Abstract

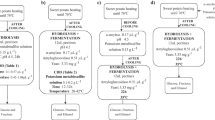

Due to its merits of drought tolerance and high yield, sweet potatoes are widely considered as a potential alterative feedstock for bioethanol production. Very high gravity (VHG) technology is an effective strategy for improving the efficiency of ethanol fermentation from starch materials. However, this technology has rarely been applied to sweet potatoes because of the high viscosity of their liquid mash. To overcome this problem, cellulase was added to reduce the high viscosity, and the optimal dosage and treatment time were 8 U/g (sweet potato powder) and 1 h, respectively. After pretreatment by cellulase, the viscosity of the VHG sweet potato mash (containing 284.2 g/L of carbohydrates) was reduced by 81%. After liquefaction and simultaneous saccharification and fermentation (SSF), the final ethanol concentration reached 15.5% (v/v), and the total sugar conversion and ethanol yields were 96.5% and 87.8%, respectively.

Similar content being viewed by others

References

Lynd L R. Overview and evaluation of fuel ethanol from cellulosic biomass: technology, economics, the environment, and policy. Annual Review of Energy and the Environment, 1996, 21(1): 403–465

Liu S Y, Lin C Y. Development and perspective of promising energy plants for bioethanol production in Taiwan. Renewable Energy, 2009, 34(8): 1902–1907

Worley J W, Vaughan D H, Cundiff J S. Energy analysis of ethanol production from sweet sorghum. Bioresource Technology, 1992, 40(3): 263–273

Lu G Q, Huang H H, Zhang D P. Application of near-infrared spectroscopy to predict sweetpotato starch thermal properties and noodle quality. Journal of Zhejiang University, Science B, 2006, 7(6): 475–481

Yang J Q. Chinese Patent, 1727491, 2006-20-01

Gong D C, Gong M Z, Li D Y. Chinese Patent, 1966696, 2007-05-23

Zhang L A, Chen Q A, Jin Y L, Xue H L, Guan J F, Wang Z Y, Zhao H. Energy-saving direct ethanol production from viscosity reduction mash of sweet potato at very high gravity (VHG). Fuel Processing Technology, 2010, 91(12): 1845–1850

Bayrock D P, Michael I W. Application of multistage continuous fermentation for production of fuel alcohol by very-high-gravity fermentation technology. Journal of Industrial Microbiology & Biotechnology, 2001, 27(2): 87–93

Thomas K C, Hynes S H, Jones A M, Ingledew WM. Production of fuel alcohol from wheat by VHG technology. Applied Biochemistry and Biotechnology, 1993, 43(3): 211–226

Thomas K C, Hynes S H, Ingledew W M. Practical and theoretical considerations in the production of high concentrations of alcohol by fermentation. Process Biochemistry, 1996, 31(4): 321–331

Dragone G, Mussatto S I, Silva J B A E. High gravity brewing by continuous process using immobilised yeast: effect of wort original gravity on fermentation performance. J I Brewing, 2007, 113: 391–398

Pereira F B, Guimarães P M R, Teixeira J A, Domingues L. Optimization of low-cost medium for very high gravity ethanol fermentations by Saccharomyces cerevisiae using statistical experimental designs. Bioresource Technology, 2010, 101(20): 7856–7863

Laopaiboon L, Nuanpeng S, Srinophakun P, Klanrit P, Laopaiboon P. Ethanol production from sweet sorghum juice using very high gravity technology: effects of carbon and nitrogen supplementations. Bioresource Technology, 2009, 100(18): 4176–4182

Reddy L V. Improvement of ethanol production in very high gravity (VHG) fermentation by black gram (Vigna mungo) flour supplementation. New Biotechnology, 2009, 25: S229–S230

Dragone G, Mussatto S I, Silva J B A. Use of concentrated worts for high gravity brewing by continuous process: new tendencies for the productivity increase. Ciênc Tecnol Aliment, 2007, 27: 37–40

Shen Y, Ge X M, Bai F W. Application of oscillation for efficiency improvement of continuous ethanol fermentation with Saccharomyces cerevisiae under very-high-gravity conditions. Applied Microbiology and Biotechnology, 2010, 86(1): 103–108

Pradeep P, Goud G K, Reddy O V S. Optimization of very high gravity (VHG) finger millet (ragi) medium for ethanolic fermentation by yeast. Chiang Mai J Sci, 2010, 37: 116–123

Ingledew W M, Thomas K C, Hynes S H, McLeod J G. Viscosity concerns with rye mashes used for ethanol production. Cereal Chemistry, 1999, 76(3): 459–464

