A commercial phenol formaldehyde based resole thermosetting resin (Hexion “J2027L”) was filled with ceramic-based fillers (Envirospheres “slg”) to increase its strength and fracture toughness. By testing viscosity, strength, and fracture toughness at a range of filler addition levels, the optimal addition level of SLG was able to be determined in terms of workability, cost, and performance. It was found that the fracture toughness of this resin could be significantly increased through the addition of the slg filler. The results show that composite with 20% by weight of the slg produces the best balance between ease of casting and impact performance.

Similar content being viewed by others

References

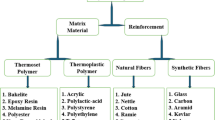

J.F. Shackelford, Introduction to Materials Science for Engineers, 3rd ed., Macmillan, 1992, p 435–437

W.F. Smith and J. Hashemir, Foundations of Material Science and Engineering, 4th ed., McGraw-Hill, 2006, p 523–525

A.B. Strong, Plastics: Materials and Processing, 3rd ed., Pearson/Prentice-Hall, 2006, p 182–183, 304–309, 323–333, 620–621

J.L. Clarke, Ed., Structural Design of Polymer Composites, E & FN Spon, U.K., 1996, p 59–62, 343–345, 357

L.M. Barker, Fracture Mechanics Applied to Brittle Materials, ASTM, STP 678, American Society for Testing and Materials, 1979, p 73–82

L.M. Baker, Development of the Short Rod Method of Fracture Toughness Measurement, Proceedings, Conference on Wear and Fracture Prevention, 21-22 May 1980, ASM, Metals Park, Ohio, p 163–180

L.M. Baker, Short Rod and Short Bar Fracture Toughness Specimen Geometries and Test Methods for Metallic Materials, Proceedings, Fracture Mechanics: Thirteenth Conference, ASMT STP 743, 1981, p 456–475

Chemwatch, Material Safety Data Sheet for Hexion Cellobond J2027L, 2005, p 1–14

Chemwatch, Material Safety Data Sheet for Hexion Phencat 15, 2005, p 1–14

M.J. Morgan, Engineering Materials—Study Book 1, University of Southern Queensland, 2006, p 9.13

D.R. Askeland, The Science and Engineering of Materials, 3rd ed., Stanley Thornes, 1998, p 163–164

W.D. Callister, Materials Science and Engineering: An Introduction, 7th ed., John Wiley and Sons, Inc., 2006, p 217–219

Munz D., Determination of Fracture Toughness of High Strength Aluminum Alloys with Cheron Notched Short Rod and Short Bar Specimens, Eng. Fract. Mech., Vol. 15, No. 1–2, 1981, p 231–236

B. Redjel, Mechanical Properties and Fracture Toughness of Phenolic Resin, Plast. Rubber Compos. Process. Appl., 1995, 24, p 221–228

Davey S.W., Heldt T., Van Erp G., Ayers Stephen, Vinyl Ester/Cenosphere Composite Materials for Civil and structural Engineering, FRP Intl., Vol. 2, No. 3, 2005, p 2–5

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ku, H., Rogers, D., Davey, R. et al. Fracture Toughness of Phenol Formaldehyde Composites: Pilot Study. J. of Materi Eng and Perform 17, 85–90 (2008). https://doi.org/10.1007/s11665-007-9115-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-007-9115-2