Abstract

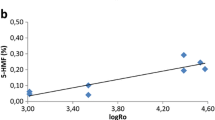

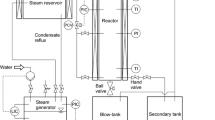

The importance of flow conditions during scale-up of high-solid enzymatic hydrolysis of steam-pretreated spruce was demonstrated by comparing hydrolysis rates between laboratory (2 L) and demonstration (4 m3) scale. A positive effect of increased agitation speed on the rate of enzymatic hydrolysis was found regardless of scale. Importantly, the hydrolysis rate was higher at the larger scale when compared at similar specific power inputs. Changes in the rheological properties of the pretreated material during the hydrolysis were followed by off-line measurements of apparent viscosity. This information was used to estimate the flow conditions in the reactors, i.e., average Reynolds numbers, which together with measured mixing power consumptions enabled a more detailed comparison between the scales. The hydrolysis yields correlated better with average Reynolds numbers than specific power input over the different scales. This indicates that mass transport limitations, caused by insufficient bulk flow, likely play a decisive role in determining the rate of enzymatic hydrolysis.

Similar content being viewed by others

References

Balan V, Chiaramonti D, Kumar S (2013) Review of US and EU initiatives toward development, demonstration, and commercialization of lignocellulosic biofuels. Biofuels Bioprod Biorefin 7:732–759

Janssen R, Turhollow AF, Rutz D, Mergner R (2013) Production facilities for second-generation biofuels in the USA and the EU—current status and future perspectives. Biofuels Bioprod Biorefin 7:647–665

Galbe M, Sassner P, Wingren A, Zacchi G (2007) Process engineering economics of bioethanol production. In: Olsson L (ed) Biofuels. Springer, Berlin, pp 303–327

Humbird D, Mohagheghi A, Dowe N, Schell DJ (2010) Economic impact of total solids loading on enzymatic hydrolysis of dilute acid pretreated corn stover. Biotechnol Prog 26:1245–1251

Macrelli S, Mogensen J, Zacchi G (2012) Techno-economic evaluation of 2nd generation bioethanol production from sugar cane bagasse and leaves integrated with the sugar-based ethanol process. Biotechnol Biofuels 5:22

Wingren A, Galbe M, Zacchi G (2003) Techno-economic evaluation of producing ethanol from softwood: comparison of SSF and SHF and identification of bottlenecks. Biotechnol Prog 19:1109–1117

Knutsen JS, Liberatore MW (2009) Rheology of high-solids biomass slurries for biorefinery applications. J Rheol 53:877–892

Pimenova NV, Hanley TR (2004) Effect of corn stover concentration on rheological characteristics. Appl Biochem Biotechnol 114:347–360

Viamajala S, McMillan JD, Schell DJ, Elander RT (2009) Rheology of corn stover slurries at high solids concentrations—effects of saccharification and particle size. Bioresour Technol 100:925–934

Wiman M, Palmqvist B, Tornberg E, Lidén G (2011) Rheological characterization of dilute acid pretreated softwood. Biotechnol Bioeng 108:1031–1041

Roche CM, Dibble CJ, Knutsen JS, Stickel JJ, Liberatore MW (2009) Particle concentration and yield stress of biomass slurries during enzymatic hydrolysis at high-solids loadings. Biotechnol Bioeng 104:290–300

Viamajala S, Donohoe BS, Decker SR, Vinzant TB, Selig MJ, Himmel ME, Tucker MP (2010) Heat and mass transport in processing of lignocellulosic biomass for fuels and chemicals. In: Singh OV, Harvey SP (eds) Sustainable biotechnology. Springer, Dordrecht, pp 1–18

Dasari RK, Dunaway K, Berson RE (2009) A scraped surface bioreactor for enzymatic saccharification of pretreated corn stover slurries. Energy Fuels 23:492–497

Palmqvist B, Wiman M, Lidén G (2011) Effect of mixing on enzymatic hydrolysis of steam-pretreated spruce: a quantitative analysis of conversion and power consumption. Biotechnol Biofuels 4:10

