Abstract

Recently, in accordance with the increasing market demand for ultraprecision technology, a high precision multi-degree-of-freedom displacement measurement technology has become important for industrial applications such as the field of manufacturing and inspection because those physical quantities, linear and angular displacements, are key parameters for keeping and improving quality control of a production system. A number of instruments capable of precise multi-degree-of-freedom measurements have been built and some novel techniques have been introduced. The current state-of-art techniques for multi-degree-of-freedom motion error measurement in a linear stage using laser encoder-implemented system are reviewed. First, we summarize the basic principles behind the measurement technology of the motion error in a stage and simple encoder system. Next, the basic design principles of practical laser encoder system are discussed using the experience of past and existing cases to refer to the important points and the major scientific results. The current trends in the field are significantly discussed, including the novel techniques under construction and advanced technologies. Lastly, the future of multi-functional laser encoder-implemented system, highlighting the kinds of new science upcoming in the next few years, is discussed.

Similar content being viewed by others

References

A. H. Slocum, Precision machine design, Englewood Cliffs, NJ: Prentice-Hall (1992).

W. Gao, Precision Nanometrology: Sensors and Measuring Systems for Nanomanufacturing, Springer (2010).

J. G. Webster, The measurement, instrumentation, and sensors handbook, CRC Press LLC (1999).

O. Riemer, Advances in ultraprecision manufacturing, Proc. Jpn. Soc. Precis. Eng. (2011).

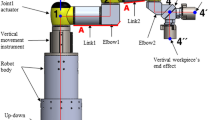

C. Lee, G. -H. Kim and S. -K. Lee, Design and construction of a single unit multi-function optical encoder for a six-degree-of-freedom motion error measurement in an ultraprecision linear stage, Meas. Sci. Technol., 22 (2011) 105901.

C. Lee, G. -H. Kim, D. -J. Lee and S. -K. Lee, A six-degreeof- freedom motion characterization of ballscrew-driven stage using a single unit of an optical encoder, Proc. 26 th ASPE Annual Meeting (2011).

C. Lee, G. -H. Kim and S. -K. Lee, Uncertainty Investigation of Grating Interferometry in Six-degree-of-freedom Motion Error Measurements, Int. J. Prec. Manuf. Eng., 13(9) (2012) 1509–1515.

C. Lee, G. -H. Kim and S. -K. Lee, Measurement of a Sixdegree- of-freedom Dynamic Characteristics using Angle Sensor-Implemented Grating Interferometry, J. Kor. Soc. Prec. Eng., 29(8) (2012) 1–7 (in Korean).

S. -R. Park, T. -K. Hoang and Seung-Han Yang, A new optical measurement system for determining the geometrical errors of rotary axis of a 5-axis miniaturized machine tool, J. Mech. Sci. Technol., 24(1) (2010) 175–179.

D. -M. Lee, Y. -T. Cha and S. -H. Yang, Analysis of eccentricity in the ball bar measurement, J. Mech. Sci. Technol., 24 (2010) 271–274.

W. -S. Kim, D. -J. Lee and S. -K. Lee, Influence of a high vaccum on the precise positioning using an ultrasonic linear motor, Rev. Sci. Instrum., 82(1) (2011) 015112.

J. -H. Kang, ChaBum Lee, J. -Y. Joo and S. -K. Lee, Phase-locked loop based on machine surface topography measurement using lensed fibers, Appl. Opt., 50(4) (2010) 460–467.

I. C. Song, S. K. Lee, B. H. Lee and S. H. Jeong, Absolute strain measurement using Fiber Bragg Grating sensors, Appl. Opt., 43(6) (2004) 1337–1341.

S. J. Jeong, S. K. Lee and S. H. Jeong, Beam alignment with the axis of a rotation stage for laser fabrication of micro circular structures, Opt. Laser Technol., 36 (2004) 401–408.

C. Lee, Design and construction of six degree-of-freedom motion error measurement system in a linear stage using grating interferometry, PhD Thesis, Gwangju Institute of Science and Technology (2012).

