A generalized model is developed for calculating the fatigue limit of the material based on the data on its microstructure. The experimental results of fatigue and cyclic fracture toughness tests and the data on the analysis of the microstructure of two-phase (α + β) titanium VT3-1 alloy with a different microstructure (globular, bimodal and fine lamellar microstructure) have shown that the dependence of the fatigue limit on the structural parameter, which is responsible for the material fatigue strength, has a nonlinear S-like nature. The formula for calculating the fatigue limit is justified by the data on the microstructural parameters and by the results of static tensile tests of the material, with a fair agreement obtained between the calculated and experimental results. The model has been validated for materials with another type of the crystal lattice [steel containing 0.16% C with a body-centered cubic lattice (bcc) and brass 70/30 with a face-centered cubic lattice (fcc)] and has shown a satisfactory agreement between the experimental and calculation results.

Similar content being viewed by others

References

E. O. Hall, “The deformation and ageing of mild steel. III. Discussion of results,” Proc. Phys. Soc. London, B64, 747–753 (1951).

A. Cracknell and N. J. Patch, “Frictional forces on dislocation at lower yield point in iron,” Acta Met., 3, 186–189 (1955).

R. W. Armstrong, “The influence of polycrystal grain size on several mechanical properties of materials,” Metall. Trans., 1, 1169–1176 (1970).

V. V. Panasyuk (Ed.), Fracture Mechanics and Strength of Materials, Handbook in 4 volumes, Vol. 4: O. N. Romaniv, S. Ya. Yarema, and G. N. Nikiforchin (Eds.), Fatigue and Cyclic Fracture Toughness of Structural Materials [in Russian], Naukova Dumka, Kiev (1990).

V. T. Troshchenko (Ed.), Material Resistance to Deformation and Fracture [in Russian], Handbook in 2 volumes, Naukova Dumka, Kiev (1993).

M. M. El Haddad, K. N. Smith, and T. U. Topper, “Fatigue crack propagation of short cracks,” Trans. ASME, J. Eng. Mater. Technol., 101, No. 1, 42–46 (1979).

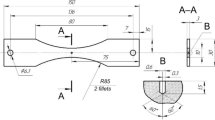

V. T. Troshchenko, B. A. Gryaznov, Yu. S. Nalimov, et al., “Fatigue strength and cyclic crack resistance of titanium alloy VT3-1 in different structural states. Communication 1. Study procedure and experimental results,” Strength Mater., 27, No. 5–6, 245–251 (1995).

O. N. Herasimchuk, Endurance and Cyclic Crack Growth Resistance of Titanium Alloy VT3-1 in Different Structural States [in Russian], Author’s Abstract of the Candidate Degree Thesis (Tech. Sci.), Kiev (1995).

V. N. Gridnev, O. M. Ivasishin, and S. P. Oshkaderov, Physical Foundations for High-Speed Thermal Hardening of Titanium Alloys [in Russian], Naukova Dumka, Kiev (1986).

Mechanical Properties of a Titanium Blading Alloy, CS-2933. Final Report EPRI Research Project (Oct. 1983).

P. K. Liaw, T. R. Leax, and W. A. Logston, “Near-threshold fatigue crack growth behaviour in metals,” Acta Met., 31, No. 10, 1581–1587 (1983).

RD 50-345-82. Strength Analysis and Tests. Methods for Mechanical Testing of Metals. Determination of Fracture Toughness Characteristics under Cyclic Loading (Methodological Recommendations) [in Russian], Izd. Standartov, Moscow (1983).

A. Ya. Krasovskii, Physical Foundations for Strength [in Russian], Naukova Dumka, Kiev (1977).

K. J. Miller, “The two thresholds of fatigue behaviour,” Fatigue Fract. Eng. Mater. Struct., 16, No. 9, 931–939 (1993).

H. Abdel-Raouf, D. L. DuQuesnay, T. H. Topper, and A. Plumtree, “Notch-size effects in fatigue based on surface strain redistribution and crack closure,” Int. J. Fatigue, 14, No. 1, 57–62 (1992).

G. Lutjering and J. C. Williams, Titanium, Springer Verlag, Berlin; Heidelberg (2003).

V. S. Ivanova and V. F. Terent’ev, Nature of the Fatigue of Metals [in Russian], Metalluguiya, Moscow (1975).

G. M. Sinclair and W. J. Craig, “Influence of grain size on work hardening and fatigue characteristics of alpha brass,” Trans. ASM, 44, 929–940 (1952).

P. G. Forest and A. E. L. Tate, “The influence of grain size on the fatigue behaviour of 70/30 brass,” J. Inst. Metals, 93, 438–444 (1965).

V. F. Terent’ev and V. G. Poida, Fatigue and Fracture Toughness of Metals [in Russian], Nauka, Moscow, (1974), pp. 109–140.

T. Ekobori, Physics and Mechanics of Fracture and Strength of Solids [Russian translation], Metallurgiya, Moscow (1971).

P. B. Mikhailov-Mikheev, Handbook on Metallic Materials in Turbine and Engine Construction [in Russian], Mashgiz, Moscow (1961).

Author information

Authors and Affiliations

Additional information

Translated from Problemy Prochnosti, No. 2, pp. 128 – 144, March – April, 2011.

Rights and permissions

About this article

Cite this article

Herasymchuk, O.M. A generalized grain-size dependence of the fatigue limit. Strength Mater 43, 205–216 (2011). https://doi.org/10.1007/s11223-011-9287-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-011-9287-8