Abstract

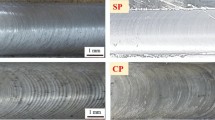

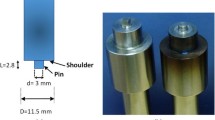

The influence of rapid plastic deformation in the generation of welding heat during friction stir welding (FSW), supplementing the frictional heat generation by the tool shoulder, forms the thrust of the present investigation. Several researchers have highlighted the role of tool shoulder in the generation of frictional heat and suggested that the tool-material interface friction as the sole mechanism for heating. The configuration of tool pin profile is seldom studied for its contribution to welding heat through rapid plastic deformation at high strain rates (103/s), especially while welding thick plates. An attempt has been made to understand the dependence of deformation heat generation with different tool pin profiles in welding 5 mm thick AA2014-T6 aluminum alloy, maintaining the same swept volume during the tool rotation. An attempt has also been made to correlate the influence of process response variables such as force and torque acting on the tool pin. To quantify the physical influence of tool pin profile, temperature measurements were made in the region adjacent to the rotating pin, close to nugget in the thermo-mechanically affected zone (TMAZ). It has been observed that the temperature rises at a relatively rapid rate in the case of hexagonal tool pin compared to the welds produced employing other tool pin profiles. It is observed that during FSW, extensive deformation experienced at the nugget zone and the evolved microstructure strongly influences the mechanical properties of the joint. The present study is also aimed at understanding the influence of tool profile on the microstructural changes and the associated mechanical properties. Transverse tensile samples failed at the nugget/TMAZ boundary due to localized softening. Hexagonal tool pin profile welds have shown higher tensile strength, low TMAZ width, and high nugget hardness compared to other tool pin profile welds.

Similar content being viewed by others

References

W.M. Thomas, E.D. Nicholas, J.C. Needham, M.G. Murch, P. Temple Smith, and C.J. Dawas, Int. Patent Appl. No. PCT/GB92/02203 and GB Patent Appl. No. 9125978.8, Dec 1991, U.S. Patent Appl. No. 5460317, Oct 1995

R. Nandan, T. DebRoy, and H.K.D.H. Bhadeshia, Recent Advances in Friction-Stir Welding: Process, Weldment Structure and Properties, Prog. Mater. Sci., 2008, 53, p 980–1023

Y.S. Sato, H. Kokowa, M. Enomoto, and S. Jogan, Microstructural Evolution of 6063 Aluminum During Friction-Stir Welding, Metall. Mater. Trans. A, 1999, 30A, p 2429–2437

S. Xu, X. Deng, A.P. Reynolds, and T.U. Seidel, Finite Element Simulation of Material Flow in Friction Stir Welding, Sci. Technol. Weld. Join., 2001, 6(3), p 191–193

P.L. Threadgill, A.J. Leonard, H.R. Shercliff, and P.J. Withers, Friction Stir Welding of Aluminium Alloys, Int. Mater. Rev., 2009, 54(2), p 49–93

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R, 2005, 50, p 1–78

P.A. Colegrove, H.R. Shercliff, and R. Zettler, Model for Predicting Heat Generation and Temperature in Friction Stir Welding from the Material Properties, Sci. Technol. Weld. Join., 2007, 12(4), p 284–297

L. Fratini, G. Buffa, D. Palmeri, J. Hua, and R. Shivpuri, Material Flow in FSW of AA7075-T6 Butt Joints: Numerical Simulations and Experimental Verifications, Sci. Technol. Weld. Join., 2006, 11(4), p 412–421

M. Mahoney, C. Rhodes, J. Flintoff, W. Bingel, and R. Spurling, Properties of Friction-Stir-Welded 7075 T651 Aluminium, Metall. Mater. Trans. A, 1998, 29(7), p 1955–1964

S. Mukherjee and A.K. Ghosh, Flow Visualization and Estimation of Strain and Strain-Rate During Friction Stir Process, Mater. Sci. Eng. A, 2010, 527(20), p 5130–5135

E.D. Nicholas and W.M. Thomas, A Review of Friction Processes for Aerospace Applications, Int. J. Mater. Prod. Technol., 1998, 13(1–2), p 45–55

I. Shigematsu, Y.J. Known, K. Suzuki, T. Imai, and N. Saito, Joining of 5083 and 6061 Aluminum Alloys by Friction Stir Welding, J. Mater. Sci. Lett., 2003, 22(5), p 353–356