Roche CM, Dibble CJ, Stickel JJ (2009) Laboratory-scale method for enzymatic saccharification of lignocellulosic biomass at high-solids loadings. Biotechnol Biofuels 2:28

Tengborg C, Galbe M, Zacchi G (2001) Influence of enzyme loading and physical parameters on the enzymatic hydrolysis of steam-pretreated softwood. Biotechnol Prog 17:110–117

Zhang J, Chu D, Huang J, Yu Z, Dai G, Bao J (2010) Simultaneous saccharification and ethanol fermentation at high corn stover solids loading in a helical stirring bioreactor. Biotechnol Bioeng 105:718–728

Palmqvist B, Lidén G (2012) Torque measurements reveal large process differences between materials during high solid enzymatic hydrolysis of pretreated lignocellulose. Biotechnol Biofuels 5:57

Kadić A, Palmqvist B, Lidén G (2014) Effects of agitation on particle-size distribution and enzymatic hydrolysis of pretreated spruce and giant reed. Biotechnol Biofuels 7:77

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. Report no. TP-510-42618, National Renewable Energy Laboratory, Golden

Barnes HA (1995) A review of the slip (wall depletion) of polymer solutions, emulsions and particle suspensions in viscometers: its cause, character, and cure. J Non-Newtonian Fluid Mech 56:221–251

Barnes HA, Nguyen QD (2001) Rotating vane rheometry – a review. J Non-Newtonian Fluid Mech 98:1–14

Buscall R, McGowan JI, Morton-Jones AJ (1993) The rheology of concentrated dispersions of weakly attracting colloidal particles with and without wall slip. J Rheol 37:621–641

Stickel JJ, Knutsen JS, Liberatore MW, Luu W, Bousfield DW, Klingenberg DJ, Scott CT, Root TW, Ehrhardt MR, Monz TO (2009) Rheology measurements of a biomass slurry: an inter-laboratory study. Rheol Acta 48:1005–1015

Metzner AB, Otto RE (1957) Agitation of non-newtonian fluids. AlChE J 3:3–10

Nagata S, Nishikawa M, Tada H, Gotoh S (1971) Power consumption of mixing impellers in pseudoplastic liquids. J Chem Eng Jpn 4:72–76

Zhu Y, Malten M, Torry-Smith M, McMillan JD, Stickel JJ (2011) Calculating sugar yields in high solids hydrolysis of biomass. Bioresour Technol 102:2897–2903

Zhang J, Bao J (2012) A modified method for calculating practical ethanol yield at high lignocellulosic solids content and high ethanol titer. Bioresour Technol 116:74–79

Hoyer K, Galbe M, Zacchi G (2009) Production of fuel ethanol from softwood by simultaneous saccharification and fermentation at high dry matter content. J Chem Technol Biotechnol 84:570–577

Dasari RK, Berson RE (2007) The effect of particle size on hydrolysis reaction rates and rheological properties in cellulosic slurries. Appl Biochem Biotechnol 137–140:289–299

Rosgaard L, Andric P, Dam-Johansen K, Pedersen S, Meyer AS (2007) Effects of substrate loading on enzymatic hydrolysis and viscosity of pretreated barley straw. Appl Biochem Biotechnol 143:27–40

Amanullah A, Hjorth SA, Nienow AW (1997) Cavern sizes generated in highly shear thinning viscous fluids by SCABA 3SHP1 impellers. Food Bioprod Process 75:232–238

Solomon J, Elson TP, Nienow AW, Pace GW (1981) Cavern sizes in agitated fluids with a yield stress. Chem Eng Commun 11:143–164

Elson TP, Cheesman DJ, Nienow AW (1986) X-ray studies of cavern sizes and mixing performance with fluids possessing a yield stress. Chem Eng Sci 41:2555–2562

Funding

This study was funded by the Swedish Energy Agency (grant numbers 37896–1 and 35353–1).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Palmqvist, B., Kadić, A., Hägglund, K. et al. Scale-up of high-solid enzymatic hydrolysis of steam-pretreated softwood: the effects of reactor flow conditions. Biomass Conv. Bioref. 6, 173–180 (2016). https://doi.org/10.1007/s13399-015-0177-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-015-0177-3