Abstract

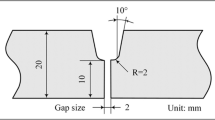

Laser beam welding may be used in the place of the traditional riveting process for the welding of the stringers to the skin in aircrafts. This work intends to investigate the mechanical behavior of laser-welded aluminum AA6013, subjected to post-welding heating treatments (PWHT). A fiber laser with an average power of 1.5 kW was used to weld two 1.6-mm-thick sheets in T-joint configuration. After welding, the samples were separated in three groups: the first just welded, the second subjected to a PWHT during 4 h at 190 °C and the third during 2 h at 205 °C. Hoop tensile tests showed that the thermal treatment at 190 °C for 4 h increased the tensile strength in 76 MPa, but the strain had decreased 4 %; the thermal treatment at 205 °C for 2 h increased maximum strength in 65 MPa, with a decrease in strain of 5 %. In T-pull tensile tests, the tensile properties of as-welded and PWHT samples remained the same. Standard S–N curve showed that the welding reduce the number of cycles to failure for the tested stairs. PWHT did not affect fatigue properties.

Similar content being viewed by others

References

Schubert E, Klassen M, Zerner I, Walz C, Sepold G (2008) Light-weight structures produced by laser beam joining for future applications in automobile and aerospace industry. J Mater Process Technol 115:2–8

Badini C, Pavese M, Fino P, Biamino S (2009) Laser beam welding of dissimilar aluminium alloys of 2000 and 7000 series: effect of postwelding thermal treatments on T joint strength. Sci Technol Weld Join 14:484–492

Frank P (2007) Laser Beam Welding en Skin-Stringer Joints: Current and New and Al-Alloys. In: Proceedings of the European Workshop on Short Distance Welding Concepts for Airframes, CD, Hamburg, Germany, Presentation number 17

Braun R (2006) Nd:YAG laser butt welding of AA6013 using silicon and magnesium containing filler powders. Mater Sci Eng A 426:250–262

Rötzer I (2005) Laser beam welding makes aircraft lighter. Fraunhoffer Mag 1:36–37

Dittrich D, Standfuss JL, Brenner B, Beyer E (2011) Laser beam welding of hard to weld al alloys for regional aircraft fuselage design—first results. Phys Procedia 12:113–122

Frabrègue D, Deschamps A, Suèry M (2009) Influence of the silicon content on the mechanical properties of AA6xxx laser welds. Mater Sci Eng A 506:157–164

Squillace A, Prisco U (2009) Influence of filler material on micro- and macro-mechanical behavior of laser-beam-welded T-joint for aerospace applications. Mater Des Appl 223:103–115

Beneder J, Prillhofer R, Enser J, Schulz P, Melzer C (2011) Study of the artificial aging kinetics of different AA6013—T4 heat treatment conditions. In: Proceedings of the 140th annual meeting of TMS - The minerals, metals and materials society, vol 2. San Diego, USA

Kannatey-Asibu E (2009) Principles of laser materials processing. Wiley, New Jersey, p 819

Oliveira AC (2011) Welding of the aluminum structural aeronautical using a fiber laser of the high power (In Portuguese), Ph.D. Thesis, Instituto Tecnológico de Aeronáutica, S.P., Brazil, 152p

Metals Handbook (1973) Heat Treating, 8th edn. Vol. 4: American Society for Metals, Materials Park, p 2173

Prisco A, Acerra F, Squillace A, Giorleo G, Pirozzi C, Prisco U, Bellucci F (2008) LBW of similar and dissimilar skin-stringer joints part I: process optimization and mechanical. Adv Mater Res 38:306–319

Porter DA, Easterling K (1992) Phase transformations in metals and alloys. Chapman & Hall, New York, p 440

Kou S (2003) Solidification and liquation cracking issues in welding. J Miner Metals Mater Soc 55:37–42

Rappaz M, Drezet JM, Gremaud M (1999) A new hot tearing criterion metal. Metall Mater Transact A 30A:449–455

Barbosa C, Rebello JMA, Dille Acselrad J, Delplancke L (2002) Identification of precipitates in 6013 aluminum alloy (Al–Mg–Si–Cu). Int J Mater Res 93:208–211

Acknowledgments

The authors thank the financial support of the following agencies: FAPESP, CNPq, CAPES and FINEP.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Alexandre Mendes Abrao.

Rights and permissions

About this article

Cite this article

de Siqueira, R.H.M., de Oliveira, A.C., Riva, R. et al. Mechanical and microstructural characterization of laser-welded joints of 6013-T4 aluminum alloy. J Braz. Soc. Mech. Sci. Eng. 37, 133–140 (2015). https://doi.org/10.1007/s40430-014-0175-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40430-014-0175-6