Abstract

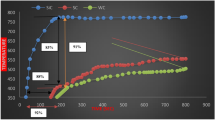

In the present work, microwave casting of Al 7039 was carried out using microwave energy at 2.45 GHz and 1400 W. A set of casts were developed through the in situ microwave casting process inside the applicator cavity applying three different solidification conditions, i.e., closed cavity cooling (cast C1), open cavity cooling (cast C2) and water-cooled cavity cooling (cast C3), whereas another cast was developed through conventional microwave casting (cast C4). Microstructure and microindentation hardness studies of the developed casts revealed that dense cast with smaller equiaxed grains could be obtained in the cast C3. Presence of the intermetallic phases, MgZn2, Mg2Si, Al3Fe and Al8Fe2Si, was observed in the in situ casts, whereas the cast C4 contains intermetallic phases: MgZn2, Mg2Si, Al2Cu, Al2CuMg and Al7Cu2Fe. It was found that the grain structure and major attributes of the intermetallic precipitates (size, shape and distribution) in the casts significantly depend on the solidification conditions. Average microindentation hardness of the cast C4 was found to be 191 ± 32 HV which is higher than other casts. The study showed that microindentation characteristics of the casts depend more on attributes of the precipitated intermetallic phases during solidification than the grain size.

Similar content being viewed by others

References

E.J. Lavernia, J.D. Ayers, T.S. Srivatsan, Int. Mater. Rev. 37, 1 (1992)

M.F. Ibrahim, G.H. Garza-Elizondo, A.M. Samuel et al., Int. J. Metalcast. (2016). doi:10.1007/s40962-016-0038-2

E. Druschitz, R. D. Foley, J. A. Griffin, Transactions of the American Foundry Society, in 117th Annual Metalcasting Congress, Paper No. 13-1568, P231-241, (AFS Online Library 20130163)

P. Ashtari, G. Birsan, A. Khalaf et al., Int. J. Metalcast. (2011). doi:10.1007/BF03355471

M.D. David, R.D. Foley, J.A. Griffin et al., Int. J. Metalcast. (2016). doi:10.1007/s40962-015-0006-2

H. Akhyar, Husaini. Int. J. Metalcast. (2016). doi:10.1007/s40962-016-0024-8

J. Zhao, C. Xu, G. Dai, S. Wu, J. Han, Mater. Lett. 173, 22 (2016)

X. Su, G.M. Xu, D.H. Jiang, Rare Met. 34, 546 (2015)

Z. Shao, Q. Le, Z. Zhang, J. Cui, Mater. Des. 32, 4216 (2011)

E. Acer, E. Çadırlı, H. Erol, M. Gündüz, Metall. Mater. Trans. A 47, 3040 (2016)

R.R. Mishra, A.K. Sharma, Crit. Rev. Solid State Mater. Sci. 41, 217 (2016)

C. Leonelli, P. Veronesi, L. Denti, A. Gatto, L. Iuliano, J. Mater. Process. Technol. 205, 489 (2008)

K. Rajkumar, S. Aravindan, J. Mater. Process. Technol. 209, 5601 (2009)

M. Gupta, W.L.E. Wong, Scr. Mater. 52, 479 (2005)

A. Mondal, D. Agrawal, A. Upadhyaya, J. Microw. Power Electromagn. Energy. 44, 28 (2010)

M.M. Mahmoud, G. Link, M. Thumm, J. Alloys Compd. 627, 231 (2015)

R. Roy, D. Agrawal, J. Cheng, S. Gedevanishvili, Nature 399, 668 (1999)

D. Demirskyi, D. Agrawal, A. Ragulya, J. Alloys Compd. 509, 1790 (2011)

M.S. Srinath, A.K. Sharma, P. Kumar, Mater. Des. 32, 2685 (2011)

A. Bansal, A.K. Sharma, P. Kumar, S. Das, Mater. Charact. 91, 34 (2014)

S. Zafar, A.K. Sharma, Mater. Charact. 96, 241 (2014)

D. Gupta, A.K. Sharma, Surf. Coat. Technol. 205, 5147 (2011)

D. Agrawal, Mater. Res. Innov. 14, 3 (2010)

S. Chandrasekaran, T. Basak, S. Ramanathan, J. Mater. Process. Technol. 211, 482 (2011)

A.F. Moore, D.E. Schechter, M.S. Morrow, U.S. Patent No. 7,011,136. Washington, DC: U.S. Patent and Trademark Office, 2006

E.B. Ripley, J.A. Oberhaus, Ind. Heat. 72, 61 (2005)

R.R. Mishra, A.K. Sharma, Mater. Des. 112, 97 (2016)

R.R. Mishra, A.K. Sharma, Appl. Therm. Eng. 111, 660 (2017)

R.R. Mishra, A.K. Sharma, Mater. Sci. Eng., A 688, 532 (2017)

S. Singh, D. Gupta, V. Jain, Mater. Des. 111, 51 (2016)

R.R. Mishra, A.K. Sharma, Compos. Part A: Appl. Sci. Manuf. 81, 78 (2016)

R.R. Mishra, A.K. Sharma, Mater. Des. 131, 428 (2017)

J.R. Davis, in Aluminum and Aluminum Alloys, ed. by J.R. Davis (ASM international, Russell Township, 1993), p. 93

D.G. Eskin, L. Katgerman, Prog. Mater Sci. 49, 629 (2004)

W. Kasprzak, M. Sahoo, J. Sokolowski, H. Yamagata, H. Kurita, Int. J. Metalcast. 3, 55 (2009)

J.T. Liu, Y.A. Zhang, X.W. Li, Z.H. Li, B.Q. Xiong, J.S. Zhang, Rare Met. 35, 380 (2016)

R. Orozco, J. Genesca, J. Juarez-Islas, J. Mater. Engg. Perform. 16, 229 (2007)

S.H. Wang, L.G. Meng, S.J. Yang, C.F. Fang, H.A.O. Hai, S.L. Dai, X.G. Zhang, T. Nonferr, Metal Soc. 21, 1449 (2011)

L. Litynska-Dobrzynska, J. Dutkiewicz, W. Maziarz, A. Góral, Mater. Trans. 52, 309 (2011)

C.H. Fan, Z.H. Chen, W.Q. He, J.H. Chen, D. Chen, J. Alloys compd. 504, L42 (2010)

N.A. Belov, D.G. Eskin, A.A. Aksenov, Multicomponent Phase Diagrams: Applications for Commercial Aluminum Alloys, 1st edn. (Elsevier, London, 2005), pp. 1–6

K. Liu, X. Cao, X.G. Chen, Metall. Mater. Trans. A 42, 2004 (2011)

A. Deschamps, Y. Brechet, F. Livet, Mater. Sci. Technol. 15, 993 (1999)

E.O. Hall, Proc. Phys. Soc. Lond., Sect. B 64, 747 (1951)

D. Srinivasan, R. Corderman, P.R. Subramanian, Mater. Sci. Eng., A 416, 211 (2006)

J.K. Park, A.J. Ardell, Metall. Trans. A 14, 1957 (1983)

U.A. Curle, L.A. Cornish, G. Govender, Mater. Des. 99, 211 (2016)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mishra, R.R., Sharma, A.K. Effect of Solidification Environment on Microstructure and Indentation Hardness of Al–Zn–Mg Alloy Casts Developed Using Microwave Heating. Inter Metalcast 12, 370–382 (2018). https://doi.org/10.1007/s40962-017-0176-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-017-0176-1