Abstract

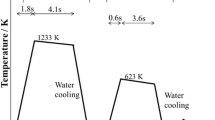

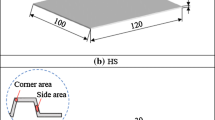

A deformation of a tempered martensitic structure (i.e., tempforming) at 773 K (500 °C) was applied to a 0.6 pct C-2 pct Si-1 pct Cr steel. The hydrogen embrittlement (HE) property of the tempformed (TF) steel was investigated by a slow strain rate test (SSRT) and an accelerated atmospheric corrosion test (AACT). Hydrogen content within the samples after SSRT and AACT was measured by thermal desorption spectrometry (TDS). The tempforming at 773 K (500 °C) using multipass caliber rolling with an accumulative are reduction of 76 pct resulted in the evolution of an ultrafine elongated grain (UFEG) structure with a strong 〈110〉//rolling direction (RD) fiber deformation texture and a dispersion of spheroidized cementite particles. The SSRT of the pre-hydrogen-charged notched specimens and the AACT demonstrated that the TF sample had superior potential for HE resistance to the conventional quenched and tempered (QT) sample at a tensile strength of 1500 MPa. The TDS analysis also indicated that the hydrogen might be mainly trapped by reversible trapping sites such as grain boundaries and dislocations in the TF sample, and the hydrogen trapping states of the TF sample were similar to those of the QT sample. The QT sample exhibited hydrogen-induced intergranular fracture along the boundaries of coarse prior-austenite grains. In contrast, the hydrogen-induced cracking occurred in association with the UFEG structure in the TF sample, leading to the higher HE resistance of the TF sample.

Similar content being viewed by others

References

J.P. Hirth: Metall. Trans. A, 1980, vol. 11A, pp. 861–90.

H.H. Johnson: Metall. Trans. B, 1988, vol. 19B, pp. 691–707.

W.Y. Choo and J.Y. Lee: Metall. Trans. A, 1982, vol. 13A, pp. 135–40.

S.M. Lee and J.Y. Lee: Acta Metall., 1987, vol. 35, pp. 2695–700.

H. Asahi, D. Hirakami, and S. Yamasaki: ISIJ Int., 2003, vol. 43, pp. 527–33.

R.P.M. Procter and H.W. Paxton: Trans. ASM, 1969, vol. 62, pp. 989–99.

S. Matsuyama: Tetsu-to-Hagané, 1972, vol. 58, pp. 395–410.

J.F. Lessar and W.W. Gerberich: Metall. Trans. A, 1976, vol. 7A, pp. 953–60.

S.K. Banerji, C.J. McMahon, Jr., and H.C. Feng: Metall. Trans. A, 1978, vol. 9A, pp. 237–47.

R. Padmanabhan and W.E. Wood: Metall. Trans. A, 1983, vol. 14A, pp. 2347–56.

W. Hui, H. Dong, Y. Weng, J. Shi, Y. Nie, Z. Zhu, and Y. Chen: Acta Metall. Sin., 2004, vol. 40, pp. 561–68.

S. Yamasaki, M. Kubota, and T. Tarui: Nippon Steel Technical Report, 1999, no. 80, pp. 50–55.

S. Terasaki, S. Sakashita, S. Takagi, Y. Kimura, and K. Tsuzaki: Proc. Workshop on New Generation Steel, The Chinese Society for Metals, Beijing, China, 2001, pp. 239–44.

Y. Kimura, Y. Sakai, T. Hara, A. Belyakov, and K. Tsuzaki: Scripta Mater., 2003, vol. 49, pp. 1111–16.

D.C. Langstaff, G. Meyrick, and J.P. Hirth: Corrosion, 1981, vol. 37, pp. 429–37.

D.G. Enos and J.R. Scully: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 1151–66.

J.S. Kim, Y.H. Lee, D.L. Lee, K.T. Park, and C.S. Lee: Mater. Sci. Eng. A, 2009, vol. 505, pp. 105–10.