W.B. Lee, Y.M. Yeon, and S.B. Jung, The Improvement of Mechanical Properties of Friction-Stir-Welded A356 Al Alloy, Mater. Sci. Eng. A, 2003, 355(1–2), p 154–159

J. Yan, M.A. Sutton, and A.P. Reynolds, Process-Structure-Property Relationships for Nugget and Heat Affected Zone Regions of AA2524-T351 Friction Stir Welds, Sci. Technol. Weld. Join., 2005, 10(6), p 725–736

A. Arora, A. De, and T. Deb Roy, Towards Optimum Friction Stir Welding Tool Shoulder Diameter, Scripta Mater., 2011, 64(1), p 9–12

K. Colligan, Material Flow Behavior During Friction Stir Welding of Aluminum, Weld. J. (Suppl.), 1999, p 229–237

C.B. Fuller, Friction Stir Tooling: Tool Materials and Design, Friction Stir Welding and Processing, R.S. Mishra, M.W. Mahoney, Ed., ASM International, Materials Park, 2007, p 7–36

Arora, R. Nandan, A.P. Reynolds, and T. DebRoy, Torque, Power Requirement and Stir Zone Geometry in Friction Stir Welding Through Modeling and Experiments, ScriptaMater., 2009, 60, p 13–16

W. Woo, H. Choo, D. Brown, and Z. Feng, Influence of the Tool Pin and Shoulder on Microstructure and Natural Aging Kinetics in a Friction-Stir-Processed 6061-T6 Aluminum Alloy, Metall. Mater. Trans. A, 2007, 38(1), p 69–76

L. Ke, L. Xing, and J. Indacochea, Material Flow Patterns and Cavity Model in Friction-Stir Welding of Aluminum Alloys, Metall. Mater. Trans. B, 2004, 35(1), p 153–160

J.H. Ouyang and R. Kovacevic, Material Flow and Microstructure in the Friction Stir Butt Welds of the Same and Dissimilar Aluminium Alloys, J. Mater. Eng. Perform., 2002, 11(1), p 51–63

G.R. Cui, Z.Y. Ma, and S.X. Li, Periodical Plastic Flow Pattern in Friction Stir Processed Al-Mg Alloy, Scripta Mater., 2008, 58, p 1082–1085

O. Friggard, O. Grong, B. Bjorneklett, and O.T. Middling, Proceedings of the 1st International Symposium on Friction Stir Welding, Thousand Oaks, CA, USA, June 1999, TWI

Y. Zhao, S. Lin, L. Wu, and F. Qu, The Influence of Pin Geometry on Bonding and Mechanical Properties in Friction Stir Weld 2014 Al Alloy, Mater. Lett., 2005, 59(23), p 2948–2952

W.M. Thomas, K.I. Johnson, and C.S. Wiesner, Friction Stir Welding—Recent Developments in Tool and Process Technologies, Adv. Eng. Mater., 2003, 5, p 485–490

R.M. Leal, C. Leitao, A. Loureiro, D.M. Rodrigues, and P. Vilac, Material Flow in Heterogeneous Friction Stir Welding of Thin Aluminium Sheets: Effect of Shoulder Geometry, Mater. Sci. Eng. A, 2008, 498, p 384–391

K. Kumar, S.V. Kailas, and T.S. Srivatsan, The Role of Tool Design in Influencing the Mechanism for the Formation of Friction Stir Welds in Aluminum Alloy 7020, Mater. Manuf. Process., 2011, 26(7), p 915–921

D.G. Hattingh, C. Blignault, T.I. Van Niekerk, and M.N. James, Characterization of the Influences of FSW Tool Geometry on Welding Forces and Weld Tensile Strength Using an Instrumented Tool, J. Mater. Process. Technol., 2008, 203(1–3), p 46–57

Y.J. Chao, X. Qi, and W. Tang, Heat Transfer in Friction Stir Welding: Experimental and Numerical Studies, ASME J. Manuf. Sci., 2003, 125, p 138–145

M. Song and R. Kovacevic, Thermal Modeling of Friction Stir Welding in a Moving Coordinate System and Its Validation, Int. J. Mach. Tools Manuf., 2003, 43(6), p 605–615

C.Gallais, A. Denquin, A. Pic, A. Simar, T. Pardoen, and Y. Brechet, Modelling the Process Parameters, Microstructural Evolutions and Mechanical Behaviour in a Friction Stir Welded 6xxx Aluminium Alloys, Proceedings of the 5th International Symposium on Friction Stir Welding, Sept 2004 (Metz, France) TWI

