Abstract

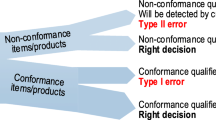

The article presents the results in the field of assessment and improvement of the effectiveness of visual inspection of products - airbag modules, manufactured by a company from the automotive industry (Tier 1 supplier). The research was carried out using the Kappa index and auxiliary indicators proposed by the automotive industry for the assessment of the inspection system consisting of 3 controllers involved in the inspection of the above-mentioned products. The results showed numerous interesting interdependencies in the inspectors’ classifying the specially selected sample of products into two qualitative categories (OK, NOK). The findings included, among other things, poor or average compliance of the controllers’ decisions with the expert’s decision, an unacceptably high share of the type II errors consisting in the acceptance of a non-conforming product - this applied to all controllers, and a poor result of the entire control system (3 controllers verified in total). Furthermore, the conducted research allowed to develop a ranking of controllers. The obtained research output led to actions intended to improve the alternative product control system including the trainings for all controllers, the modification of the visual assessment standard and implementation of the Andon system.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Hamrol, A.: Strategies and practices of efficient operation. Lean Six Sigma and other (in Polish), (PWN), Warsaw (2015)

Czerska, J.: Improving the value stream (in Polish), (Difin), Warsaw (2009)

Borkowski, S., Knop, K.: Challenges faced in modern quality inspection. Manag. Prod. Eng. Rev. 7(3), 11–22 (2016)

Webber, L., Wallace, M.: Quality Control for Dummies. Wiley, Hoboken (2007)

Ulewicz, R.: Practical application of quality tools in the cast iron foundry. Manuf. Technol. 14(1), 104–111 (2014)

Czyżewski, B.: Internal quality control in a production company (in Polish), (Wielkopolski Quality Club FSNT NOT), Poznan (2007)

Rewilak, J.: Do you trust visual inspection? (in Polish), TQM Soft. http://szkolenia.tqmsoftcom/inspekcja. Accessed 20 Mar 2013

Kujawińska, A., Vogt, K.: Human factors in visual quality control. Manag. Prod. Eng. Rev. 6(2), 25–31 (2015)

Schultz, D.: Psychology and the challenges of today’s work (in Polish), (PWN), Warsaw (2012)

See, J.E.: Visual inspection reliability for precision manufactured parts. Hum. Factors 57(8), 1427–1442 (2015)

Charles, R., Fletcher, S.R., Tailor, M.: Search patterns in human visual inspection. In: Contemporary Ergonomics and Human Factors, Proceedings of the International Conference on Ergonomics & Human Factors, 13–16 April 2015

Johnson, L.: Can You Improve Your Visual Inspection Process? https://www.minitab.com/uploadedFiles/Content/News/Published_Articles/inspection_process_improvement_breakthrough.pdf. Accessed 05 Dec 2018

Hamrol, A., Kowalik, D., Kujawińska, A.: Impact of selected work condition factors on quality of manual assembly process. Hum. Factors Ergon. Manuf. Serv. Ind. 21(2), 156–163 (2011)

Vogt, K., Kujawińska, A.: Analysis of the effect of the type of nonconformity on the effectiveness of visual inspection (in Polish). In: Knosala, R. (ed.) Innovation in Management and Production Engineering, vol. 2, pp. 470–480 (2014)

Kujawinska, A., Vogt, K., Diering, M., Rogalewicz, M., Waigaonkar, S.D.: Organization of visual inspection and its impact on the effectiveness of inspection, In: Hamrol, A., Ciszak, O., Legutko, S., Jurczyk, M. (eds.) Advances in Manufacturing. LNME, pp. 899–909 (2018)

Purswell, J.L., Hoag, L.L.: Strategies for improving visual inspection performance. In: Proceedings of the Human Factors and Ergonomics Society Annual Meeting, vol. 18, no. 4, pp. 397–403 (1974)

See, J.E., Drury, C.G., Speed, A., Williams, A., Khalandi, N.: The role of visual inspection in the 21st century. In: Proceedings of the Human Factors and Ergonomics Society, pp. 262–266 (2017)

Schoonahd, J.W., Gould, J.D., Miller, L.A.: Studies of visual inspection. Ergonomics 16(1973–4), 365–379 (2007)

Kavuri, S.H.: Size Effects in human visual inspection for micro/meso scale parts, mechanical (and materials) engineering. Dissertations, Theses, and Student Research, p. 81 (2015)

Thapa, V.B., Gramopadhye, A.K., Melloy, B., Grimes, L.: Evaluation of different training strategies to improve decision making performance in inspection. Int. J. Hum. Factors Manuf. 6(3), 243–261 (1996)

Lee, J., Ko, K.W., Lee, S.: Visual inspection system of the defect of collets for wafer handling process. Int. J. Control Autom. 9, 129–138 (2016)