Y. Kimura, T. Inoue, F. Yin, O. Sitdikov, and K. Tsuzaki: Scripta Mater., 2007, vol. 57, pp. 465–68.

Y. Kimura, T. Inoue, F. Yin, and K. Tsuzaki: Science, 2008, vol. 320, pp. 1057–60.

Y. Kimura, T. Inoue, F. Yin, and K. Tsuzaki: ISIJ Int., 2010, vol. 50, pp. 152–61.

T. Inoue, F. Yin, Y. Kimura, K. Tsuzaki, and S. Ochiai: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 341–55.

M. Jafari, Y. Kimura, Y. Nie, and K. Tsuzaki: ISIJ Int., 2010, vol. 50, pp. 1660–65.

M. Cojic and L. Kosec: ISIJ Int., 1997, vol. 37, pp. 412–18.

M. Wang, E. Akiyama, and K. Tsuzaki: Scripta Mater., 2005, vol. 52, pp. 403–08.

M. Wang, E. Akiyama, and K. Tsuzaki: Mater. Sci. Eng. A, 2005, vol. 398, pp. 37–46.

M. Wang, E. Akiyama, and K. Tsuzaki: Corros. Sci., 2007, vol. 49, pp. 4081–97.

E. Akiyama, K. Matsukado, M. Wang, and K. Tsuzaki: Corros. Sci., 2010, vol. 52, pp. 2758–65.

S. Li, Z. Zhang, E. Akiyama, K. Tsuzaki, and B. Zhang: Corros. Sci., 2010, vol. 52, pp. 1660–67.

S. Li, E. Akiyama, Y. Kimura, K. Tsuzaki, N. Uno, and B. Zhang: Sci. Technol. Adv. Mater., 2010, vol. 11, p. 025005.

W.J. Nam, C.S. Lee, and D.Y. Ban: Mater. Sci. Eng. A, 2000, vol. A289, pp. 8–17.

G. Miyamoto, J.C. Oh, K. Hono, T. Furuhara, and T. Maki: Acta Mater., 2007, vol. 55, pp. 5027–38.

M. Čerňanský, J. Čermák, N. Zárubová, and P. Wolf: J. Mater. Sci., 1996, vol. 31, pp. 995–1004.

T. Inoue, F. Yin, Y. Kimura, and K. Nagai: J. Japan Inst. Metals, 2005, vol. 69, pp. 943–52.

ASTM E23-05, 2005 Annual Book of ASTM Standards, 2005, pp. 158–84.

M. Ojima, Y. Adachi, Y. Tomota, K. Ikeda, T. Kamiyama, and Y. Katada: Mater. Sci. Eng. A, 2009, vol. A 527, pp. 16–24.

M. Calcagnotto, D. Ponge, E. Demir, and D. Raabe: Mater. Sci. Eng. A, 2010, vol. A527, pp. 2738–46.

T. Ungár, M. Victoria, P. Marmy, P. Hanak, and G. Szenes: J. Nucl. Mater., 2000, vol. 276, pp. 278–82.

M. Zamanzadeh, A. Allam, C. Kato, B. Ateya, and H.W. Pickering: J. Electrochem. Sci. Tech., 1982, vol. 129, pp. 284–89.

S. Sakashita, E. Akiyama, K. Tsuzaki, and T. Takahashi: CAMP-ISIJ, 2002, vol. 15, p. 576.

ASTM E112-96: 2005 Annual Book of ASTM Standards, ASTM International, West Conshohocken, PA, 2005, pp. 267–92.

G. Kurdjumov and G. Sachs: Z. Phys., 1930, vol. 64, pp. 325–43.

S. Morito, H. Tanaka, R. Konishi, T. Furuhara, and T. Maki: Acta Mater., 2003, vol. 51, pp. 1789–99.

A. Belyakov, Y. Kimura, Y. Adachi, and K. Tsuzaki: Mater. Trans., 2004, vol. 45, pp. 2812–21.

Y. Tomota, T. Suzuki, A. Kanie, Y. Shiota, M. Uno, A. Moriai, N. Minakawa, and Y. Morii: Acta Mater., 2005, vol. 53, pp. 463–67.

M.F. Ashby: Philos. Mag., 1970, vol. 21, pp. 399–424.