M. Murayama, Z. Horita, and K. Hono, Microstructure of Two-Phase Al-1.7 at% Cu Alloy Deformed by Equal-Channel Angular Pressing, Acta Mater., 2001, 49, p 21–29

K. Venkateswarlu, M. Chakraborty, and B.S. Murty, Influence of Thermo-mechanical Processing of Al-5Ti-1B Master Alloy on Its Grain Refining Efficiency, Mater. Sci Eng. A, 2004, 364, p 75–83

K. Surekha, B.S. Murty, and K. Prasad Rao, Effect of Processing Parameters on the Corrosion Behaviour of Friction Stir Processed AA 2219 Aluminium Alloy, Solid State Sci., 2009, 11, p 907–917

P. Venkata Ramana, G. Madhusudhan Reddy, and T. Mohandas, Microstructure, Hardness and Residual Stress Distribution in Maraging Steel Gas Tungsten Arc Weldments, Sci. Technol. Weld. Join., 2008, 13(4), p 388–394

P. Venkata Ramana, G. Madhusudhan Reddy, and A.V.S.S.K.S. Gupta, Influence of Parent Metal Mechanical Properties on Those of the Different Ultra-High-Strength Steel Electron Beam Welds, Steel Grips, 2009, 7, p 441–448

G. Madhusudhan Reddy, P. Mastanaiah, K. Satya Prasad, and T. Mohandas, Microstructure and Mechanical Property Correlations in AA 6061 Aluminium Alloy Friction Stir Welds, Trans. IIM, 2009, 62(1), p 49–58

C. Munoz, G. Ruckert, B. Huneau, X. Sauvage, and S. Marya, Comparison of TIG Welded and Friction Stir Welded Al-4.5Mg-0.26Sc Alloy, J. Mater. Process. Technol., 2008, 197, p 337–343

J. Zhao, F. Jiang, H. Jian, K. Wen, L. Jiang, and X. Chen, Comparative Investigation of Tungsten Inert Gas and Friction Stir Welding Characteristics of Al-Mg-Sc Alloy Plates, Mater. Des., 2010, 31, p 306–311

M. Nunn, D. Bertaso, and W Xu, Comparison of Friction stir and MIG Welding—Preliminary Small Scale Static and Dynamic Tests, 2004, TWI Report No: 14357/1/04

P.A. Colegrove and H.R. Shercliff, CFD Modelling of Friction Stir Welding of Thick Plate 7449 Aluminium Alloy, Sci. Technol. Weld. Join., 2006, 11(4), p 429–444

P.A. Colegrove and H.R. Shercliff, Development of Trivex Friction Stir Welding Tool. Part 1—Two-Dimensional Flow Modelling and Experimental Validation, Sci. Technol. Weld. Join., 2004, 9(4), p 345–351

C.I. Chang, C.J. Lee, and J.C. Huang, Relationship Between Grain Size and Zener-Holloman Parameter During Friction Stir Processing in AZ31Mg Alloys, Scripta Mater., 2004, 51, p 509–514

S.F. Medina and C.A. Hernandez, General Expression of the Zener-Hollomon Parameter as a Function of the Chemical Composition of Low Alloy and Microalloyed Steels, Acta Mater., 1996, 44(1), p 137–148

A. Deschamps, F. Livet, and Y. Brechet, Influence of Pre-deformation on Ageing in an Al-Zn-Mg alloy-I. Microstructure Evolution and Mechanical Properties, Acta. Mater., 1998, 47(1), p 281–292

K. Elangovan and V. Balasubramanian, Influences of Tool Pin Profile and Welding Speed on the Formation of Friction Stir Processing Zone in AA2219 Aluminium Alloy, J. Mater. Process. Technol., 2008, 200, p 163–175

Acknowledgments

The authors would like to thank Dr. G. Malakondaiah, Distinguished Scientist & Director, Defence Metallurgical Research laboratory (DMRL), Hyderabad and Dr. Amol A. Ghokale, Outstanding Scientist, DMRL for their constant encouragement and permission to publish this work. One of the authors (Mr. K. Ramanjaneyulu) expresses his gratitude to the management of MGIT, Hyderabad for their support in carrying out this work. Financial assistance from Defence Research and Development Organization (DRDO) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ramanjaneyulu, K., Madhusudhan Reddy, G., Venugopal Rao, A. et al. Structure-Property Correlation of AA2014 Friction Stir Welds: Role of Tool Pin Profile. J. of Materi Eng and Perform 22, 2224–2240 (2013). https://doi.org/10.1007/s11665-013-0512-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0512-4