Drury, C.G., Watson, J.: Good practices in visual inspection, Human factors in aviation maintenance-phase nine, progress report, FAA/Human Factors in Aviation Maintenance (2002). https://www.faa.gov/data_research/research/med_humanfacs/oamtechreports/1990s/media/AM91-16.pdf. Accessed 29 Oct 2018

Knop, K., Ingaldi, M., Śmiłek-Starczynowska, M.: Reduction of errors of the conformity Assessment during the visual inspection of electrical devices. In: Advances in Manufacturing, LNME, pp. 857–867. Springer, Heidelberg (2018)

Reinfus, R.: MBO - a simple and effective technique for managing your company (in Polish). Warsaw (2011). (Helion)

Knop, K., Borkowski, S.: The estimation of alternative control efficiency with the use of the Cohen’s Kappa coefficient. Manag. Prod. Eng. Rev. 2(3), 19–27 (2011)

Measurement System Analysis (MSA), Reference Manual, 4th Edn. AIAG Group (2010)

Diering, M., Kujawińska, A.: MSA-Measurement System Analysis. Guide to procedures (in Polish), Poznan (2012). (AR Comprint)

Gramopadhye, A.K., Drury, C.G., Sharit, J.: Feedback strategies for visual search in airframe structural inspection. Int. J. Ind. Ergon. 19(5), 333–344 (1997)

Boucher-Genesse, A.: The Human Brain VS the Digital Brain - A Case for Visual Inspections (2016). https://blog.robotiq.com/human-brain-vs-digital-brain-what-is-so-different-case-study-for-a-visual-inspection. Accessed 30 Nov 2018

Smith, C.J., Adendorff, K.: Advantages and limitations of an automated visual inspection system. South Afr. J. Ind. Eng. 5(1), 27–36 (1991)

Stoller, J.: The Lean CEO: Leading the Way to World-Class Excellence: Leading the Way to World-Class Excellence. McGraw-Hill Education, New York (2015)

Bożek, M., Rogalewicz, M.: The ineffectiveness of the final control the reason of the low efficiency of the production process (in Polish), Engineering of Machines (in Polish), R. 18, z. 1, pp. 84–96 (2013)

See, J.E.: Visual inspection: a review of the literature (Report SAND2012-8590). Sandia National Laboratories, Albuquerque (2012)

Clemons, A.J.: Training methods for visual inspection tasks. Iowa State University Capstones, Graduate Theses and Dissertations, 13005 (2013)

Ulewicz, R.: Outsourcing quality control in the automotive industry. In: MATEC Web of Conference, vol. 183, p. 03001 (2018)

Klaput, P., Vykydal, D.: Effect of the number of non-conforming samples on the Kappa indicator values. In: MATEC Web of Conference, vol. 183, p. 03014 (2018)

Diering, M., Dyczkowski, K., Hamrol, A.: Estimating the level of conformity of assessments in visual inspection - problems in determining the Kappa coefficients (in Polish), Innovations in management and production engineering (in Polish), pp. 257–268. Publishing House of the Polish Society for Production Management (2015)

Jarosz-Nowak, J.: Models of assessing the extent of agreement between raters using kappa coefficients (in Polish). Appl. Math. (in Polish) 8, 126–154 (2007)

Wongpakaran, N., Wongpakaran, T., Wedding, D., Gwet, K.L.: A comparison of Cohen’s Kappa and Gwet’s AC1 when calculating inter-rater reliability coefficients: a study conducted with personality disorder samples. BMC Med. Res. Methodol. 13(1), 61 (2013)

Starzyńska, B., Szajkowska, K., Diering, M., Rocha, A., Reis, L.P.: A study of raters agreement in quality inspection with the participation of hearing disabled employees. Advances in Manufacturing. LNME, pp. 881–888. Springer, Heidelberg (2018)

Anttila, J., Jussila, K.: Organizational learning in developing the integrated quality management. Prod. Eng. Arch. 18, 3–13 (2018)

Grabowska, M., Takala, J.: Assessment of quality management system maturity. In: Advances in Manufacturing. LNME, pp. 889–898. Springer, Heidelberg (2018)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Knop, K., Olejarz, E., Ulewicz, R. (2019). Evaluating and Improving the Effectiveness of Visual Inspection of Products from the Automotive Industry. In: Hamrol, A., Grabowska, M., Maletic, D., Woll, R. (eds) Advances in Manufacturing II. MANUFACTURING 2019. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-17269-5_17

Download citation

DOI: https://doi.org/10.1007/978-3-030-17269-5_17

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-17268-8

Online ISBN: 978-3-030-17269-5

eBook Packages: EngineeringEngineering (R0)