Abstract

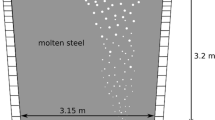

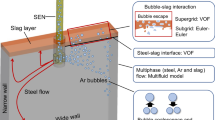

The bubble formation during gas injection into liquids was studied using a water model and a three-dimensional numerical model. In the experiment, a high-speed camera was used to record the bubble formation processes. Nozzle diameters of 0.5, 1, and 2 mm were investigated under both wetting and non-wetting conditions. The bubble sizes and formation frequencies as well as the bubbling regimes were identified for each nozzle size and for different wettabilities. The results show that the upper limits of the bubbling regime are 7.35, 12.05, and 15.22 L/h under wetting conditions for the 0.5, 1, and 2 mm nozzle diameters, respectively. Meanwhile, the limits are 12.66, 13.64, and 15.33 L/h for the non-wetting conditions. In the numerical model, the volume-of-fluid method was used to track the interface between the gas and liquid. The simulation results were compared with the experimental observations in the air–water system. The comparisons show a satisfactory good agreement between the two methods. The mathematical model was then applied to simulate the argon-steel system. Simulation results show that the effect of nozzle size is insignificant for the current studied metallurgical conditions. The upper limits of the bubbling regime are approximately 60 and 80 L/h for a 2-mm nozzle for the wetting and non-wetting conditions, respectively. In addition, a poor wettability leads to a bigger bubble and a lower frequency compared with a good wettability, for the same gas flow rate.

Similar content being viewed by others

Abbreviations

- \( \alpha_{\text{l}} \) :

-

Value of liquid volume fraction (−)

- \( \rho \) :

-

Density (kg m−3)

- \( \mu \) :

-

Viscosity (kg m−1 s−1)

- \( \sigma \) :

-

Surface tension coefficient (N m−1)

- \( \kappa \) :

-

Curvature (m−2)

- t:

-

Time (s)

- F s :

-

Surface tension force (N m−3)

- θ :

-

Contact angle (°)

- d B :

-

Bubble diameter (m)

- d N :

-

Nozzle diameter (m)

- f :

-

Bubble formation frequency (s−1)

- T :

-

Bubble formation period (s)

- V B :

-

Bubble volume (m3)

References

L. Davidson and E.H. Amick: AIChE J., 1956, vol. 2, pp. 337-42.

S. Ramakrishnan, R. Kumar and N.R. Kuloor: Chem. Eng. Sci., 1969, vol. 24, pp. 731-47.

A.A. Kulkarni and J.B. Joshi: Ind. Eng. Chem. Res., 2005, vol. 44, pp. 5873-931.

G.Q. Yang, B. Du and L.S. Fan: Chem. Eng. Sci., 2007, vol. 62, pp. 2-27.

R.J. Andreini, J.S. Foster and R.W. Callen: Metall. Trans. B, 1977, vol. 8B, pp. 625-31.

K.G. Davis, G.A. Irons and R.I.L. Guthrie: Metall. Trans. B, 1978, vol. 9B, pp. 721-22.

G.A. Irons and R.I.L. Guthrie: Metall. Trans. B, 1978, vol. 9B, pp. 101-10.

G.A. Irons and R.I.L. Guthrie: Can. Metall. Q., 1980, vol. 19, pp. 381-87.

K. Mori, Y. Ozawa and M. Sano: Trans. Iron Steel Inst. Jpn., 1982, vol. 22, pp. 377-84.

M. Iguchi, T. Chihara, N. Takanashi, Y. Ogawa, N. Tokumitsu and Z.i. Morita: ISIJ Int., 1995, vol. 35, pp. 1354-61.

M. Iguchi, H. Kawabata, K. Nakajima and Z.I. Morita: Metall. Mater. Trans. B, 1995, vol. 26B, pp. 67-74.

M. Iguchi and T. Chihara: Metall. Mater. Trans. B, 1998, vol. 29B, pp. 755-61.

W. Lou and M. Zhu: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 762-82.

S.T. Johansen and F. Boysan: Metall. Trans. B, 1988, vol. 19B, pp. 755-64.

Y. Xu, M. Ersson, and P. Jönsson: Steel Res. Int., 2015. DOI: 10.1002/srin.201400355.

R.I.L. Guthrie: International Conference on Injection Metallurgy, Jernkontoret, Sweden, 1980, pp. 6:1–31.

Y. Sahai and R.I.L Guthrie: Metall. Mater. Trans. B, 1982, vol. 13B, pp. 125-27.

M. van Sint Annaland, N.G. Deen, and J.A.M. Kuipers: Chem. Eng. Sci., 2005, vol. 60, pp. 2999- 3011.

C.W. Hirt and B.D. Nichols: J. Comput. Phys., 1981, vol. 39, pp. 201-25.

J. Brackbill, D.B. Kothe and C. Zemach: J. Comput. Phys., 1992, vol. 100, pp. 335-54.

Y. Zhang, M. Liu, Y. Xu and C. Tang: Chem. Eng. Sci., 2012, vol. 73, pp. 55-78.

R.I. Issa: J. Comput. Phys., 1986, vol. 62, pp. 40-65.

V.V. Buwa, D. Gerlach, F. Durst and E. Schlücker: Chem. Eng. Sci., 2007, vol. 62, pp. 7119-32.

Z. Wang, K. Mukai and D. Izu: ISIJ Int., 1999, vol. 39, pp. 154-63.

A. Alexiadis: Appl. Math. Model., 2007, vol. 31, pp. 1534-47.

H.P. Liu, Z.Y. Qi and M.G. Xu: Steel Res. Int., 2011, vol. 82, pp. 440-58.

Acknowledgments

Yonggui Xu would like to extend his sincere appreciation to the CSC (China Scholarship Council) for financial support of his PhD studies at KTH-Royal Institute of Technology, Sweden.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 24, 2015.

Rights and permissions

About this article

Cite this article

Xu, Y., Ersson, M. & Jönsson, P.G. A Mathematical Modeling Study of Bubble Formations in a Molten Steel Bath. Metall Mater Trans B 46, 2628–2638 (2015). https://doi.org/10.1007/s11663-015-0423-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0423-x