Abstract

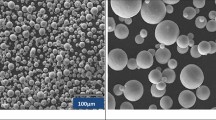

In this study, mechanical properties of bionic porous structures with diagonal-symmetrical and midline-symmetrical unit cells were studied when the porosities were same. Three typical unit cells (Diamond (DO), Rhombic Dodecahedron (RD), and Octet Truss (OT)) were selected, in which DO has diagonal-symmetrical shape, while RD and OT share midline-symmetrical structure. Based on the same porosity, corresponding models were designed, and Ti6Al4V samples were manufactured by electron beam melting. Then, using Mechanical Properties Testing (MPT) and Finite Element Analysis (FEA) methodologies, mechanical properties and transmissions of different porous structures were evaluated. Besides, composition and details before and after printing were analyzed with Energy Dispersive Spectrometer (EDS), X-ray diffraction (XRD) and Scanning Electron Microscope (SEM). MPT results showed that midline-symmetrical shape would have superior compressive performance than diagonal-symmetrical shape, but opposite trend for the torsion performance, which were in line with FEA prediction. Furthermore, effective modulus of DO, RD and OT were 2.59 GPa, 4.89 GPa, and 1.77 GPa, approximating the mechanical properties of human bones. Additionally, manufacturing defects and discrepancies between FEA and MPT were found. This study would provide great helps for unit cell selection and initial mechanical properties matching for optimum bone implants.

Similar content being viewed by others

References

Hutmacher D W. Scaffolds in tissue engineering bone and cartilage. Biomaterials, 2000, 21, 2529–2543.

Murr L E, Gaytan S M, Edwin M, Frank M, Wicker R B. Next generation orthopaedic implants by additive manufacturing using electron beam melting. International Journal of Biomaterials, 2012, 2012, 245727.

Tang D, Tare R S, Yang L Y, Williams D F, Ou K L, Oreffo R O. Biofabrication of bone tissue: Approaches, challenges and translation for bone regeneration. Biomaterials, 2016, 83, 363–382.

Beyer C, Figueroa D. Design and analysis of lattice structures for additive manufacturing. Journal of Manufacturing Science & Engineering, 2016, 138, 121014.

Yao Y Z, Xie J S, Fan S Q. A review of computer aided design for bone tissue scaffolds. Journal of Graph, 2016, 37, 367–376.

Giannitelli S M, Accoto D, Trombetta M, Rainer A. Current trends in the design of scaffolds for computer-aided tissue engineering. Acta Biomaterialia, 2014, 10, 580–594.

Albrecht L D, Sawyer S W, Soman P. Developing 3D scaffolds in the field of tissue engineering to treat complex bone defects. 3D Printing and Additive Manufacturing, 2016, 3, 106–112.

Karageorgiou V, Kaplan D. Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials, 2005, 26, 5474–5491.

Jin Q M, Takita H, Kohgo T, Atsumi K, Itoh H, Kuboki Y. Effects of geometry of hydroxyapatite as a cell substratum in BMP-induced ectopic bone formation. Journal of Biomedical Materials Research, 2000, 52, 841–851.

Kumar A, Biswas K, Basu B. Hydroxyapatite-titanium bulk composites for bone tissue engineering applications: A review. Journal of Biomedical Materials Research Part A, 2014, 103, 791–806.

Senatov F, Anisimova N, Kiselevskiy M, Kopylov A, Tcherdyntsev V, Maksimkin A. Polyhydroxybutyrate/hydroxyapatite highly porous scaffold for small bone defects replacement in the nonload-bearing parts. Journal of Bionic Engineering, 2017, 14, 648–658.

Habib F N, Nikzad M, Masood S H, Saifullah A B M. Design and development of scaffolds for tissue engineering using three-dimensional printing for bio-based applications. 3D Printing and Additive Manufacturing, 2016, 3, 119–128.

