Abstract

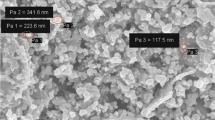

This study aimed to investigate the effect of nanoparticles on the strength of single-lap nanocomposite joints. Three different types of specimens were studied, each of which contained 1 wt% of carbon nanotube in the adhesive. The adherends included three different percentages of nanoclays, namely 0, 5 and 7 wt%. The material used here was glass fibers/epoxy, with epoxy as the matrix. After fabrication of the laminates, they were stuck together by epoxy resin containing 1 wt% of carbon nanotube. Different tests were also conducted to analyze the specimens. These tests included X-ray diffraction (XRD), scanning electron microscope (SEM) and tensile test. In the XRD test, the presence of glass fiber, epoxy resin and nanoclays was verified and in the SEM test, the distribution of nanoclays into the laminates was investigated and finally the strength of the joints with different nanoparticles was examined by tensile test. In addition, a finite element (FE) analysis was also incorporated and the results of this method were verified by the experimental results. To perform the FE analysis, Young’s modulus of the laminates and the adhesive were both required. Therefore, a tensile test was conducted to obtain the Young’s modulus of the adherends and the elastic modulus of adhesive was obtained from the data existing in the literature. Finally, the results from FE analysis and the experimental tests were compared with each other and a good agreement was observed. It was finally concluded that the specimen comprised of 5 wt% nanoclays had the best performance among the three.

Similar content being viewed by others

References

Kim KS, Yoo JS, Yi YM, Kim CG (2006) Failure mode and strength of uni-directional composite single-lap bonded joints with different bonding methods. Compos Struct 72:477–485

Beylergil B, Cunedioglu Y, Aktas A (2011) Experimental and numerical analysis of single lap composite joints with inter-adherend fibers. Compos Part B 42:1885–1896

Li R, Huong N, Crosky A, Mouritz AP, Kelly D, Chang P (2009) Improving bearing performance of composite bolted joints using z-pins. Compos Sci Technol 69:883–889

Matsuzaki R, Shibata M, Todoroki A (2008) Reinforcing an aluminum/GFRP co-cured single lap joint using inter-adherend fiber. Compos Part A 39:786–795

Matsuzaki R, Shibata M, Todoroki A (2008) Improving performance of GFRP/aluminum single lap joints using bolted/co-cured hybrid method. Compos Part A 39:154–163

Park YB, Song MG, Kim JJ, Kweon JH, Choi JH (2010) Strength of carbon/epoxy composite single-lap bonded joints in various environmental conditions. Compos Struct 92:2173–2180

Ferreira JAM, Reis PN, Costa JDM, Richardson MOW (2002) Fatigue behaviour of composite adhesive lap joints. Compos Sci Technol 62:1373–1379

Reis PNB, Ferreira JM, Richardson MOW (2012) Effect of the surface preparation on PP reinforced glass fibre adhesive lap joints strength. J Thermoplast Compos Mater 25:3–13

Parker BM (1986) Some effects of moisture on adhesive-bonded CFRP–CFRP joints. Compos Struct 6:123–139

Parker BM (1990) The strength of bonded carbon fibre composite joints exposed to high humidity. Int J Adhes Adhes 10:187–191

Ashcroft IA, Hughes DJ, Shaw SJ (2000) Adhesive bonding of fiber reinforced polymer composite materials. Assem Autom 20:150–161

Zhang Y, Vassilopoulos AP, Keller T (2009) Environmental effects on fatigue behavior of adhesively-bonded pultruded structural joints. Compos Sci Technol 69:1022–1028

Srivastava VK (2011) Effect of carbon nanotubes on the strength of adhesive lap joints of C/C and C/C–SiC ceramic fibre composites. Int J Adhes Adhes 31:486–489

Tsai MY, Morton J, Matthews FL (1995) Experimental and numerical studies of a laminated composite single-lap ddhesive joint. J Compos Mater 29:1254–1275

Lang TP, Mallick PK (1998) Effect of spew geometry on stresses in single-lap adhesive joints. Int J Adhes Adhes 18:167–177

Chang P, Mouritz AP, Cox BN (2008) Elevated temperature properties of pinned composite lap joints. J Compos Mater 42:741–769

