Abstract

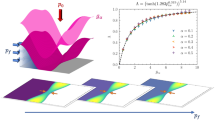

I study the influence of plastic deformations on the leakage of metallic seals. The solids are assumed to deform elastically as long as the stress is below the penetration hardness of the material, and yield plastically when the local stress reaches the penetration hardness. The metal surfaces are assumed to exhibit self-affine fractal surface roughness. We use the Persson contact mechanics theory and the Bruggeman effective medium theory to estimate the leak rate of the plastically deformed interface.

Similar content being viewed by others

Notes

It is assumed that the critical constriction can be approximated by a rectangular pore with a quadratic cross section (side w) in the xy plane, and the height \(u_{\mathrm{c}}\) (in the z-direction), which is much smaller than w. The condition \(u_{\mathrm{c}}\) ≪ w is predicted by contact mechanics theory and also found in exact numerical simulations. However, the assumption of a quadratic pore cross section in the xy plane is never exact and this introduces another correction factor \(\alpha \) in (1), determined by the exact shape of the critical constriction. Thus, very close to the percolation threshold, as observed with increasing pressure when all the surface roughness is included in the study, Dapp and Müser have shown in Ref. [17] that the width of the critical junction scales as \(\sim (1-p/p_{\mathrm{c}})^{0.60}\), while the length scales with \(\sim (1-p/p_{\mathrm{c}})^{0.45}\), where p is the nominal contact pressure and \(p_{\mathrm{c}}\) the pressure at percolation (see also [18]). However, in our theory one is usually not close to the percolation threshold where the fluid leakage would vanish. When the contact is studied (at any given nominal contact pressure p) at the magnification where the non-contact area percolate, i.e., for \(A(\zeta )/A_{0} \approx 0.42\), there is usually still roughness at shorter length scales, and when this is included the pore will “open up”, and we will in general no longer be close to percolation threshold. Thus the strong elongation of the critical constriction which is expected close to the true percolation threshold (which is observed with an increase in the nominal contact pressure when all the roughness is included in the study) will not exist in most practical cases. In the Bruggeman theory which I actually use in the calculations the problem of the shape of the critical constriction does not enter!

References

What determines seal leakage? Fluid Sealing Association (May 2008). http://www.fluidsealing.com/sealingsense/may08.pdf

Armand, G., Lapujoulade, J., Paigne, J.: A theoretical and experimental relationship between the leakage of gases through the interface of two metals in contact and their superficial micro-geometry. Vacuum 14, 53 (1964)

Nurhadiyanto, D.: Influence of Surface Roughness on Leakage of Corrugated Metal Gasket, Dissertation, Yamaguchi University, Japan, September 2014; See also: Haruyama, S., Nurhadiyanto, D., Choiron, M.A., Kaminishi, K. Influence of surface roughness on leakage of new metal gasket. Int. J. Press. Vessels Pip. 111–112, 146 (2013)

Perez-Rafols, F.: Modelling and Numerical Analysis of Leakage Through Metal-to-Metal Seals, Licentiate thesis, Lulea University of Technology Department of Engineering Science and Mathematics, Division of Machine Elements (2016). http://pure.ltu.se/portal/files/105667647/Francesci_P_rez_R_fols.pdf

Perez-Rafols, F., Larsson, R., Almqvist, A.: Modelling of leakage on metal-to-metal seals. Tribol. Int. 94, 421 (2016)

Persson, B.N.J., Yang, C.: Theory of the leak-rate of seals. J. Phys. Condens. Matter 20, 315011 (2008)

Persson, B.N.J., Albohr, O., Tartaglino, U., Volokitin, A.I., Tosatti, E.: On the nature of surface roughness with application to contact mechanics, sealing, rubber friction and adhesion. J. Phys. Condens. Matter 17, R1 (2004)

Lorenz, B., Persson, B.N.J.: Leak rate of seals: effective-medium theory and comparison with experiment. Eur. Phys. J. E 31, 159 (2010)

