Abstract

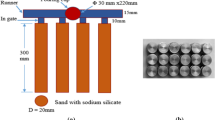

In recent years, CrN coating has been identified as one of the most promising protective layers on surfaces of tools and dies due to its excellent mechanical properties, corrosion resistance, and surface hardness. This study presents the predicting of chromium nitride (CrN) coating surface hardness on AL7075-T6 using fuzzy logic technique. First, Al7075-T6 was coated with CrN at different parameter conditions, after which the surfaces hardness of the CrN-coated specimens was measured using a micro hardness machine. Next, a fuzzy logic model was established to predict the surface hardness of CrN coating on AL7075-T6 with respect to changes in input process parameters, DC power, temperature, and nitrogen flow rate based on the trained data obtained from the micro hardness test. Three membership functions were allocated in connection with each model input. Finally, five new experimental tests were carried out to verify the predicted results achieved via the fuzzy logic model. The results indicate an agreement between the fuzzy model and experimental results with 94.664% accuracy.

Similar content being viewed by others

References

Lugscheider, E., Krämer, G., Barimani, C., and Zimmermann, H., “PVD coatings on aluminium substrates,” Surface and Coatings Technology, Vol. 74–75, Part 1, pp. 497–502, 1995.

Majzoobi, G. H., Nemati, J., Novin Rooz, A. J., and Farrahi, G. H., “Modification of fretting fatigue behavior of AL7075-T6 alloy by the application of titanium coating using IBED technique and shot peening,” Tribology International, Vol. 42, No. 1, pp. 121–129, 2009.

Zhang, X. H., Liu, D. X., Tan, H. B., and Wang, X. F., “Effect of TiN/Ti composite coating and shot peening on fretting fatigue behavior of TC17 alloy at 350 °C,” Surface and Coatings Technology, Vol. 203, No. 16, pp. 2315–2321, 2009.

Cristóbal, A. B., Conde, A., Housden, J., Tate, T. J., Rodríguez, R., Montala, F., and de Damborenea, J., “Electrochemical stripping of hard ceramic chromium nitride coatings,” Thin Solid Films, Vol. 484, No. 1–2, pp. 238–244, 2005.

Sortmann, S., Savan, A., Gerbig, Y., and Haefke, H., “In-process structuring of CrN coatings, and its influence on friction in dry and lubricated sliding,” Wear, Vol. 254, No. 11, pp. 1099–1105, 2003.

Conde, A., Cristóbal, A. B., Fuentes, G., Tate, T., and de Damborenea, J., “Surface analysis of electrochemically stripped CrN coatings,” Surface and Coatings Technology, Vol. 201, No. 6, pp. 3588–3595, 2006.

Leung, R. W. K., Lau, H. C. W., and Kwong, C. K., “An expert system to support the optimization of ion plating process: an OLAPbased fuzzy-cum-GA approach,” Expert Systems with Applications, Vol. 25, No. 3, pp. 313–330, 2003.

Oktem, H., Erzurumlu, T., and Erzincanli, F., “Prediction of minimum surface roughness in end milling mold parts using neural network and genetic algorithm,” Materials & Design, Vol. 27, No. 9, pp. 735–744, 2006.

Latha, B. and Senthilkumar, V. S., “Modeling and Analysis of Surface Roughness Parameters in Drilling GFRP Composites Using Fuzzy Logic,” Materials and Manufacturing Processes, Vol. 25, No. 8, pp. 817–827, 2010.

Balazinski, M. and Jemielnaik, K., “Tool condition monitoring using fuzzy decision support system. In: V CIRP,” International Conference on Monitoring and Automatic Supervision in Manufacturing, pp. 115–121, 1998.

Arghavani, J., Derenne, M., and Marchand, L., “Fuzzy Logic Application in Gasket Selection and Sealing Performance,” The International Journal of Advanced Manufacturing Technology, Vol. 18, No. 1, pp. 67–78, 2001.

Jiao, Y., Lei, S., Pei, Z. J., and Lee, E. S., “Fuzzy adaptive networks in machining process modeling: surface roughness prediction for turning operations,” International Journal of Machine Tools and Manufacture, Vol. 44, No. 15, pp. 1643–1651, 2004.

