ABSTRACT

Purpose

This study utilized a combination of computational fluid dynamics (CFD) and standardized entrainment tubes to investigate the influence of turbulence on the break-up and aerosol performance of a model inhalation formulation.

Methods

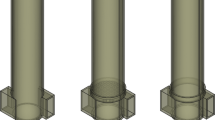

Agglomerates (642.8 μm mean diameter) containing 3.91 μm median diameter primary spherical mannitol particles were prepared by spheronisation. A series of entrainment tubes with different Venturi sections were constructed in silico, and the flow pattern and turbulence/impaction parameters were predicted using CFD. The entrainment models were constructed from the in silico model using three-dimensional printing. The aerosol performance of the mannitol was assessed by entraining the agglomerates into the experimental tubes at a series of flow rates and assessing the size distribution downstream of the venturi via in-line laser diffraction.

Results

A series of parameters (including Reynolds number (Re), turbulence kinetic energy, turbulence eddy frequency, turbulence length-scale, velocity and pressure drop) were calculated from the CFD simulation. The venturi diameter and volumetric flow rate were varied systematically. The particle size data of the agglomerated powders were then correlated with the CFD measurements. No correlation between turbulence and aerosol performance could be made (i.e. at a Reynolds number of 8,570, the d0.1 was 52.5 μm ± 19.7 μm, yet at a Reynolds number of 12,000, the d0.1 was 429.1 μm ± 14.8 μm). Lagrangian particle tracking indicated an increase in the number of impactions and the normal velocity component at the wall, with increased volumetric airflow and reduced venturi diameter. Chemical analysis of the mannitol deposited on the walls showed a linear relationship with respect to the theoretical number of impactions (R2 = 0.9620). Analysis of the relationship between the CFD results and the experimental size data indicated a critical impact velocity was required to initiate agglomerate break-up (∼0.4 m.s−1).

Conclusion

While this study focussed on the effect of turbulence on agglomerate break-up, the small amount of impaction, which inevitably occurs in the venturi assembly, appeared to dominate agglomerate break-up in this dry powder system.

Similar content being viewed by others

REFERENCES

Smith IJ, Parry-Billings M. The inhalers of the future? A review of dry powder devices on the market today. Pulm Pharmacol Ther. 2003;16(2):79–95.

Newman SP, Busse WW. Evolution of dry powder inhaler design, formulation, and performance. Resp Med. 2002;96(5):293–304.

Islam N, Gladki E. Dry powder inhalers (DPIs)—A review of device reliability and innovation. Int J Pharm. 2008;360(1–2):1–11.

Calvert G, Ghadiri M, Tweedie R. Aerodynamic dispersion of cohesive powders: A review of understanding and technology. Adv Powder Technol. 2009;20(1):4–16.

Voss A, Finlay WH. Deagglomeration of dry powder pharmaceutical aerosols. Int J Pharm. 2002;248(1–2):39–50.

Wang ZL, Lange CF, Finlay WH. Use of an impinging jet for dispersion of dry powder inhalation aerosols. Int J Pharm. 2004;275(1–2):123–31.

Louey MD, Van Oort M, Hickey AJ. Standardized entrainment tubes for the evaluation of pharmaceutical dry powder dispersion. J Aerosol Sci. 2006;37(11):1520–31.

Kurkela JA, Brown DP, Raula J, Kauppinen EI. New apparatus for studying powder deagglomeration. Powder Technol. 2008;180(1–2):164–71.

Gac J, Sosnowski TR, Gradon L. Turbulent flow energy for aerosolization of powder particles. J Aerosol Sci. 2008;39(2):113–26.

Thornton C, Liu LF. How do agglomerates break? Powder Technol. 2004;143–4:110–6.

Moreno R, Ghadiri M, Antony SJ. Effect of the impact angle on the breakage of agglomerates: a numerical study using DEM. Powder Technol. 2003;130(1–3):132–7.

