Abstract

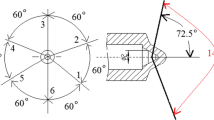

In this study, the effects of two piezo injectors operated by different mechanisms on multi-injection and Compression ignition (CI) combustion were investigated. High-pressure injectors for CI engines are divided into two categories according to the actuator: Solenoid and piezo injectors. It is commonly known that both injectors have a hydraulic circuit for fuel injection; thus, the performance of the injector is highly dependent on not only hydraulic characteristics such as volume of internal chambers and nozzle geometry, but also the actuation mechanism. Specially, the direct needle-Driven piezo injector (DPI) is introduced in this study and compared with the indirectacting Piezo injector (PI) to investigate the injection characteristics and influences on CI combustion performance by using spray visualization, injection rate measurement, and single cylinder diesel engine experiments, as well as numerical simulation for injection rate modeling of DPI. In the spray visualization experiment, a high-speed camera was used to examine spray tip penetration length and spray speed with respect to each injector. Also, in order to investigate injection rate information, which is a significantly dominant factor in combustion characteristics, the Bosch-tube method was adapted under the condition of a back pressure of 4.5 MPa, corresponding to engine motoring pressure. Also, a single-cylinder CRDi (Common-rail direct-injection) engine experiment was carried out to determine the effects of different piezo-acting mechanisms on two-stage fuel injection and CI combustion. From the key results obtained by this study, the direct needle-driven piezo injector has a faster SOI (Start of injection) and EOI (End of injection). In addition, the overall shape of the injection rate of DPI was narrow and the injection had a higher spray speed than that of PI. Also, DPI has a higher heat release rate and peak pressure, as verified by the engine experiment. In particular, it was found that DPI showed the possibility of combustion improvement when applying a pilot injection strategy.

Similar content being viewed by others

References

B. Daham et al., Comparison of real world emissions in urban driving for Euro 1-4 vehicles using a PEMS, SAE Technical Paper 2009-01-0941 (2009).

J. Waldner, J. Wise, C. Crawford and Z. Dong, Development and testing of an advanced extended range electric vehicle, SAE Technical Paper 2011-01-0913 (2011).

A. Joshi, H. Ezzat, N. Bucknor and M. Verbrugge, Optimizing battery sizing and vehicle lightweighting for an extended range electric vehicle, SAE Technical Paper 2011-01-1078 (2011).

H. Nordgren, A. Hultqvist and B. Johansson, Start of injection strategies for HCCI-combustion, SAE Technical Paper 2004-01-2990 (2004).

T. Omori, A. Tanaka, K. Yamada and S. Bunne, Biodiesel deposit formation mechanism and improvement of fuel injection equipment (FIE), SAE Technical Paper 2011-01-1935 (2011).

S. Matsumoto et al., 4th generation diesel common rail system: Realizing ideal structure function for diesel engine, SAE Technical Paper 2013-01-1590 (2013).

N. Milovanovic and S. Hamalian, The fuel consumption and NOx emission optimisation for future diesel passenger cars, SAE Technical Paper, SAE 2016-01-0916 (2016).

L. Postrioti, C. Grimaldi, M. Ceccobello and R. Di Gioia, Diesel common rail injection system behavior with different fuels, SAE Technical Paper 2004-01-0029 (2004).

K. Matsuura, O. Suzuki and A. Kato, In-cylinder optical investigation of combustion behavior on a fast injection rate diesel common rail injector, SAE Int. J. Fuels Lubr., 5 (1) (2012) 88–97.

G. Mohammad and A. R. Noorpoor, NOx reduction in diesel engines using rate shaping and pilot injection, Int. J. of Automotive Technology and Management (2007) 17–31.

R. Payri, F. Salvador, J. Gimeno and G. Bracho, Understanding diesel injection characteristics in winter conditions, SAE Technical Paper 2009-01-0836 (2009).

C. Fettes and A. Leipertz, Potentials of a Piezo-driven passenger car common rail system to meet future emission legislations -An evaluation by means of in-cylinder analysis of injection and combustion, SAE Technical Paper 2001-01-3499 (2001).

G. Dober et al., The impact of injection strategies on emissions reduction and power output of future diesel engines, SAE Technical Paper 2008-01-094 (2008).

A. Arpaia, A. Catania, A. Ferrari and E. Spessa, Development and application of an advanced numerical model for CR Piezo indirect acting injection systems, SAE Technical Paper 2010-01-1503 (2010).

V. Caika, T. Kammerdiener and N. Dörr, Operation of piezoelectric common rail injector with diesel and FTkerosene, SAE Technical Paper 2007-24-0070 (2007).

G. Dober, S. Tullis, G. Greeves, N. Milovanovic, M. Hardy and S. Zuelch, The impact of injection strategies on emissions reduction and power output of future diesel engines, SAE Technical Paper 2008-01-0941 (2008).

M. Chung, J. Kim, S. Kim, G. Sung and J. Lee, Effects of hydraulic flow and spray characteristics on diesel combustion in CR direct-injection engine with indirect acting Piezo injector, Journal of Mechanical Science and Technology, 29 (6) (2015) 1–9.

C. Arcoumanis and M. Baniasad, Analysis of consecutive fuel injection rate signals obtained by the Zeuch and Bosch methods, SAE Technical Paper 930921 (1993).

S. Detlev, Z. Stefan, H. Martin, G. Derk, R. W. Jorach and B. Nigel, Delphi common rail system with direct acting injector, MTZ Worldwide 10/2008, 69 (2008) 32–36.

J. B. Heywood, Internal combustion engine fundamentals, International Ed., Mc-Graw-Hill, New-York, USA (1988).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Jeong Park

Jinsu Kim received his Master’s degree in Mechanical Engineering, Soongsil University, Korea. He now serves as an Assistant Researcher in the Automotive Powertrain Laboratory at Soongsil University. His research interests are fuel injection system, low emission powertrain system, and real driving emission measurement system.

Jinwook Lee received his Ph.D. in Mechanical Engineering, Seoul National University, Korea. He is currently a Professor at Department of Mechanical Engineering, Soongsil University. His research interests are automotive powertrain system and clean energy technology for ICV, HEV and FCEV.

Rights and permissions

About this article

Cite this article

Kim, J., Kim, J., Jeong, S. et al. Effects of different piezo-acting mechanism on two-stage fuel injection and CI combustion in a CRDi engine. J Mech Sci Technol 30, 5727–5737 (2016). https://doi.org/10.1007/s12206-016-1143-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-016-1143-0