Abstract

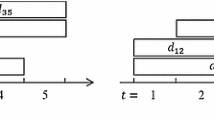

In this paper, we study a structure issued from a real case. Raw materials (RMs) are sent by suppliers to a distribution center (DC) and then transported to a unique plant where they can be stored. The inventory capacity is limited in the plant as well as in the DC. The transportation capacity between the DC and the plant is also limited. The objective is to determine the flows between suppliers and the DC, and from the DC to the plant in order to satisfy the demand during the planning horizon while minimizing the global cost. A mixed-integer programming (MIP) formulation is presented and a Lagrangean relaxation solution procedure is proposed. Computational experiments are carried out.

Similar content being viewed by others

References

Akbalik A., Kébé S., Penz B., Sbihi N. (2008) Exact methods and heuristics for the simultaneous optimization of a two echelon inbound supply chain. International Transactions in Operational Research 15: 195–214

Arntzen B., Brown G., Harrison T., Trafton L. (1995) Global supply chain management at digital equipement corporation. Interfaces 25: 69–93

Beasley J. E. (1993) Lagrangian relaxation. In: Reeves C. R. (eds) Modern heuristic techniques for combinatorial problem. John Wiley & Sons, New York, pp 243–303

Brahimi N., Dauzère-Pérès S., Najid N., Nordli A. (2006) Single item lot sizing problems. European Journal of Operational Research 168(1): 1–16

Chen H., Chu C. (2003) A Lagrangian relaxation approch for supply chain planning with order/setup costs and capacity constraints. Journal of Systems Science and Systems Engineering 12: 98–110

Dhaenens-Flipo C., Finke G. (2001) An integrated model for an industrial production-distribution problem. IIE Transactions 33(9): 705–715

Gnoni M., Iavagnilio R., Mossa G., Mummolo G., Leva A. D. (2003) Production planning of a multi-site manufacturing system by hybrid modelling: A case study from the automotive industry. International Journal of Production Economics 85: 251–262

Haq N., Vrat P., Kanda A. (1991) An integrated production-inventory-distribution model for manufacture of urea: A case. International Journal of Production Economics 39: 39–49

Jayaraman V., Pirkul H. (2001) Planning and coordination of production and distribution facilities for multiple commodities. European Journal of Operational Research 133: 394–408

Kaminsky P., Simchi-Levi D. (2003) Production and distribution lot sizing in a two stage supply chain. IEE Transactions 35(11): 1065–1075

Matta R., Miller T. (2004) Production and inter-facility transportation scheduling for a process industry. European Journal of Operational Research 158: 72–88

Robinson E., Lawrence F. (2004) Coordinated capacitated lot-sizing problem with dynamic demand: A Lagrangian heuristic. Decision Sciences 35: 25–53

Sambasivan M., Yahya S. (2005) A Lagrangean-based heuristic for multiplant, multi-item, multi-period capacitated lot-sizing problems with inter-plant transfers. Computers & Operations Research 32: 537–555

Samiento A., Nagi R. (1999) A review of integrated analysis of poduction–distribution systems. IIE Transactions 31: 1061–1074

Sharma R. (1990) Modelling a fertiliser distribution system. European Journal of Operational Research 51: 24–34

Shaw D., Wagelmans A. (1998) An algorithm for single-item capacitated economic lot sizing with piecewise linear production costs and general holding costs. Management Science 44(6): 831–838

van Hoesel S., Romeijn H., Morales D., Wagelmans A. (2005) Integrated lot sizing in serial supply chains with production capacities. Management Science 51(11): 1706–1719

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kébé, S., Sbihi, N. & Penz, B. A Lagrangean heuristic for a two-echelon storage capacitated lot-sizing problem. J Intell Manuf 23, 2477–2483 (2012). https://doi.org/10.1007/s10845-011-0514-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-011-0514-8