Chang P, Mouritz AP, Cox BN (2006) Properties and failure mechanisms of pinned composite lap joints in monotonic and cyclic tension. Compos Sci Technol 66:2163–2176

Kairouz KC, Matthews FL (1993) Strength and failure modes of bonded single-lap joints between cross-ply adherends. Composites 24:475–484

Vinson JR, Sierakowski RL (2002) The behavior of structures composed of composite materials. KLUWER Academic Publishers, The Netherlands

Gent AN, Lin CW (1990) Model studies of the effect of surface roughness and mechanical interlocking on adhesion. J Adhes 32:113–125

Yao Q (2000) Modeling and characterization of interfacial adhesion and fracture. Thesis, Georgia Institute of Technology

Kim WS, Yun IH, Lee JJ, Jung HT (2010) Evaluation of mechanical interlock effect on adhesion strength of polymer–metal interfaces using micro-patterned surface topography. Int J Adhes Adhes 30:408–417

Park SJ, Jin JS, Lee JR (2000) Influence of silane coupling agents on the surface energetics of glass fibers and mechanical interfacial properties of glass fiber-reinforced composites. J Adhes Sci Technol 14:1677–1689

Feller JF, Grohens Y (2004) Coupling ability of silane grafted poly(propene) at glass fibers/poly(propene) interface. Compos Part A 35:1–10

Kinloch AJ (1980) The science of adhesion, part I—surface and interfacial aspects. J Mater Sci 15:2141–2166

Luo Y, Zhao Y, Cai J, Duan Y, Du S (2012) Effect of amino-functionalization on the interfacial adhesion of multi-walled carbon nanotubes/epoxy nanocomposites. Mater Des 33:405–412

Dorigato A, Morandi S, Pegoretti A (2012) Effect of nanoclay addition on the fiber/matrix adhesion in epoxy/glass composites. J Compos Mater 46:1439–1451

Horn RG, Smith DT (1992) Contact electrification and adhesion between dissimilar materials. Science 256:362–364

Dickinson JT, Jensen LC, Lee S, Scudiero L, Langford SC (1994) Fracto-emission and electrical transients due to interfacial failure. J Adhes Sci Technol 8:1285–1309

Voyutskii SS, Vakula VL (1963) The role of diffusion phenomena in polymer-to-polymer adhesion. J Appl Polym Sci 7:475–491

Niu S, Cai S, Liu T, Zhao H, Wang X, Ren M, Huang K, Wu X (2015) 45S5 bioactive glass-ceramic coated magnesium alloy with strong interfacial bonding strength by superplasticity diffusion bonding. Mater Lett 141:96–99

Gude MR, Prolongo SG, Rio TG, Urena A (2011) Mode-I adhesive fracture energy of carbon fibre composite joints with nanoreinforced epoxy adhesives. Int J Adhes Adhes 31:695–703

Mylavarapu P, Woldesenbet E (2010) Effect of nanoclay incorporation on the impact properties of adhesively bonded composite structures. J Adhes Sci Technol 24:389–405

Khalili SMR, Tavakolian M, Sarabi A (2010) Mechanical properties of nanoclay reinforced epoxy adhesive bonded joints made with composite materials. J Adhes Sci Technol 24:1917–1928

Fereidoon A, Kordani N, Rostamiyan Y, Ganji DD, Ahangari MG (2010) Effect of carbon nanotube on adhesion strength of E-glass/epoxy composite and alloy aluminuim surface. World Appl Sci J 9:204–210

Montazeri A, Javadpour J, Khavandi A, Tcharkhtchi A, Mohajeri A (2010) Mechanical properties of multi-walled carbon nanotube/epoxy composites. Mater Des 31:4202–4208

Nguyen QT, Baird DG (2007) An improved technique for exfoliating and dispersing nanoclay particles into polymer matrices using supercritical carbon dioxide. Polymer 48:6923–6933

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bagheri, M.R., Sadough Vanini, S.A., Kordani, N. et al. The effect of nanoparticles in single-lap composite joints studied by experimental and numerical analyses. Iran Polym J 24, 629–640 (2015). https://doi.org/10.1007/s13726-015-0351-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-015-0351-2