Abstract

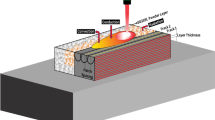

Solvent debinding is one of the processes widely adopted by the powder injection molding industry. Despite the inherent advantages of short debinding cycles, the low temperature employed, and the low investment in processing equipment, dimensional control is still a challenge to the further promotion of this technology. The objective of this study was to investigate the causes of the tolerance-control problems by measuring the in-situ dimensional change and deformation behavior of powder injection-molded (PIM) specimens during debinding, using a self-designed laser dilatometer. Swelling and sagging were found when compacts were immersed in the solvent. Three major factors were found to be responsible for the expansion of the specimens: dissolution of soluble binder into the solvent, reaction between the insoluble binder and solvent, and thermal expansion due to the temperature rise from the solvent bath. The amounts of expansion and sagging were related to the thickness of the sample, the amount of the binder, and the temperature employed. These in-situ measurements on the dimensional change help explain how defects such as slumping, cracking, and distortion come about during debinding and provide some guidelines in selecting processing parameters and in designing binder compositions.

Similar content being viewed by others

References

K.P. Johnson: U.S. Patent No. 4,765,950, 1988.

R.E. Wiech, Jr.: U.S. Patent No. 4,197,118, 1980.

R.M. German: Powder Injection Molding, Metal Powder Industries Federation, Princeton, NJ, 1990, pp. 321–46.

K.S. Hwang: Rev. Part. Mater., 1996, vol. 4, pp. 71–104.

R.M. German and A. Bose: Injection Molding of Metals and Ceramics, Metal Powder Industries Federation, Princeton, NJ, 1997, pp. 175–218.

K.S. Hwang and Y.M. Hsieh: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 245–53.

S.T. Lin and R.M. German: Powder Metall. Int., 1989, vol. 21 (5), pp. 19–24.

H.E. Amaya: in Advances in Powder Metallurgy and Particulate Materials—1991, E.R. Andreotti and P.J. McGeehan, eds., Metal Powder Industries Federation, Princeton, NJ, 1991, vol. 1, pp. 233–46.

D.S. Tsai and W.W. Chen: Ceram. Int., 1995, vol. 21, pp. 257–64.

S.C. Hu and K.S. Hwang: P/M Science and Technology Briefs, 1999, vol. 1 (2), pp. 27–30.

N.F. Liau and S.T. Lin: Mater. Manufacturing Processes, 1997, vol. 12(24), pp. 661–71.

F.W. Billmeyer, Jr.: Textbook of Polymer Science, John Wiley and Sons, Inc., New York, NY, 1984, pp. 151–52.

H.K. Lin and K.S. Hwang: Acta Mater., 1998, vol. 46 (12), pp. 4303–09.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hu, S.C., Hwang, K.S. Length change and deformation of powder injection-molded compacts during solvent debinding. Metall Mater Trans A 31, 1473–1478 (2000). https://doi.org/10.1007/s11661-000-0265-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-000-0265-1