Abstract

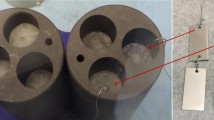

As part of the spent fuel treatment program at the Idaho National Laboratory, alternate crucible materials are being developed for the processing of uranium and salt. The separation of salt (LiCl/KCl based) from uranium is performed in an inductively heated furnace capable of distillation under vacuum conditions. Historically, salt and uranium have been processed in graphite crucibles coated with a zirconia mold wash. Although the coated crucibles have performed adequately considering the reactive nature of salt and uranium at high temperature, the operations required for multiple use of the crucibles are quite labor intensive. Thus, an alternate ceramic-lined crucible has been developed to simplify remote operations. Two ceramic-lined crucibles have been tested using irradiated materials to verify their compatibility and determine an ultimate life cycle. Although minor process losses and crucible deterioration have occurred with the ceramic-lined crucibles, the overall performance of the crucibles has been adequate for the separation of salt during uranium processing.

Similar content being viewed by others

Notes

ZYP is a trademark of ZYP Coatings, Inc., Oak Ridge, TN.

Zircoa is a trademark of Zircoa, Inc., Solon, OH.

Grefcon is a trademark of ANH Refractories Company, Moon Township, PA.

References

Y.I. Chang: Nucl. Technol., 1990, vol. 88, pp. 129–38.

R.W. Benedict and H.F. McFarlane: Radwaste, 1998, vol. 5, pp. 23–28.

B.R. Westphal and R.D. Mariani: JOM, 2000, vol. 52 (9), pp. 21–25.

D. Vaden, B.R. Westphal, S.X. Li, and T.A. Johnson: Nucl. Technol., 2008, vol. 162, pp. 124–28.

S.X. Li and M.F. Simpson: Min. Met. Proc., 2005, vol. 22 (4), pp. 192–98.

B.R. Westphal, J.C. Price, D. Vaden, and R.W. Benedict: J. Alloys Compd., 2007, vol. 444, pp. 561–64.

B.R. Westphal, D. Vaden, J.R. Liaw, and J.R. Krsul: Trans. Am. Nucl. Soc., 1997, vol. 76, pp. 74–76.

A.R. Brunsvold, P.D. Roach, and B.R. Westphal: Proc. ICONE 8, Baltimore, MD, Apr. 2–6, 2000.

B.R. Westphal, K.C. Marsden, J.C. Price, and D.V. Laug: Nucl. Eng. Technol., 2008, vol. 40 (3), pp. 163–74.

A. Roine: HSC Chemistry 5.0 Thermochemical Database, Outokumpu Research Oy, Pori, Finland, 2002.

Acknowledgments

The authors acknowledge the Fuel Conditioning Facility operations personnel for their contributions, the Analytical Laboratory organization for chemical services, and T.C. Totemeier for the metallographic data. This work was supported by the United States Department of Energy, Office of Nuclear Energy, Science, and Technology, under DOE-NE Idaho Operations Office Contract No. DE-AC07-05ID14517.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is based on a presentation given in the symposium “Materials for the Nuclear Renaissance,” which occurred during the TMS Annual Meeting, February 15–19, 2009, in San Francisco, CA, under the auspices of Corrosion and Environmental Effects and the Nuclear Materials Committees of ASM-TMS.

Rights and permissions

About this article

Cite this article

Westphal, B.R., Marsden, K. & Price, J. Development of a Ceramic-Lined Crucible for the Separation of Salt from Uranium. Metall Mater Trans A 40, 2861–2866 (2009). https://doi.org/10.1007/s11661-009-9957-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-9957-3