Palanikumar, K., Karunamoorthy, L., Karthikeyan, R., and Latha, B., “Optimization of machining parameters in turning GFRP composites using a carbide (K10) tool based on the taguchi method with fuzzy logics,” Metals and Materials International, Vol. 12, No. 6, pp. 483–491, 2006.

Latha, B. and Senthilkumar, V. S., “Fuzzy rule based modeling of drilling parameters for delamination in drilling GFRP composites,” Journal of Reinforced Plastics and Composites, Vol. 28, No. 8, pp. 951–964, 2009.

Chen, J. C. and Savage, M., “A Fuzzy-Net-Based Multilevel In-Process Surface Roughness Recognition System in Milling Operations,” The International Journal of Advanced Manufacturing Technology, Vol. 17, No. 9, pp. 670–676, 2001.

Nandi, A. K. and Pratihar, D. K., “Design of a genetic-fuzzy system to predict surface finish and power requirement in grinding,” Fuzzy Sets and Systems, Vol. 148, No. 3, pp. 487–504, 2004.

Biglari, F. R. and Fang, X. D., “Real-time fuzzy logic control for maximising the tool life of small-diameter drills,” Fuzzy Sets and Systems, Vol. 72, No. 1, pp. 91–101, 1995.

Chandrasekaran, M., Muralidhar, M., Krishna, C. M., and Dixit, U. S., “Application of soft computing techniques in machining performance prediction and optimization: a literature review,” The International Journal of Advanced Manufacturing Technology, Vol. 46, No. 5–8, pp. 445–464, 2010.

Mishra, B., Moore, J. J., Lin, J. L., and Sproul, W. D., “Advances in thin film technology through the application of modulated pulse power sputtering,” Materials Science Forum, Vol. 638–642, pp. 208–213, 2010.

Zalnezhad, E., Sarhan, A. D., and Hamdi, M., “Optimizing the PVD TiN thin film coating’s parameters on aerospace AL7075-T6 alloy for higher coating hardness and adhesion with better tribological properties of the coating surface,” The International Journal of Advanced Manufacturing Technology, Vol. 64, No. 1–4, pp. 281–290, 2013.

Sresomroeng, B., Premanond, V., Kaewtatip, P., Khantachawana, A., Kurosawa, A., and Koga, N., “Performance of CrN radical nitrided tools on deep drawing of advanced high strength steel,” Surface and Coatings Technology, Vol. 205, No. 17–18, pp. 4198–4204, 2011.

Cai, F., Huang, X., Yang, Q., Wei, R., and Nagy, D., “Microstructure and tribological properties of CrN and CrSiCN coatings,” Surface and Coatings Technology, Vol. 205, No. 1, pp. 182–188, 2010.

Lin, J., Moore, J. J., Sproul, W. D., Mishra, B., Wu, Z., and Wang, J., “The structure and properties of chromium nitride coatings deposited using dc, pulsed dc and modulated pulse power magnetron sputtering,” Surface and Coatings Technology, Vol. 204, No. 14, pp. 2230–2239, 2010.

Zalnezhad, E., Sarhan, A., and Hamdi, M., “Prediction of TiN coating adhesion strength on aerospace AL7075-T6 alloy using fuzzy rule based system,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 8, pp. 1453–1459, 2012.

Zalnezhad, E., Sarhan, A. A. D., and Hamdi, M., “Investigating the fretting fatigue life of thin film titanium nitride coated aerospace Al7075-T6 alloy,” Materials Science and Engineering: A, Vol. 559, pp. 436–446, 2013.

Sarhan, A. A. D., Zalnezhad, E., and Hamdi, M., “The influence of higher surface hardness on fretting fatigue life of hard anodized aerospace AL7075-T6 alloy,” Materials Science and Engineering: A, Vol. 560, pp. 377–387, 2013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zalnezhad, E., Sarhan, A.A.D.M. & Hamdi, M. Surface hardness prediction of CrN thin film coating on AL7075-T6 alloy using fuzzy logic system. Int. J. Precis. Eng. Manuf. 14, 467–473 (2013). https://doi.org/10.1007/s12541-013-0063-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-013-0063-5