Yang RY, Yu AB, Choi SK, Coates MS, Chan HK. Agglomeration of fine particles subjected to centripetal compaction. Powder Technol. 2008;184(1):122–9.

Iimura K, Watanabe S, Suzuki M, Hirota M, Higashitani K. Simulation of entrainment of agglomerates from plate surfaces by shear flows. Chem Eng Sci. 2009;64(7):1455–61.

Guo Y, Kafui KD, Wu CY, Thornton C, Seville JPK. A coupled DEM/CFD analysis of the effect of air on powder flow during die filling. AIChE J. 2009;55(1):49–62.

Kloss C, Kahrimanovic D, Pirker S, editors. Coupling of DEM and CFD—Simulation and experiment. DANSIS Meeting on Discrete Element Methods; 2009; Kopenhagen.

Coates MS, Chan HK, Fletcher DF, Raper JA. Influence of air flow on the performance of a dry powder inhaler using computational and experimental analyses. Pharm Res. 2005;22(9):1445–53.

Longest PW, Vinchurkar S. Validating CFD predictions of respiratory aerosol deposition: Effects of upstream transition and turbulence. J Biomech. 2007;40(2):305–16.

Ma B, Lutchen K. CFD simulation of aerosol deposition in an anatomically based human large-medium airway model. Ann Biomed Eng. 2009;37(2):271–85.

Coates MS, Chan HK, Fletcher DF, Raper JA. Effect of design on the performance of a dry powder inhaler using computational fluid dynamics. Part 2: Air inlet size. J Pharm Sci. 2006;95(6):1382–92.

Coates MS, Fletcher DF, Chan HK, Raper JA. The role of capsule on the performance of a dry powder inhaler using computational and experimental analyses. Pharm Res. 2005;22(6):923–32.

Coates MS, Fletcher DF, Chan HK, Raper JA. Effect of design on the performance of a dry powder inhaler using computational fluid dynamics. Part 1: Grid structure and mouthpiece length. J Pharm Sci. 2004;93(11):2863–76.

Longest PW, Hindle M. Evaluation of the respimat soft mist inhaler using a concurrent CFD and in vitro approach. J Aerosol Med Pulm D. 2009;22(2):99–112.

Coates MS, Chan HK, Fletcher DF, Chiou H. Influence of mouthpiece geometry on the aerosol delivery performance of a dry powder inhaler. Pharm Res. 2007;24(8):1450–6.

Adi H, Kwok P, Crapper J, Young PM, Traini D, Chan HK. Does electrostatic charge affect powder aerosolisation? J Pharm Sci. 2009;Accepted 18th Sept 2009.

Menter FR. 2-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994;32(8):1598–605.

Chew NY, Chan HK. Influence of particle size, air flow, and inhaler device on the dispersion of mannitol powders as aerosols. Pharm Res. 1999;16(7):1098–103.

Jaeger HM, Nagel SR. Physics of the granular state. Science. 1992;255(5051):1523–31.

Mendes PJ, Pinto JF, Sousa JMM. Non-dimensional functional relationship for the fine particle fraction produced by dry powder inhalers. J Aerosol Sci. 2007;38(6):612–24.

Thornton C, Yin KK, Adams MJ. Numerical simulation of the impact fracture and fragmentation of agglomerates. J Phys D Appl Phys. 1996;29(2):424–35.

Subero J, Ning Z, Ghadiri M, Thornton C. Effect of interface energy on the impact strength of agglomerates. Powder Technol. 1999;105(1–3):66–73.

ACKNOWLEDGEMENTS

This research was supported under the Australian Research Council’s Linkage Projects funding scheme (project LP0776892). The views expressed herein are those of the authors and are not necessarily those of the Australian Research Council.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wong, W., Fletcher, D.F., Traini, D. et al. Particle Aerosolisation and Break-up in Dry Powder Inhalers 1: Evaluation and Modelling of Venturi Effects for Agglomerated Systems. Pharm Res 27, 1367–1376 (2010). https://doi.org/10.1007/s11095-010-0128-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-010-0128-4