Liu Q, Li W J, Cao L, Wang J J, Qu Y M, Wang X Y, Qiu R X, Di X, Wang Z B, Liang B J. Response of MG63 osteoblast cells to surface modification of Ti-6Al-4V implant alloy by laser interference lithography. Journal of Bionic Engineering, 2017, 14, 448–458.

Zadpoor A A. Mechanics of additively manufactured biomaterials. Journal of the Mechanical Behavior of Biomedical Materials, 2017, 70, 1–6.

Shah F A, Omar O, Suska F, Snis A, Matic A, Emanuelsson L, Norlindh B, Lausmaa J, Thomsen P, Palmquist A. Long-term osseointegration of 3D printed CoCr constructs with an interconnected open-pore architecture prepared by electron beam melting. Acta Biomaterialia, 2016, 36, 296–309.

Zhao X D, Xiong D S, Wu X X. Effects of surface oxidation treatment of carbon fibers on biotribological properties of CF/PEEK materials. Journal of Bionic Engineering, 2017, 14, 640–647.

Li S J, Xu Q S, Wang Z, Hou W T, Hao Y L, Yang R, Murr L E. Influence of cell shape on mechanical properties of Ti-6Al-4V meshes fabricated by electron beam melting method. Acta Biomaterialia, 2014, 10, 4537–4547.

Snelling D, Li Q, Meisel N, Williams C B, Batra R C, Druschitz A P. Lightweight metal cellular structures fabricated via 3D printing of sand cast molds. Advanced Engineering Materials, 2015, 17, 923–932.

Zhou D, Gao Y, Lai M, Li H, Yuan B, Zhu M. Fabrication of niti shape memory alloys with graded porosity to imitate human long-bone structure. Journal of Bionic Engineering, 2015, 12, 575–582.

Basalah A, Shanjani Y, Esmaeili S, Toyserkani E. Characterizations of additive manufactured porous titanium implants. Journal of Biomedical Materials Research Part B: AppliedBiomaterials, 2012, 100, 1970–1979.

Li J, Chen D S, Luan H Q, Yan W, Fan Y B. Mechanical performance of porous implant with different unit cells. Journal of Mechanics in Medicine & Biology, 2017, 17, 1750101.

Barui S, Chatterjee S, Mandal S, Kumar A, Basu B. Microstructure and compression properties of 3D powder printed Ti-6Al-4V scaffolds with designed porosity: Experimental and computational analysis. Materials Science and Engineering: C, 2017, 70, 812–822.

Yan Y, Kang Y, Li D, Yu K, Xiao T, Wang Q Y, Deng Y W, Fang H G, Jiang D Y, Zhang Y. Microstructure, mechanical properties and corrosion behavior of porous Mg-6 wt.% Zn scaffolds for bone tissue engineering. Journal of Materials Engineering & Performance, 2018, 27, 970–984.

Pei X, Zhang B Q, Fan Y J, Zhu X D, Sun Y, Wang Q G, Zhang X D, Zhou C C. Bionic mechanical design of titanium bone tissue implants and 3D printing manufacture. Materials Letters, 2017, 208, 133–137.

Cox S C, Thornby J A, Gibbons G J. 3D printing of porous hydroxyapatite scaffolds intended for use in bone tissue engineering applications. Materials Science and Engineering: C, 2015, 47, 237–247.

Arabnejad S, Burnett J R, Pura J A, Singh B, Tanzer M, Pasini D. High-strength porous biomaterials for bone replacement: A strategy to assess the interplay between cell morphology, mechanical properties, bone ingrowth and manufacturing constraints. Acta Biomaterialia, 2016, 30, 345–356.

Wang Z H, Wang C Y, Li C, Qin Y G, Zhong L, Chen B P, Li Z Y, Liu H, Chang F, Wang J C. Analysis of factors influencing bone ingrowth into three-dimensional printed porous metal scaffolds: A review. Journal of Alloys and Compounds, 2017, 717, 271–285.

Shi J P, Yang J Q, Li Z A, Zhu L Y, Li L, Wang X S. Design and fabrication of graduated porous Ti-based alloy implants for biomedical applications. Journal of Alloys and Compounds, 2017, 728, 1043–1048.

