Abstract

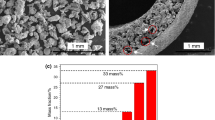

A high-temperature sodium stainless steel heat pipe was fabricated and its performance has been investigated. The working fluid was sodium and it was sealed inside a straight tube container made of stainless steel. The amount of sodium occupied approximately 20% of the total volume of the heat pipe and its weight was 65.7gram. The length of a stainless steel container is 1002mm and its outside diameter is 25.4mm. Performance tests were carried out in a room air condition under a free convective environment and the measured temperatures are presented. The start-up behavior of the heat pipe from a frozen state was investigated for various heat input values between 600W and 1205W. In steady state, axial temperature distributions of a heat pipe were measured and its heat transfer rates were estimated in the range of vapor temperature from 500°C to 630°C. It is found that there are small temperature differences in the vapor core along the axial direction of a sodium heat pipe for the high operating temperatures. But for the range of low operating temperatures there are large temperature drops along the vapor core region of a sodium heat pipe, because a small vapor pressure drop makes a large temperature drop. The transition temperature was reached more rapidly in the cases of high heat input rate for the sodium heat pipe.

Access this article

We’re sorry, something doesn't seem to be working properly.

Please try refreshing the page. If that doesn't work, please contact support so we can address the problem.

Similar content being viewed by others

Abbreviations

- A :

-

Heat transfer surface area[m2]

- C p :

-

Specific heat[J/kg · °C]

- D :

-

Diameter [m]

- g :

-

Gravitational acceleration [m/s2]

- h :

-

Heat transfer coefficient [W/m2 · °C]

- h fg :

-

Latent heat of vaporization [J/kg]

- K :

-

Permeability [m 2]

- K n :

-

Knudsen number (λ/D)

- k :

-

Thermal conductivity [W/m · °C]

- M :

-

Molecular weight [kg/kmol]

- P, p :

-

Pressure[N/m2]

- P r :

-

Reduced pressure(P/P c )

- Q,q :

-

Heat transfer rate[W]

- q″ :

-

Heat flux [W/m2]

- R :

-

Gas constant[j/kg · K]

- r :

-

Radius [m]

- s :

-

Injection/suction factor

- T :

-

Temperature [°C]

- T * :

-

Transition temperature [°C]

- Γ:

-

Specific heat ratio

- δ:

-

Liquid film thickness [m]

- λ:

-

Mean free path[m]

- μ:

-

Viscosity [N · s/m2]

- ν:

-

Dynamic viscosity [m2/s]

- ρ:

-

Density [kg/m3]

- σ:

-

Surface tension, condensing coefficient[N/m]

- ϕ:

-

Porosity of screen wick

- −:

-

Average, universal

- a :

-

Atmospheric

- b :

-

Boiling

- c :

-

Capillary, condenser, critical

- e :

-

Evaporator

- h :

-

Hydraulic

- i :

-

Inner

- nter :

-

Interphase between vapor and liquids

- l :

-

Liquid phase

- max:

-

Maximum

- n :

-

Critical nucleation

- S :

-

Surface/ sonic

- si :

-

Inside surface

- o :

-

Outer

- u :

-

Universal

- v :

-

Vapor phase, vapor section

- w :

-

Wick, wall

Reference

Carey, V. P., 1992,Liquid-vapor Phase Change Phenomena, Hemisphere Pub. Corp.

Cao, Y. and Faghri, A., 1993, “A Numerical Analysis of High-Temperature Heat Pipe Startup From the Frozen State,”Journal of Heat Transfer, Vol. 115, pp. 247–254.

Chi, S. W., 1976,Heat Pipe Theory and Practice : A Source Book, 2nd ed., Hemisphere Pub. Corp.

Collier, J. G. and Thome, J. R., 1996,Convective Boiling and Condensation, 3rd ed., Clarendon Press, Oxford, Chapter 10, pp. 436–438.

Cotter, T. P., 1965, “Theory of Heat Pipes,”Los Alamos Scientific Laboratory Report No. LA-3246-MS.

Faghri, A. Buchko, M and Cao, Y., 1991, “A Study of High Temperature Heat Pipes With Multiple Heat Sources and Sinks,”Journal of Heat Transfer, Vol. 113, pp. 1003–1009.

Faghri, A., 1995,Heat Pipe Science and Technology, Taylor & Francis.

Jang, J. H. Faghri, A. Chang, W. S. and Mahefkey, E. T., 1990, “Mathematical Modeling and Analysis of Heat Pipe Start-Up From the Frozen State,”Journal of Heat Transfer, Vol. 112, pp. 586–594.

Jang, J. H., 1996, “Performance Characteristics of Liquid Metal Heat Pipes —A Potassium Heat Pipe,”Proc. of the 3rd KSME-JSME Thermal Engineering Conference, Vol. L pp. 89–94.

Ko, Y. K. and Lee, S. H., 2000, “Manufacturing and Performance Test of a High-temperature Sodium Heat Pipe,”Proc. 5th International Symposium on Heat Transfer, pp. 680–685, Beijing.

Kutateladze, S. S., 1952, “Heat Transfer in Condensation and Boiling,” 2nd ed.,Mashgiz, Moscow, AECTranslation 3770, U.S. AEC Tech. Info. Service.

Lee, S. H., Ko, Y. K., Lee, B. I. and Lee, Y., 2000, “Manufacturing and Operation Test of a High Temperature Sodium Heat pipe,”Proc. 4th J SME-KSME Thermal Engineering conference, Vol. 1, pp. 567–572, Kobe.

Silver, R. S. and Simpson, H. C, 1961, “The Condensation of Superheated Steam,”Proc. Nat. Engng. Lab. Conf., Glasgow, Scotland.

Sukhatme, S. P. and Rohsenow, W. M., 1996, “Heat Transfer During Film Condensation of a Liquid Metal Vapor,”AS ME J. of Heat Transfer, pp. 19–28.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, B.I., Lee, S.H. Manufacturing and temperature measurements of a sodium heat pipe. KSME International Journal 15, 1533–1540 (2001). https://doi.org/10.1007/BF03185743

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF03185743