Lorenz, B., Persson, B.N.J.: Leak rate of seals: comparison of theory with experiment. EPL 86, 44006 (2009)

Lorenz, B., Persson, B.N.J.: Time-dependent fluid squeeze-out between solids with rough surfaces. Eur. Phys. J. E 32, 281 (2010)

Dapp, W.B., Lucke, A., Persson, B.N.J., Müser, M.H.: Self-affine elastic contacts: percolation and leakage. Phys. Rev. Lett. 108, 244301 (2012)

Bottiglione, F., Carbone, G., Mangialardi, L., Mantriota, G.: Leakage mechanism in flat seals. J. Appl. Phys. 106, 104902 (2009)

Perez-Rafols, F., Larsson, R., van Riet, E.J., Almqvist, A.: On the flow through plastically deformed surfaces under loading. A frequency based approach. In: Proceedings of the iMeche, Part C: Journal of Mechanical Engineering Science (under review)

Pei, L., Hyun, S., Molinari, J.F., Robbins, M.O.: Finite element modeling of elasto-plastic contact between rough surfaces. J. Mech. Phys. Solids 53, 2385 (2005)

Kadin, Y., Kligerman, Y., Etsion, I.: Unloading an elastic plastic contact of rough surfaces. J. Mech. Phys. Solids 54, 2652 (2006)

Zhao, B., Zhang, S., Wang, P., Hai, Y.: Loading unloading normal stiffness model for power-law hardening surfaces considering actual surface topography. Tribol. Int. 90, 332 (2015)

Dapp, W.B., Müser, M.H.: Contact mechanics of and Reynolds flow through saddle points. EPL 109, 44001 (2015)

Dapp, W.B., Müser, M.H.: Fluid leakage near the percolation threshold. Sci. Rep. 6, 19513 (2016)

Persson, B.N.J.: Theory of rubber friction and contact mechanics. J. Chem. Phys. 115, 3840 (2001)

Yang, C., Persson, B.N.J.: Contact mechanics: contact area and interfacial separation from small contact to full contact. J. Phys. Condens. Matter 20, 215214 (2008)

Almqvist, A., Campana, C., Prodanov, N., Persson, B.N.J.: Interfacial separation between elastic solids with randomly rough surfaces: comparison between theory and numerical techniques. J. Mech. Phys. Solids 59, 2355 (2012)

Persson, B.N.J., Scaraggi, M.: Lubricated sliding dynamics: flow factors and Stribeck curve. Eur. Phys. J. E 34, 1 (2011)

Persson, B.N.J., Lorenz, B., Volokitin, A.I.: Heat transfer between elastic solids with randomly rough surfaces. Eur. Phys. J. E 31, 3 (2010); see also: B.N.J. Persson. Surface Science Reports 61, 201 (2006)

Persson, B.N.J.: On the fractal dimension of rough surfaces. Tribol. Lett. 54, 99 (2014)

Persson, B.N.J.: Contact mechanics for layered materials with randomly rough surfaces. J. Phys. Condens. Matter 24, 095008 (2012)

Persson, B.N.J.: Sliding Friction: Physical Principles and Applications. Springer, Heidelberg (2000)

Gnecco, E., Meyer, E.: Elements of Friction Theory and Nanotribology. Cambridge University Press, Cambridge (2015)

Acknowledgments

This work was performed within a Reinhart–Koselleck project funded by the Deutsche Forschungsgemeinschaft (DFG). We would like to thank DFG for the project support under the reference German Research Foundation DFG-Grant: MU 1225/36-1. The research work was also supported by the DFG-Grant: PE 807/10-1. This work is supported in part by COST Action MP1303.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Persson, B.N.J. Leakage of Metallic Seals: Role of Plastic Deformations. Tribol Lett 63, 42 (2016). https://doi.org/10.1007/s11249-016-0728-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-016-0728-1