Abstract

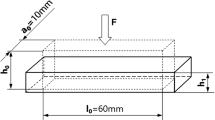

Complete experimental investigation on the workability behavior of sintered plain carbon steel cylindrical preforms with carbon contents of 0%, 0.35%, 0.75%, and 1.1%, under cold upsetting, has been studied in order to understand the influence of carbon content on the workability process. The abovementioned powder metallurgy sintered preforms with constant initial theoretical density of 84% and aspect ratio of 0.4 were prepared using a suitable die set assembly on a 1 MN capacity hydraulic press and sintered for 90 min at 1,200°C. Each sintered preform was cold upset under nil/no frictional constraint. Under triaxial stress state condition, densification, axial stress, hoop stress, hydrostatic stress, effective stress, and formability stress index against axial strain relationship were established and presented in this work. Further, attained density is considered to establish formability stress index and various stress ratio parameters’ behavior.

Similar content being viewed by others

References

Huang CC, Cheng JH (2004) An investigation into the forming limits of sintered porous materials under different operational conditions. J Mater Process Technol 148:382–393

Chandramouli R, Pandey KS, Kandavel TK, Ashokkumar T, Shanmugasundaram D (2007) Influence of material flow constraints during cold forming on the deformation and densification behaviour of hypoeutectoid P/M steel ring preforms. Int J Adv Mfg Technol 31:926–932

Zhang XQ, Peng YH, Li MQ, Wu SC, Ruan XY (2000) Study of workability limits of porous materials under different upsetting conditions by compressible rigid plastic finite element method. J Mater Engng Perform 9:164–169

Whang BB, Kobayashi S (1990) Deformation characterization of powdered compacts in compaction. Int J Mach Tools Mfg 30:309–323

Kandavel TK, Chandramouli R, Ravichandran M (2010) Experimental study on the plastic deformation and densification characteristics of some sintered and heat treated low alloy powder metallurgy steels. Mater Des 31:485–492

Narayanasamy R, Ramesh T, Pandey KS (2005) Some aspects on workability of aluminium–iron powder metallurgy composite during cold upsetting. Mater Sci Eng, A 391:418–426

Rahman MA, El-Sheikh MN (1995) Workability in forging of powder metallurgy compacts. J Mater Process Technol 54:97–102

El-Domiatry A, Shaker M (1991) A note on the workability of porous-steel preforms. J Mater Process Technol 25:229–233

Qin XP, Hua L (2007) Deformation and strengthening of sintered ferrous material. J Mater Process Technol 188:694–697

Kuhn HA (1978) Powder metallurgy processing. Academic, New York

Taha MA, El-Mahallawy NA, El-Sabbagh AM (2008) Some experimental data on workability of aluminium-particulate-reinforced metal matrix composites. J Mater Process Technol 202:380–385

Doraivelu SM, Gegel HL, Gunasekera JS, Malas JC, Morgan JT, Thomas JF Jr (1984) New yield function for compressible P/M materials. Int J Mech Sci 26:527–535

Kuhn HA, Downey CL (1974) How flow and fracture affect design of preforms for powder forging. Int J Powder Metall Powder Technol 10:59–66

Bao Y (2005) Dependence of ductile crack formation in tensile test on stress triaxiality, stress and strain ratios. Eng Fract Mech 72:505–522

Bao Y, Wierzbicki T (2004) On fracture locus in the equivalent strain and stress triaxiality space. J Eng Mater Technol 46:81–98

Butuc MC, Gracio JJ, Barata da Rocha A (2006) An experimental and theoretical analysis on the application of stress-based forming limit criterion. Int J Mech Sci 48:414–429

Lee SR, Lee YK, Park CH, Yang DY (2002) A new method of preform design in hot forging by using electric field theory. Int J Mech Sci 44:773–792

Sedighi M, Tokmechi S (2008) A new approach to preform design in forging process of complex parts. J Mater Process Technol 197:314–324

Rajeshkannan A, Narayan S (2009) Strain hardening behaviour in sintered Fe–0.8%C–1.0%Si–0.8%Cu powder metallurgy preform during cold upsetting. J Eng Mfg 223:1567–1574

Ramesh B, Senthivelan T (2010) Formability characteristics of aluminium based composite—a review. Int J Eng Technol 2:1–6

Simchi A (2003) Effects of lubrication procedure on the consolidation, sintering and microstructural features of powder compacts. Mater Des 24:585–594

Narayanasamy R, Anandakrishnan V, Pandey KS (2008) Effect of carbon content on workability of powder metallurgy steels. Mater Sci Eng, A 494:337–342

Han HN, Oh KH, Lee DN (1995) Analysis of forging limit for sintered porous metals. Scr Metall Mater 32:1937–1944

Lewis RW, Khoei AR (2001) A plasticity model for metal powder forming processes. Int J Plasticity 17:1659–1692

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Narayan, S., Rajeshkannan, A. Influence of carbon content on workability behavior in the formation of sintered plain carbon steel preforms. Int J Adv Manuf Technol 64, 105–111 (2013). https://doi.org/10.1007/s00170-012-4002-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4002-x