Abstract

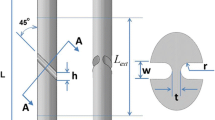

Average true flow stress-logarithmic true strain curves can be usually obtained from a tensile test. After the onset of necking, the average true flow stress-logarithmic true strain data from a tensile specimen with round cross section should be modified by using the correction formula proposed by Bridgman. But there have been no firmly established correction formulae applicable to a specimen with rectangular cross section. In this paper, a new easy-to-use formula is presented based on parametric finite element simulations. The new formula requires only incremental plastic strain and hardening exponents of the material, which are simply presented from a tensile test. The newly proposed formula is verified with experimental data for high strength steel DH32 used in the shipbuilding and offshore industry and is proved to be effective during the diffuse necking regime.

Similar content being viewed by others

References

P. W. Bridgman, Studies in Large Plastic Flow and Fracture, McGraw-Hill, New York, (1952).

J. Aronofsky, Evaluation of stress distribution in the symmetrical neck of flat tensile bars, J. Appl. Mech. (1951) 75–84.

K. S. Zhang, M. Hauge, J. Odegard and C. Thaulow, Determining material true stress-strain curve from tensile specimens with rectangular cross section, Int. J. Solids Struct. 36 (1999) 3497–3516.

Y. Ling, Uniaxial true stress-strain after necking, AMP J. Technology 5 (1996) 37–48.

I. Scheider, W. Brocks and A. Cornec, Procedure for the determination of true stress-strain curves from tensile tests with rectangular cross-section specimens, J. Eng. Mater. Tech. 126 (2004) 70–76.

S. Kalpakjian and S. R. Schmid, Manufacturing Processes for Engineering Materials, Addison Wesley Publishing Co., (2001).

K. S. Zhang and Z. H. Li, Numerical analysis of the stress-strain curve and fracture initiation for ductile material, Engng. Fracture Mech. 49 (1994) 235–241.

G. LeRoy, J. Embury, G. Edwards and M. F. Ashby, A model of ductile fracture based on the nucleation and growth of voids, Acta Metallurgica 29 (1981) 1509–1522.

ASTM E8, Standard Test Methods for Tension Testing of Metallic Materials, (2004).

JIS Z 2201, Test Pieces for Tensile Test for Metallic Materials, (1998).

KS B 0801, Test Pieces for Tensile Test for Metallic Materials, (1981).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choung, J.M., Cho, S.R. Study on true stress correction from tensile tests. J Mech Sci Technol 22, 1039–1051 (2008). https://doi.org/10.1007/s12206-008-0302-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-008-0302-3