D. -M. Lee, Z. Zhu, K. -I. Lee and S. -H. Yang, Identification and measurement of geometric errors for a five-axis machine tool with a tilting head using a double ball-bar, Int. J. Prec. Eng. Manuf., 12(2) (2011) 337–342.

K. Hane, T. Endo, Y. Ito and M. Sasaki, A compact optical encoder with micromachined photodetector, J. Opt. A: Pure Appl. Opt., 3 (2001) 191–195.

JongHan Jin, Y. -J. Kim, Y. Kim and S. -W. Kim, Absolute distance measurements using the optical comb of a femto-second pulse laser, Int. J. Precis. Eng. Manuf., 8(4) (2007) 22–26.

J. Fraden, 4 th Ed. Handbook of modern sensors: Physics, Designs, and Applications, Springer (2010).

Materials from http://www.zygo.com.

The North American market for linear displacement sensors: optical encoder growth slower, new technologies emerge, Venture Development Corporation, Oct. 11 (2007).

A. Kimura, W. Gao, Y. Arai, Z. Lijiang, Design and construction of a two-degree-of-freedom linear encoder for nanometric measurement of stage position and straightness, Precis. Eng., 34 (2010) 145–155.

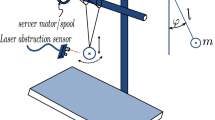

Y. Saito, Y. Arai and W.i Gao, Detection of three-axis angles by an optical sensor, Sens. Actuators A, 150 (2009) 175–183.

Y. Saito, Y. Arai and W. Gao, Investigation of an optical sensor for small tilt angle detection of a precision linear stage, Meas. Sci. Technol., 21 (2010) 054006.

Y. Saito, W. Gao, and S.i Kiyono, A single lens-micro angle sensor, Int. J. Precis. Eng. Manuf. 2 (2007) 14–19.

W. Gao, Y. Arai, A. Shibuya, S. Kiyono and C. H. Park, Measurement of multi-degree-of-freedom error motions of a precision linear air-bearing stage, Precis. Eng., 30 (2006) 96–103.

W. Gao, Y. Saito, H. Muto and Y. Shimizu, A three-axis autocollimator for detection of angular error motions of a precision stage, Annals of CIRP, Manuf. Technol., 60 (2011) 515–518.

Wei Gao, P. S. Huang, T. Yamada and S. Kiyono, A compact and sensitive two-dimensional angle probe for flatness measurement of large silicon wafers, Precis. Eng., 26 (2002) 396–404.

A. Kimura, Wei Gao and Satoshi Kiyono, Design and construction of a surface encoder with dual sine-grids, Int. J. Precis. Eng. Manuf., 8 (2007) 20–25.

W. Gao, S. Dejima and S. Kiyono, A dual-mode surface encoder for position measurement, Sens. Actuator A, 117 (2005) 95–102.

http://www.asme.org: ASME B5.57.

http://www.iso.org: ISO 230.

R. D. Gregory, Classical Mechanics: An undergraduate text, Cambridge University Press (2006).

J. S. Beggs, Kinematics, Talyor & Francis (1983).

O. Bottema and B. Roth, Theoretical Kinematics, Dover Publications (1990).

C. -H. Liu, W. -Y. Jywe and C. -K. Chen, Development of a simple system for the simultaneous measurement of pitch, yaw and roll angular errors of a linear stage, Int. J. Adv. Manuf. Technol., 26 (2005) 808–813.

C. -H. Liu, W. -Y. Jywe, C. K. Chen, W. H. Hsien, L. -H. Shyu, L. -W. Ji, V. -T.i Liu, T. -H. Hsu and C. -D. Chen, Development of a four-degree-of-freedom diffraction sensor, J. Phys., 48 (2006) 196–201.

J. -A. Kim, K. -C.n Kim, E. W. Bae, SooHyun Kim and Y. K. Kwak, Six-degree-of-freedom displacement measurement system using a diffraction grating, Rev. Sci. Instrum., 71(8) (2000) 3214–3219.

