Abstract

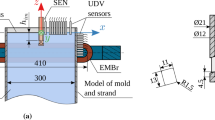

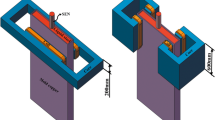

A computational fluid flow model is applied to investigate the effects of varying submerged entry nozzle (SEN) submergence depth and electromagnetic brake (EMBr) field strength on flow in the mold cavity. The three-dimensional, steady K-ε model of the nozzle and liquid cavity in the mold used the magnetic induction method in FLUENT to incorporate the localized-type static EMBr field measured at a steel plant. The model was validated by comparing results with an analytical solution and with nail board and oscillation mark measurements collected at the plant. Increasing EMBr strength at a constant SEN depth is found to cause a deeper jet impingement, weaker upper recirculation zone and meniscus velocity, and a smaller meniscus wave. Increasing SEN depth without EMBr caused the same trends. Increasing SEN depth at a constant EMBr strength brought about the opposite: higher meniscus velocity, larger meniscus wave, and deeper penetration depth. Using the knowledge gained from this model, electromagnetic forces can be controlled to stabilize the fluid flow in the mold cavity and thereby minimize casting defects.

Similar content being viewed by others

References

World Steel in Figures, International Iron and Steel Institute, Brussels, Belgium, 2006, www.worldsteel.org

M.M. Wolf: Steelmaking Conf. Proc., Toronto, 1992, ISS, Warrendale, PA, 1992, pp. 83–137

J. Herbertson: 74th Steelmaking Proc. of Iron & Steel Society, Washington, DC, 1991

K. Okazawa, T. Takehito, J. Fukuda, T. Kawase, M. Toki: ISIJ Int., 2001, vol. 41 (8), pp. 851–58

H.R. Hackl, A.F. Lehman, J.E.A. Eriksson, and S.G. Kollberg: AISTech Preliminary Program, AIST, Warrendale, PA, 2006

J. Nakashima, J.A. Kiyose, Y. Ohtani, J. Fukuda, T. Kawase, and M. Doki: Nippon Steel Technical Report No. 86, Nippon Steel, 2002, No. 86, pp. 61–67

T. Ishii, S.S. Sazhin, M. Makhlouf: Iron Steelmaking, 1996, vol. 23 (3), pp. 267–72

J. Kubota, K. Okimoto, A. Shirayama, and H. Murakami: 74th Steelmaking Conf. Proc., ISS-AIME, Warrendale, PA, 1991, pp. 233–38

P.H. Dauby, S. Kunstreich: Ironmaking and Steelmaking, 2005, vol. 32 (1), pp. 80–86

P.M. Lofgren, P. Hanley: AISTech Conf. Proc., 2004, vol. 2, pp. 977–84

M.Y. Ha, H.G. Lee, and S.H. Seong: J. Mater. Process. Technol., 2003, vol. 133 (3), pp. 322–39

K. Takatani, K. Nakai, N. Kasai, T. Watanabe, H. Nakajima: ISIJ Int., 1989, vol. 29 (12), pp. 1063–68

D.S. Kim, W.S. Kim, K.H. Cho: ISIJ Int., 2000, vol. 40 (7), pp. 670–76

H. Harada, T. Toh, T. Ishii, K. Kaneko, E. Takeuchi: ISIJ Int., 2001, vol. 41 (10), pp. 1236–44

M. Zeze, H. Harada, E. Takeuchi, and T. Ishii: 76th Steelmaking Conf., Dallas, TX, Mar. 1993, pp. 267–72

A. Idogawa, M. Sugizawa, S. Takeuchi, K. Sorimachi, T. Fujii: Mater. Sci. Eng. A, 1993, vol. A173 (1–2), pp. 293–97

B. Li, T. Okane, T. Umeda: Metall. Trans. B, 2000, vol. 31B, pp. 1491–1503

B.G. Thomas, Q. Yuan, S. Sivaramakrishnan, T. Shi, S.P. Vanka, M.B. Assar: ISIJ Int., 2001, vol. 41 (10), pp. 1266–76

Q. Yuan, B. Zhao, S.P. Vanka, B.G. Thomas: Steel Res. Int., 2005, vol. 76 (1,Special Issue: Simulation of Fluid Flow in Metallurgy), pp. 33–43

Q. Yuan, S. Sivaramakrishnan, S.P. Vanka, B.G. Thomas: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 967–82

B.E. Launder, D.B. Spalding: Mathematical Models of Turbulence, Academic Press, London, 1972, pp. 90–111

FLUENT6 .2-Manual, Fluent, Inc., Lebanon, NH, 2005

D.E. Hershey, B.G. Thomas, F.M. Najjar: Int. J. Numer. Methods Fluids, 1993, vol. 17 (1), pp. 23–47

Y. Meng, B.G. Thomas: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 685–705

B.T. Rietow: Master’s Thesis, University of Illinois at Urbana–Champaign, Urbana, IL, 2007

H. Bai, B.G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 253–67

Integrity Design and Research Corporation, http://www.gaussmeter.info/dc-gauss.html

R. McDavid, B.G. Thomas: Metall. Trans. B, 1996, vol. 27B, pp. 672–85

E. Takeuchi, J.K. Brimacombe: Metall. Trans. B, 1984, vol. 15B, pp. 493–509

R. Moreau: Magnetohydrodynamics, Kluwer Academic Pub. Co, Norwell, MA, 1990, pp. 110–64

M.J. Cho, I.C. Kim, S.J. Kim, J.K. Kim: Trans. KSME, 1999, vol. 23B (13), pp. 1491–1502

K. Rackers and B.G. Thomas: 78th Steelmaking Conf. Proc., Nashville, TN, Apr. 2, 1995, ISS, Warrendale, PA, vol. 78, pp. 723–34

D.T. Creech: Master’s Thesis, University of Illinois at Urbana–Champaign, Urbana, IL, 1999

Acknowledgments

The authors thank Ron O’Malley and Nucor Steel (Decatur, AL) for their assistance and use of their facilities for the experimental portion of this work. They also thank the Continuous Casting Consortium, University of Illinois at Urbana–Champaign, and the National Science Foundation (Grant No. DMI 05-00453) for support of this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 13, 2007.

Rights and permissions

About this article

Cite this article

Cukierski, K., Thomas, B.G. Flow Control with Local Electromagnetic Braking in Continuous Casting of Steel Slabs. Metall Mater Trans B 39, 94–107 (2008). https://doi.org/10.1007/s11663-007-9109-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-007-9109-3