogs of generating solids. In: Honor of Professor Faydor, L., Litvin, V., Goldfarb, N., Barmina (eds.) Chapter in Theory and Practice of Gearing and Transmissions, vol. 34, pp. 159–188. Springer, Berlin (2016)

Goldfarb, V.I., Ezerskaya, S.V.: To the choice of the value of the helical parameter in the orthogonal spiroid gear with the cylindrical worm. J. Izvestiya Vuzov, Mashinostroyeniye 2, 184–186 (1975). (in Russian)

Goldfarb, V.I., Russkikh, A.G.: Computer-aided synthesis of gear structure at arbitrary arrangement of axes. In: Proceedings of 6th International Conference on the Theory of Machines and Mechanisms, pp. 65–70. Czechoslovakia (in Russian) (1992)

Goldfarb, V.I., Trubachev, E.S.: System of hob unification for cutting the gearwheels of worm-type gears. In: Proceedings of ASME 2007 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Las-Vegas, USA (2007)

Korostelev, L.V., Baltadzhi, S.A., Lagutin, S.A.: Conjugated lines of meshing of general-type worm gears. J. Mashinovedeniye 5, 49–56 (1978). (in Russian)

Lagutin, S.A.: Local synthesis of general type worm gearing and its applications. In: Proceedings of 4th World Congress on Gearing and Power Transmissions, vol.1, pp. 501–506. Paris (1999)

Litvin, F.L.: Theory of Gearing. Nauka (in Russian), Moscow (1968)

Lopato, G.A., Kabatov, N.F., Segal, M.G.: Bevel and Hypoid Gears with Circular Teeth. Mashinostroenie (in Russian), Leningrad (1977)

Segal, M.G.: To Determination of Boundaries of the Contact Pattern of Bevel and Hypoid Gears, vol. 4, pp. 61–68. Moscow, Mashinovedeniye (in Russian) (1972)

Sheveleva, G.I.: Theory of Generation and Contact of Moving Solids. Moscow, Stankin (in Russian) (1999)

Syzrantsev, V., Kotlikova, V.: Mathematical and program provision of design of bevel gearing with small shaft angle. In: Proceedings of International Conference on Gearing, Transmissions and Mechanical Systems, pp. 13–18. Nottingham (2000)

Trubachev, E., Savelyeva, T., Pushkareva T.: Practice of design and production of worm gears with localized contact. In: Goldfarb, V., Trubachev, E., Barmina, N. (eds.) Chapter in Advanced Gear Engineering. Mechanisms and Machine Science, vol. 51, pp. 327–344. Springer, Berlin (2018)

Trubachev, E.S.: Vector field of normal vectors and its application to investigation of geometry of spiroid gearing with the helicoid worm. In: Chapter in Problems of Design of Mechanical Engineering and Information Technology Products, pp. 3–14. Izhevsk, 3–14 (in Russian) (1999)

Trubachev, E.S.: Method of parameters calculation for the machine-tool gearing with the helicoid generating surface. In: Chapter in Advanced Information Techniques. Problems of Investigation, Design and Production of Gears, pp. 163–169. Izhevsk (in Russian) (2001)

Trubachev, E.S.: New Possibilities of Gear Cutting by Rolling Cutter Heads. In this book (2020)

Trubachev, E.S., Beresneva, A.V., Monakov, A.V.: Calculation of point coordinates of the surface generated by a helicoid. In: Proceedings of the Scientific Seminar of the Educational Scientific Center of Gears and Gearbox Engineering, Problems of Improving Gears, pp. 124–134. Izhevsk-Moscow (in Russian) (2000)

Trubachev, E.S., Oreshin, A.V.: CAD system for spiroid gears. J. Inform. Math. 1(3), 159–165 (2003). M.: Publishers of physical mathematical literature (in Russian)

Trubachev, E.S., Savelyeva, T.V.: Optimization task at computer-aided design of spiroid gears based on single-thread unified hobs. J. Inform. Math. 1(5), 121–130 (2005). M.: Publishers of physical mathematical literature (in Russian)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Trubachev, E.S. (2020). On Possibility of Cutting Bevel Gearwheels by Hobs. In: Goldfarb, V., Trubachev, E., Barmina, N. (eds) New Approaches to Gear Design and Production. Mechanisms and Machine Science, vol 81. Springer, Cham. https://doi.org/10.1007/978-3-030-34945-5_11

Download citation

DOI: https://doi.org/10.1007/978-3-030-34945-5_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-34944-8

Online ISBN: 978-3-030-34945-5

eBook Packages: EngineeringEngineering (R0)