Abstract

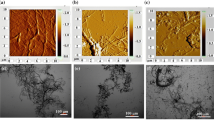

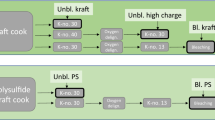

The present work studies the feasibility of wheat soda pulp as a raw material for the fabrication of cellulose nanofibres and their application as an additive in papermaking. Wheat straws were cooked under alkaline conditions and the resulting pulp was used as a raw material for the production of lignocellulosic nanofibres (LCNF). Nanofibres were fabricated by intense mechanical beating followed by high-pressure homogenization. The produced LCNF were characterized and applied to papermaking slurry based also on wheat straw soda pulp. Paper sheets made thereof were analysed for their physical and mechanical properties. The results indicated that paper strength was improved after addition of LCNF, whereas density increased and porosity was reduced. These improvements in properties (except the Tear Index) are significant because they were achieved using LCNF with lower fibrillation degree compared to previous works where chemically pre-treated LCNF were used as reinforcement.

Similar content being viewed by others

References

Afra E, Yousefi H, Hadilam MH, Nishino T (2013) Comparative effect of mechanical beating and nanofibrillation on paper properties made from bagasse and softwood pulps. Carbohydr Polym 97:725–730

Alcalá M, González I, Boufi S, Vilaseca F, Mutjé P (2013) All-cellulose composites from unbleached hardwood kraft pulp reinforced with nanofibrillated cellulose. Cellulose 20:2909–2921

Alila S, Besbes I, Rei Vilar M, Mutjé P, Boufi S (2013) Non-woody plants as raw materials for production of microfibrillated cellulose (MFC): a comparative study. Ind Crop Prod 41:250–259

Ankerfors M (2015) Microfibrillated cellulose: energy-efficient preparation techniques and applications in paper. Doctoral Thesis, KTH Royal Institute of Technology

Besbes I, Rei Vilar M, Boufi S (2011) Nanofibrillated cellulose from Alfa, Eucalyptus and Pine fibres: preparation, characteristics and reinforcing potential. Carbohydr Polym 86:1198–1206

Brodin FW, Gregersen ØW, Syverud K (2014) Cellulose nanofibrils: challenges and possibilities as paper additive or coating material. Nor Pulp Pap Res J 29(1):156–166

Carrasco F, Mutje P, Pelach MA (1996) Refining of bleached cellulosic pulps: characterization by application of the colloidal titration technique. Wood Sci Technol 30(4):227–236

Carrasco F, Mutjé P, Pelach MA (1998) Control of retention in paper-making by colloid titration and zeta potential techniques. Wood Sci Technol 32(2):145–155

Carvajal M, Mota C, Alcaraz-López C, Iglesias M, Martínez Ballesta MC (2008) Investigación sobre la absorción de CO2 por los cultivos más representativos. Accessed Nov 2014

Chaker A, Alila S, Mutjé P, Rei Vilar M, Boufi S (2013) Key role of the hemicelluloses content and the cell morphology on the nanofibrillation effectiveness of cellulose pulp. Cellulose 20:2863–2875

Confederation of European Paper Industries. Key statics 2010. www.cepi.org. Accessed Nov 2014

Delgado-Aguilar M, González I, Pèlach MA, De La Fuente E, Negro C, Mutjé P (2014) Improvement of deinked old newspaper/old magazine pulp suspensions by means of nanofibrillated cellulose addition. Cellulose 22(1):789–802

Eriksen Ø, Syverud K, Gregersen Ø (2008) The use of microfibrillated cellulose produced from kraft pulp as strength enhancer in TMP paper. Nor Pulp Pap Res J 23(3):299–304

Ferrer A, Quintana E, Filpponen I, Solala I, Vidal T, Rodríguez A, Laine J, Rojas OJ (2012) Effect of residual lignin and heteropolysaccharides in the nanofibrillar cellulose and nanopaper from wood fibers. Cellulose 19:2179–2193

García Hortal JA (2007) Fibras papeleras. Universidad Politécnica Cataluña, Barcelona

González I, Boufi S, Pèlach M, Alcalá M, Vilaseca F, Mutjé P (2012) Nanofibrillated cellulose as paper additive in eucalyptus pulps. BioResources 7(4):5167–5180

González I, Alcalá M, Arbat G, Vilaseca F, Mutjé P (2013) Suitability of rapeseed chemithermomechanical pulp as raw material in papermaking. BioResources 8(2):1697–1708

González I, Alcala M, Chinga-Carrasco G, Vilaseca F, Boufi S, Mutjé P (2014) From paper to nanopaper: evolution of mechanical and physical properties. Cellulose 21(4):2599–2609

González-García S, Moreira MT, Artal G, Ll Maldonado, Feijoo G (2010) Environmental impact assessment of non-wood based pulp production by soda-anthraquinone pulping process. J Clean Prod 18(2):137–145

Henriksson M, Henriksson G, Berglund LA, Lindtsröm T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polym J 43:3434–3441

Henriksson M, Berglund LA, Isaksson P, Lindström T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9:1579–1585

Janardhnan S, Sain MM (2006) Isolation of cellulose microfibrils—an enzymatic approach. BioResources 1(2):176–188

Naderi A, Lindström T, Sundström J (2015) Repeated homogenization, a route for decreasing the energy consumption in the manufacturing process of carboxymethylated nanofibrillated cellulose? Cellulose 22(2):1147–1157

Nogi M, Iwamoto S, Nakagaito AN, Yano H (2009) Optically transparent nanofiber paper. Adv Mater 21:1595–1598

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941

Rodríguez A, Sánchez R, Requejo A, Ferrer A (2010) Feasibility of rice straw as a raw material for the production of soda cellulose pulp. J Clean Prod 18:1084–1091

Rouger J, Mutjé P (1984) Correlation between the cellulose fibres beating and the fixation of a soluble cationic polymer. Br Polym J 16(2):83–86

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibres prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8:2485–2491

Solala I, Volperts A, Andersone A, Dizhbite T, Mironova-Ulmane N, Vehniäinen A, Pere J, Vuorinen T (2011) Mechanoradical formation and its effects on birch kraft pulp during the preparation of nanofibrillated cellulose with Masuko refining. Holzforschung 66:477–483

Spence K, Venditti RA, Rojas OJ, Habibi Y, Pawlak JJ (2011) A comparative study of energy consumption and physical properties of microfibrillated cellulose produced by different processing methods. Cellulose 18:1097–1111

Taipale T, Österberg M, Nykänen A, Ruokolainen J, Laine J (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17:1005–1020

Turbak A, Snyder F, Sandberg K (1983) Microfibrillated cellulose: a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci Appl Polym Symp 37:815–827

Vargas F, González Z, Sánchez R, Jiménez L, Rodríguez A (2012) Straw pulps for packaging. BioResources 7(3):4161–4170

www.fao.org. Accessed Nov 2014

Wågberg L, Decher G, Norgren M, Lindström T, Ankerfors M, Axnäs K (2008) The build-up of polyelectrolyte multilayers of microfibrillated cellulose and cationic polyelectrolytes. Langmuir 24:784–795

Acknowledgments

The authors are grateful to Spain’s DGICyT, MICINN for funding this research within the framework of the Projects CTQ2013-46804-C2-2-R.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Espinosa, E., Tarrés, Q., Delgado-Aguilar, M. et al. Suitability of wheat straw semichemical pulp for the fabrication of lignocellulosic nanofibres and their application to papermaking slurries. Cellulose 23, 837–852 (2016). https://doi.org/10.1007/s10570-015-0807-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0807-8