J. W. Kim, C. -S. Kang, J. -A. Kim, Taebong Eom, Mijung Cho and Hong Jin Kong, A compact system for simultaneous measurement of linear and angular displacements of nano-stages, Opt. Express, 15(24) (2007) 15759–15766.

K. C. Fan, M. J. Chen and W. M. Huang, A six-degree-of-freedom measurement system for the motion accuracy of linear stage, Int. J. Mach. Tools Manuf., 38(3) (1998) 155–164.

K. -C. Fan and M. -J. Chen, A 6-degree-of-freedom measurement system for the accuracy of X-Y stages, Precis. Eng., 24 (2000) 15–23.

ChaBum Lee, G. -H. Kim and S. -K. Lee, Measurement error and system of motion error, Patent registration No.10-1174000, Korea (2012).

C. -H. Liu, H. -L. Huang, and H. -W. Lee, Five-degrees-of-freedom diffractive laser encoder, Appl. Opt., 48(14) (2009) 2767–2777.

M. Madden, M. Aketagawa, Y. Ohkubo, S. Kimura, H. Maruyama, S. Higuchi and E. Okuyama, Proposal of concurrent measurement method for spindle radial, axial and angular motions using concentric grating interferometers, Int. J. Surf. Sci. Eng., 3(3) (2009) 242–252.

H. -L. Huang, C. -H. Liu, W. -Y. Jywe, M. -S. Wang and T. -H. Fang, Development of a three-degree-of-freedom laser linear encoder for error measurement of a high precision stage, Rev. Sci. Instrum., 78 (2007) 066103.

E. Hecht, 4 th Ed. Optics, Addison Wesley (2009).

G. R. Fowles, 2 nd Introduction to modern optics, Dover Publications (1989).

J. W. Goodman, 2 nd Introduction to Fourier optics, McGraw-Hill (2005).

T. Ohara, A new high precision position measurement system, PhD Thesis, MIT Mechanical Engineering (1995).

S. Makinouchi, T. Imai, A. Watanabe, J. Ong and T. Ohara, Introduction of SPPE-1000 scanning interference optical encoder, Materials from http://www.nanowave.com.

S. Makinouchi, T. Imai, A. Watanabe, T. Ohara and S. Wakui, A study on stabilization of scanning optical encoder — High stability position sensor using synchronous phase detection and compensation grating, J. Jpn. Soc. Precis. Eng., 76(9) (2010) 1049–1053 (in Japanese).

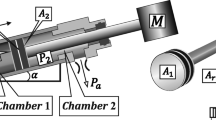

S. Makinouchi, A. Watanabe, M. Takasaki, T. Ohara, J. H. Ong and S. Wakui, An evaluation of a modulated laser encoder, Precis. Eng., 35 (2011) 302–308.

S. Makinouchi, A. Watanabe, M. Takasaki, T. Ohara and JinHock Ong, A short-range error evaluation of a wavelength modulation encoder, Proc. 26 th ASPE Annual Meeting (2011).

S. Makinouchi, T. Imai. A. Watanabe, T. Ohara, S. Wakui, A study of modulated interference laser encoder — new approach for a high resolution and high stability position measurement system, Proc. 24 th ASPE Annual Meeting (2009).

C. -C. Wu, Y. -C. Chen, C. -Kung Lee, Wen-Jack Wu and Sheyshi Lu, Design verifications of a linear laser encoder with high head-to-scale tolerance, Proc. SPIE, 3779(73) (1999).

Ching-Fen Kao, Sheng-Hua Lu and Mao-Hong Lu, High resolution planar encoder by retro-reflection, Rev. Sci. Instrum., 76 (2005) 085110.

C. -F. Kao, S. -H. Lu, H. -M. Shen and K. -C. Fan, Diffractive laser encoder with a grating in littrow configuration, Jpn. J. Appl. Phys., 47 (2008) 1833–1837.

K. K. Tan, Huixing X. Zhou and Tong Heng Lee, New interpolation method for quadrature encoder signals, IEEE Trans. Instrum. Meas., 51(5) (2002) 1073–1079.

P. L. M. Heydemann, Determination and correction of quadrature fringe measurement errors in interferometers, Appl. Opt., 20(19) (1981) 3382–3384.