Zheng X, Lee H, Weisgraber T H. Ultralight, ultrastiff mechanical metamaterials. Science, 2014, 344, 1373–1377.

Fu M H, Chen Y, Zhang W Z, Zheng B B. Experimental and numerical analysis of a novel three-dimensional auxetic metamaterial. Physica Status Solidi B, 2016, 253, 1565–1575.

Zadpoor A A, Hedayati R. Analytical relationships for prediction of the mechanical properties of additively manufactured porous biomaterials. Journal of Biomedical Materials Research Part A, 2016, 104, 3164–3174.

Xiao D M. Modeling of Porous Structure of Implants and Direct Manufacturing by Selective Laser Melting, PhD thesis, South China University of Technology, Guangzhou, China, 2013. (in Chinese)

Rao X, Li J, Feng X, Chu C L. Bone-like apatite growth on controllable macroporous titanium scaffolds coated with microporous titania. Journal of the Mechanical Behavior of Biomedical Materials, 2017, 77, 225–233.

Zhang X Y, Fang G, Zhou J. Additively manufactured scaffolds for bone tissue engineering and the prediction of their mechanical behavior: A review. Materials, 2017, 10, 50.

Moiduddin K. Microstructure and mechanical properties of porous titanium structures fabricated by electron beam melting for cranial implants. Proceedings of the Institution of Mechanical Engineers Part H: Journal of Engineering in Medicine, 2018, 232, 185–199.

Yu Y X, Hua S, Yang M K, Fu Z Z, Teng S S, Niu K R, Zhao Q H, Yi C Q. Fabrication and characterization of electro-spinning/3D printing bone tissue engineering scaffold. RSC Advances, 2016, 6, 110557–110565.

Mircheski I, Gradisar M. 3D finite element analysis of porous Ti-based alloy prostheses. Computer Methods in Biomechanics and Biomedical Engineering, 2016, 19, 1531–1540.

Wang L, Kang J F, Sun C N, Li D C, Cao Y, Jin Z M. Mapping porous microstructures to yield desired mechanical properties for application in 3D printed bone scaffolds and orthopaedic implants. Materials & Design, 2017, 133, 62–68.

Wang X J, Xu S Q, Zhou S W, Xu W, Leary M, Choong P, Qian M, Brandt M, Xie Y M. Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: A review. Biomaterials, 2016, 83, 127–141.

Amirkhani S, Bagheri R, Yazdi A Z. Manipulating failure mechanism of rapid prototyped scaffolds by changing nodal connectivity and geometry of the pores. Journal of Biomechanics, 2012, 45, 2866–2875.

Kumar A, Nune K C, Murr L E, Misra R D K. Biocompatibility and mechanical behavior of three-dimensional scaffolds for biomedical devices: Process-structure-property paradigm. International Materials Reviews, 2016, 61, 20–45.

Wysocki B, Idaszek J, Szlqzak K, Strzelczyk K, Brynk T, Kurzydlowski K J, Swiçszkowski W. Post processing and biological evaluation of the titanium scaffolds for bone tissue engineering. Materials, 2016, 9, 197.

Acknowledgment

This work was supported by China National Key Research and Development Plan Project (Nos. 2016YFB1101101 and 2016YFB1101102), Beijing Outstanding Young Backbone Personnel Training Project (No. 2017000026825G280), Sichuan Science and Technology Program (No. 18ZDYF1362), Fundamental Research Funds for Central Public Welfare Research Institutes (No. 118009001000160001) and National Natural Science Foundation of China (Nos. 11421202 and 11572029).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, J., Chen, D., Zhang, Y. et al. Diagonal-symmetrical and Midline-symmetrical Unit Cells with Same Porosity for Bone Implant: Mechanical Properties Evaluation. J Bionic Eng 16, 468–479 (2019). https://doi.org/10.1007/s42235-019-0038-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42235-019-0038-z