K. Takai, G. Yamauchi, M. Nakamura, and M. Nagumo: J. Japan Inst. Metals, 1998, vol. 62, pp. 267–75.

S. Yamasaki and T. Takahashi: Tetsu-to-Hagané, 1997, vol. 83, pp. 454–59.

Y. Kimura: Eng. Mater., 2009, vol. 57, pp. 34–35.

B.G. Pound: Acta Mater., 1998, vol. 46, pp. 5733–43.

H.G. Lee and J.Y. Lee: Acta Metall., 1984, vol. 32, pp. 131–36.

G.M. Pressouyre and I.M. Bernstein: Metall. Trans. A, 1981, vol. 12A, pp. 835–44.

K. Ebihara, H. Kaburaki, T. Suzudo, and K. Takai: ISIJ Int., 2009, vol. 49, pp. 1907–13.

K. Takai and R. Watanuki: ISIJ Int., 2003, vol. 43, pp. 520–26.

F.G. Wei, T. Hara, and K. Tsuzaki: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 587–97.

F.G. Wei and K. Tsuzaki: Scripta Mater., 2005, vol. 52, pp. 467–72.

F.G. Wei, T. Hara, T. Tsuchida, and K. Tsuzaki: ISIJ Int., 2003, vol. 43, pp. 539–47.

P. Novak, R. Yuan, B.P. Somerday, P. Sofronis, and R.O. Ritchie: J. Mech. Phys. Solid, 2010, vol. 58, pp. 206–26.

D. Li, R.P. Gangloff, and J.R. Scully: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 849–64.

H. Ohtani and C.J. McMahon, Jr.: Acta Metall., 1975, vol. 23, pp. 377–86.

Y. Kimura, S. Takagi, T. Hara, S. Terasaki, and K. Tsuzaki: J. Phys. IV, 2003, vol. 112, pp. 403–06.

G. Krauss: Steel: Heat Treatment and Processing Principles, 2nd ed., ASM International, Materials Park, OH, 1990, pp. 231–36.

K. Ameyama, T. Maki, and I. Tamura: J. Jpn. Inst. Metals, 1986, vol. 50, pp. 602–11.

T. Furuhara, S. Takagi, H. Watanabe, and T. Maki: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 1635–46.

Y. Yusa, T. Hara, K. Tsuzaki, and T. Takahashi: Mater. Sci. Eng. A, 1999, vols. 273–275, pp. 462–65.

S. Yusa, T. Hara, and K. Tsuzaki: J. Jpn. Inst. Metals, 2000, vol. 64, pp. 1230–38.

J.-Y. Lee and U.-I. Chung: Mater. Sci. Eng., 1987, vol. 95, pp. 273–80.

J.D. Embury, N.J. Petch, A.E. Wraith, and E.S. Wright: Trans. Metall. Soc. AIME, 1967, vol. 239, pp. 114–18.

D.W. Kum, T. Oyama, J. Wadsworth, and O.D. Sherby: J. Mech. Phys., 1983, vol. 31, pp. 173–86.

J.W. Morris, Jr., Z. Guo, C.R. Krenn, and Y.-H. Kim: ISIJ Int., 2001, vol. 41, pp. 599–611.

Acknowledgment

The authors thank Mr. Kuroda and Mr. Taniuchi for the materials processing with caliber-rolling, Ms. Hirota for her help with the TDS analysis, and Dr. Kameda for his suggestions for this study. The study for the QT samples was carried out as a part of research activities of Fundamental Studies on Technologies for Steel Materials with Enhanced Strength and Functions by the Consortium of The Japan Research and Development Center of Metals and the New Energy and Industrial Technology Development Organization. The study for the TF sample was partly supported by the Iketani Science and Technology Foundation and by the Japan Science and Technology Agency under collaborative research based on industrial demand Heterogeneous Structure Control: Towards Innovative Development of Metallic Structural Materials.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 29, 2010.

Rights and permissions

About this article

Cite this article

Nie, Y., Kimura, Y., Inoue, T. et al. Hydrogen Embrittlement of a 1500-MPa Tensile Strength Level Steel with an Ultrafine Elongated Grain Structure. Metall Mater Trans A 43, 1670–1687 (2012). https://doi.org/10.1007/s11661-011-0974-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0974-7