Abstract

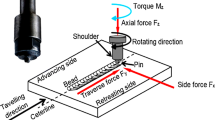

Notwithstanding the extensive interest in using friction stir processing (FSP) for producing metal matrix composite (MMC), more uniform powder distribution along the composite zone is still needed. In most studies, one groove is machined out of the specimen, filled with powder, and then processed by identical passes. In this investigation, an innovative technique was used that involved machining out of three gradient grooves with increasing depth from the advancing side to the retreating side instead of using a conventional sample with just a groove. Macro, optical, and scanning electron microscopy (SEM) images and microhardness test were used to evaluate the powder distribution. The images indicated that the most uniform distribution of SiC particles in the whole composite zone was related to a three-gradient grooves sample. Microohardness measurement of a three-gradient grooves sample, carried out along the cross section and perpendicular to the traverse direction of FSP, experiences less fluctuation in hardness compared with other techniques.

Similar content being viewed by others

References

K. Oh-ishi and T.R. McNelley: Metall. Mater. Trans. A., 2004, vol. 35A, pp. 2951-61.

Q.J. Su, T.W Nelson, and C.J. Sterling: Scripta Mater., 2005, vol. 52, pp. 135–40, 192–97.

T.U. Seidel and A.P. Reynolds: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 2879-87.

R.S. Mishra and Z.Y. Ma: Mater. Sci. Eng., 2005, vol. 50, pp. 1-78.

R.S. Mishra, Z.Y. Ma, and I. Charit: Mater. Sci. Eng. A, 2003, vol. 341, pp. 307-10.

A. Shafiei-Zarghani, S.F. Kashani-Bozorg, and A.F. Zarei-Hanzaki: Mater. Sci. Eng. A, 2009, vol. 500, pp. 84-91.

W. Wang, Q.Y shi, P. Liu, H. Ke, and T. Li: J. Mater. Process. Technol., 2009, vol. 209, pp. 2099-2103.

Y. Morisada, H. Fuji, T.K. Nagaoka, and K. Nogi: Mater. Sci. Eng. A, 2006, vol. 419, pp. 344-48.

B. Zahmatkesh and M.H. Enayati: Mater. Sci. Eng. A, 2010, vol. 527, pp. 6734-40.

M. Dixit, J.W. Newkirk, and R.S. Mishra: Scripta Mater., 2007, vol. 56, pp. 541-44.

A. Heydarian and K. Dehghani: 3rd International Conference on Ultrafine Grained and Nanostructured Materials, 2011.

K. Colligan: Weld. J., 1999, vol. 78, no. 7, pp. 229s-37s.

O. Lorrain, V. Favier, H. Zahrouni, and D. Lawrjaniec: J. Mater. Process. Technol., 2010, vol. 210, pp. 603-09.

M. Guerra, C. Schmidt, J.C. McClure, L.E. Murr, and A.C. Nunes: Mater. Charact., 2003, vol. 49, pp. 95-101.

J.A. Schneider and A.C. Nunes: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 777-83.

B.C. Liechty and B.W. Webb: J. Mater. Process. Technol., 2008, vol. 208, pp. 431-43.

W.L. Zhang, J.X. Wang, F. Yang, Z.Q. Sun, and M.Y. Gu: J. Compos. Mater., 2006, vol. 40, pp. 1117-31.

A. Yazdipour, A.M. Shafiei, and K. Dehghani: Mater. Sci. Eng. A, 2009, vol. 527, pp. 192-97.

Y.F. Sun and H. Fujii: Mater. Sci. Eng. A, 2011, vol. 528, pp. 5740-45.

V.C. Nardone and K.M. Prewo: Scripta Metall., 1986, vol. 20, pp. 43-48.

A. Zhang and D.L. Chen: Scripta Mater., 2006, vol. 54, pp. 1321-26.

K.V. Jata and S.L. Semiatin: Scripta Mater., 2000, vol. 43, pp. 743-49.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 19, 2013.

Rights and permissions

About this article

Cite this article

Heydarian, A., Dehghani, K. & Slamkish, T. Optimizing Powder Distribution in Production of Surface Nano-Composite via Friction Stir Processing. Metall Mater Trans B 45, 821–826 (2014). https://doi.org/10.1007/s11663-014-0025-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-014-0025-z