Wang D, Bean S, McLaren J, Seib P, Madl R, Tuinstra M, Shi Y, Lenz M, Wu X, Zhao R. Grain sorghum is a viable feedstock for ethanol production. Journal of Industrial Microbiology & Biotechnology, 2008, 35(5): 313–320

Che L M, Wang L J, Li D, Bhandari B, Özkan N, Chen X D, Mao Z H. Starch pastes thinning during high-pressure homogenization. Carbohydrate Polymers, 2009, 75(1): 32–38

Oxenboll Sørensen S, Pauly M, Bush M, Skjøt M, McCann M C, Borkhardt B, Ulvskov P. Pectin engineering: modification of potato pectin by in vivo expression of an endo-1,4-beta-D-galactanase. Proceedings of the National Academy of Sciences of the United States of America, 2000, 97(13): 7639–7644

Sriroth K, Chollakup R, Chotineeranat S, Piyachomkwan K, Oates C G. Processing of cassava waste for improved biomass utilization. Bioresource Technology, 2000, 71(1): 63–69

Zhong C, Lau M W, Balan V, Dale B E, Yuan Y J. Optimization of enzymatic hydrolysis and ethanol fermentation from AFEX-treated rice straw. Applied Microbiology and Biotechnology, 2009, 84(4): 667–676

Nitayavardhana S, Rakshit S K, Grewell D, van Leeuwen J H, Khanal S K. Ultrasound pretreatment of cassava chip slurry to enhance sugar release for subsequent ethanol production. Biotechnology and Bioengineering, 2008, 101(3): 487–496

Phisalaphong M, Srirattana N, Tanthapanichakoon W. Mathematical modeling to investigate temperature effect on kinetic parameters of ethanol fermentation. Biochemical Engineering Journal, 2006, 28(1): 36–43

Banat I M, Nigam P, Singh D, Marchant R, McHale A P. Ethanol production at elevated temperatures and alcohol concentrations: Part I — Yeasts in general. World Journal of Microbiology and Biotechnology, 1998, 14(6): 809–821

McMillan J D, Newman M M, Templeton D W, Mohagheghi A. Simultaneous saccharification and cofermentation of dilute-acid pretreated yellow poplar hardwood to ethanol using xylosefermenting Zymomonas mobilis. Applied Biochemistry and Biotechnology, 1999, 79(1–3): 649–665

Liu C L, Zhao Z H. Study on the fermentation technology of high-efficiency environment-protection and energy-saving alcohol. Liquor Making Sci Technol, 2007, 3: 75–77 (in Chinese)

Srichuwong S, Fujiwara M, Wang X H, Seyama T, Shiroma R, Arakane M, Mukojima N, Tokuyasu K. Simultaneous saccharification and fermentation (SSF) of very high gravity (VHG) potato mash for the production of ethanol. Biomass and Bioenergy, 2009, 33(5): 890–898

Choi GW, Moon S K, Kang HW, Min J, Chung BW. Simultaneous saccharification and fermentation of sludge-containing cassava mash for batch and repeated batch production of bioethanol by Saccharomyces cerevisiae CHFY0321. Journal of Chemical Technology and Biotechnology, 2009, 84(4): 547–553

Choi G W, Kang H W, Kim Y R, Chung B W. Ethanol production by Zymomonas mobilis CHZ2501 from industrial starch feedstocks. Biotechnology and Bioprocess Engineering, 2008, 13(6): 765–771

Wu S H, Jiang C D, Yi Y, Huang C J, Xu Y F, Tong Z F. Optimize conditions of liquefaction for producing manioc alcohol by high-gravity fermentation. Food Science, 2007, 28(10): 381–383 (in Chinese)

Rathore S S S, Paulsen M R, Sharma V, Singh V. Optimization of yeast and enzyme dose for dry-grind corn fermentation process for ethanol production. Transactions of the ASABE, 2009, 52: 867–875

Srichuwong S, Arakane M, Fujiwara M, Zhang Z L, Takahashi H, Tokuyasu K. Alkali-aided enzymatic viscosity reduction of sugar beet mash for novel bioethanol production process. Biomass and Bioenergy, 2010, 34(9): 1336–1341

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, Y., Tian, H., Yao, K. et al. Simultaneous saccharification and fermentation of sweet potato powder for the production of ethanol under conditions of very high gravity. Front. Chem. Sci. Eng. 5, 318–324 (2011). https://doi.org/10.1007/s11705-010-1026-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-010-1026-3