K. P. Birch, Optical fringe subdivision with nanometric accuracy, Precis. Eng., 12(4) (1990) 33–47.

N. Hagiwara and H. Murase, A method of improving the resolution and accuracy of rotary encoders using a code compensation technique, IEEE Trans. Instrum. Meas., 41 (1992) 98–101.

T. Q. Banh, Y. Ohkubo, Y. Murai and M. Aketagawa, Active suppression of air refractive index fluctuation using the Fabry-perot cavity and a piezoelectric volume actuator, Appl. Opt., 50(1) (2011) 53–60.

Ki-Nam Joo, Jonathan D. Ellis, Jo W. Spronck and Robert H. Munnig Schmidt, Real-time wavelength corrected heterodyne laser interferometry, Precis. Eng., 35 (2011) 38–43.

J. H. Jin, Young-Jin Kim, Yunseok Kim and Seung-Woo Kim, Absolute distance measurements using the optical comb of a femtosecond pulse laser, Int. J. Precis. Eng. Manuf., 8(4) (2007) 22–26.

S. W. Hyun, Young-Jin Kim, Yunseok Kim, Jonghan Jin and Seung-Woo Kim, Absolute length measurement with the frequency comb of a femtosecond laser, Meas. Sci. Technol., 20 (2009) 095302.

Kazovsky R. G., Theory of tracking accuracy of laser systems, Opt. Eng., 22 (1983) 339–347.

Z. P. Barbaric, A. S. Marincic, L. M. Manojlovic, Measurement error estimation of light spot position on a quadrant photodiode, Proc. 16 th Telecomm. Forum (2008) 452–455.

J. C. Mallinson, The foundations of magnetic recording, 2nd Ed., Academic Press (1993).

H. Cho, Optomechatronics: Fusion of optical and mechatronic engineering, CRC Press Taylor & Francis (2006).

M. Aketagawa, K. Takada, P. Perkkumsup, Y. Togawa and H. Honda, Real-time atomic encoder using scanning tunneling microscope and regular crystalline surface, Meas. Sci. Technol., 17 (2006) 513–518.

M. Aketagawa, H. Honda, M. Ishige and C. Patamaporn, Two-dimensional encoder with picometre resolution using lattice spacing on regular crystalline surface as standard, Meas. Sci. Technol., 18 (2007) 342–349.

M. Aketagawa and Y. Ikeda, Nuttapong Tanyarat and masashi Ishige, Optical encoder calibration using lattice spacing and optical fringe derived from a scanning tunneling microscope and optical interferometer, Meas. Sci. Technol., 18 (2007) 503–509.

P. Chaikool, M. Aketagawa and E. Okuyama, A two-dimensional atom encoder using one lateral-dithered scanning tunneling microscope(STM) tip and a regular crystalline lattice, Meas. Sci. Technol., 20 (2009) 084006.

M. G. Moharam and T. K. Gaylord, Rigorous coupled-wave analysis of planar-grating diffraction, J. Opt. Soc. Am., 71 (1981) 811–818.

M. G. Moharam, Eric B. Grann, Drew A. Pommet and T. K. Gayload, Formulation for stable and efficient implementation of the rigorous coupled-wave analysis of binary gratings, J. Opt. Soc. Am., 12(5) (1995) 1068–1076.

M. G. Moharam, Drew A. Pommet, Eric B. Grann and T. K. Gayload, Stable implementation of the rigorous coupledwave analysis for surface-relief gratings: enhanced transmittance matrix approach, J. Opt. Soc. Am., 12(5) (1995) 1077–1086.

M. G. Moharam and T. K. Gaylord, Diffraction analysis of dielectric surface-relief gratings, J. Opt. Soc. Am., 72(10) (1982) 1385–1392.

ChaBum C. B. Lee, K. Hane, W. S. Kim and S. -K. Lee, Design of retrodiffraction gratings for polarizationinsensitive and polarization-sensitive characteristics by using the Taguchi method, Appl. Opt., 47(18) (2008) 3246–3253.

