Abstract

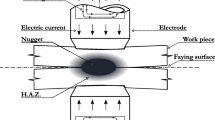

More high strength steel (HSS) sheets are being applied in the automobile industry to improve safety and fuel efficiency. When HSS is spot welded, the strength of the welded-joint is usually determined by the attributes of the weld nugget. However, it is difficult to obtain the circular nugget and to establish the relationship between the weld attributes and welding quality because of a large number of variables and experimental uncertainty. In the paper, the numerical analysis model of tensile-shear strength test for HSS spot welds was established. And the critical ellipticity of the elliptical spot weld was determined through finite element analysis. Quantitative relationship between elliptical weld attributes and weld strength was investigated statistically using the Latin hypercube and regression analysis method. The sheet thickness, nugget ellipticity, hardness radio and yield strength have the most influential attributes in affecting welding quality. The research results can be used as a guideline for HSS resistance spot welding design.

Similar content being viewed by others

References

Tumuluru M D. Resistance spot welding of coated high-strength dual phase steels [J]. Welding Journal, 2006, 85(8): 31–37.

Marya M, Gayden X Q. Development of requirements for resistance spot welding dual-phase (DP600) steels part 1—the cause of interfacial fracture [J]. Welding Journal, 2005, 84(11): 172–182.

Pouranvari M, Asgari H R, Mosavizadch S M, et al. Effect of weld nugget size on overload failure mode of resistance spot welds [J]. Science and Technology of Welding and Joining, 2007, 12(3): 217–225.

Chang B H, Shi Y W, Dong S J. Comparative studies on stresses in weld-bonded, spot-welded and adhesivebonded joints [J]. Journal of Materials Processing Technology, 1999, 87(1–3): 230–236.

Chao Y J. Ultimate strength and failure mechanism of resistance spot weld subjected to tensile, shear, or combined tensile/shear loads [J]. ASME Journal of Engineering Materials and Technology, 2003, 125(4): 125–132.

Marya M, Wang K, Hector L G, et al. Tensile-shear forces and fracture modes in single and multiple weld specimens in dual-phase steels [J]. Journal of Manufacturing Science and Engineering, 2006, 128(2): 287–298.

Zhou M, Zhang H, Hu S J. Relationship between quality and attributes of spot welds [J]. Welding Journal, 2003, 82(4): 72–77.

Keller F, Smith D W. Correlation of the strength and structure of spot welds in aluminum alloys [J]. Welding Journal, 1944, 23(1): 23–26.

McMaster R C, Lindrall F C. The interpretation of radiographs of spot welds in alclad 24S-T and 75ST aluminum alloys [J]. Welding Journal, 1946, 25(8):707–723.

Heuschkel J. The expression of spot-weld properties [J]. Welding Journal, 1952, 31(10): 931–943.

Sawhill J M, Baker J C. Spot weldability of highstrength sheel steets [J]. Welding Journal, 1980, 59(1):19–30.

Bourges P H, Jubin L, Bocquet P. Prediction of mechanical properties of weld metal based on some metallurgical assumptions [J]. Mathematical Modeling of Weld Phenomena, 1995, 29(9): 201–212.

Zhou M, Hu S J, Zhang H. Critical specimen sizes for tensile-shear testing of steel sheets [J]. Welding Journal, 1999, 78(9): 305–312.

Huh H, Kang W J. Electrothermal analysis of electric resistance spot welding processed by a 3-D finite element method [J]. Journal of Materials Processing Technology, 1997, 63(1–3): 672–677.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (No. 50575140)

Rights and permissions

About this article

Cite this article

Yang, Hg., Zhang, Ys., Lai, Xm. et al. Relationship between quality and attributes of elliptical spot welds of high strength steel. J. Shanghai Jiaotong Univ. (Sci.) 13, 734–738 (2008). https://doi.org/10.1007/s12204-008-0734-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-008-0734-z