ChaBum Lee, T. Kuriyagawa and S. -K. Lee, Optimizing the fabrication process of a high-efficiency blazed grating through diamond scribing and molding, J. Micromech. Microeng., 20(5) (2010) 055028.

ChaBum Lee, K. Hane and S. -K. Lee, Optimization of sawtooth gratings by using RCWA and its fabrication on a slanted silicon substrate by Fast Atom Beam etching, J. Micromech. Microeng., 18 (2008) 045014.

D. -K. Woo, K. Hane and S. -K. Lee, High order diffraction grating using v-shaped groove with refractive and reflective surfaces, Opt. Express, 16(25) (2008) 21004–21011.

K. Ogata, 4 th Ed. System Dynamics, Prentice Hall (2003).

R. C. Dorf and R. H. Bishop, Modern Control Systems, Prentice Hall (2008).

G. -H. Kim, S. -G. Cho, W. -S. Kim and Sun-Kyu Lee, Switching control for nanopositioning of the ball-screw driven stage, Proc. 4 th International Conference on Positioning Technology (2008) 129–130.

S. -M. Kim, J. -H. Ha, S. -H. Jeong and Sun-Kyu Lee, Effect of joint condition on the dynamic behavior of grinding wheel spindle, Int. J. Mach. Tools Manuf., 41(12) (2001) 1749–1761.

R. -H. Wu and P. -C. Tung, Studies of stick-slip friction, presliding displacement, and hunting, J. Dyn. Sys. Meas. Control, 124 (2002) 111–117.

K. Sato, Trend of precision positioning technology, ABCM Symposium Series in Mechatronics, 2 (2006) 739–750.

H. -J. Kim and D. -E. Kim, Nano-scale friction: a review, Int. J. Precis. Eng. Manuf., 10(2) (2009) 141–151.

W. -S. Kim, C. -H. Yun and S. -K. Lee, Nano Positioning of a High Power Ultrasonic Linear Motor, Jpn. J. Appl. Phys., 47 (2008) 5687–5692.

H. -S. Choi and S. -K. Lee, Machining error compensation of external cylindrical grinding using thermally actuated rest, Mechatronics, 12(5) (2002) 643–656.

S. -M. Kim and S. -K. Lee, Prediction of thermo-elastic behavior in spindle bearing system considering surroundings, Int. J. Mach. Tools Manuf., 41(6) (2001). 809–831.

Y. Hwang, T. Kuriyagawa and S. -K. Lee, Wheel curve generation error of aspheric microgrinding in parallel grinding method, Int. J. Mach. Tools Manuf., 6(1) (2006) 59–64.

S. Futami., A. Furutani, Nanometer positioning and its micro-dynamics, Nanotechnology, 1(1) (1990) 31–37.

S. -K. Lee, J. -H. Yoo and M. -S. Yang, Effect of thermal deformation on machine tool slide guide motion, Tribology International, 36(1) (2003) 41–47.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Song Min Yoo

ChaBum Lee received a B.S in Mechanical Engineering from Chung-Ang University in 2006 and an M.S and Ph.D from Gwangju Institute of Science and Technology in 2008 and 2012, respectively. His research interests include optical measurement, analysis and fabrication of diffractive optical components, and design of optical components.

Sun-Kyu Lee received a B.S in Mechanical Engineering from Seoul National University in 1980, and a Doctor of Engineering in Mechanical Engineering for Production from Tokyo Institute of Technology in 1991. Dr. Lee was a part of research endeavors in the field of machine tool for high speed machining, and he has specialty in the rolling bearing-spindle design and manufacturing. Dr. Lee is currently a professor at the School of Mechatronics in Gwangju Institute of Science and Technology, Korea. His research interests include ultraprecision machine design and precision machining, and precision measurement.

Rights and permissions

About this article

Cite this article

Lee, C., Lee, SK. Multi-degree-of-freedom motion error measurement in an ultraprecision machine using laser encoder — Review. J Mech Sci Technol 27, 141–152 (2013). https://doi.org/10.1007/s12206-012-1217-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-012-1217-6