Abstract

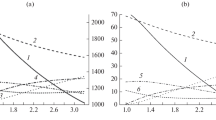

The research shows theoretical calculations on the thermodynamics of digestion/gasification processes where glucose is used as a surrogate for biomass. The change in Enthalpy (∆H) and Gibbs Free Energy (∆G) is used to obtain the Attainable Region (AR) that shows the overall thermodynamic limits for digestion/gasification from 1 mol of glucose. Gibbs Free Energy and Enthalpy (G–H) plots were calculated for the temperature range 25–1500 °C. The results show the effect of temperature on the AR for the processes when water is in both liquid and gas states using 25 °C, 1 bar as the reference state. The AR results show that the production of CO, H2, CH4 and CO2 are feasible at all temperatures studied. The minimum Gibbs Free Energy becomes more negative from −418.68 kJ mol−1 at 25 °C to −3024.34 kJ mol−1 at 1500 °C while the process shifts from exothermic (−141.90 kJ mol−1) to endothermic (1161.80 kJ mol−1) for the respective temperatures. Methane and carbon dioxide are favoured products (minimum Gibbs Free Energy) for temperatures up to about 600 °C, and this therefore includes Anaerobic Digestion. The process is exothermic below 500 °C, and thus Anaerobic Digestion requires heat removal. As the temperature continues to increase, hydrogen production becomes more favourable than methane production. The production of gas is endothermic above 500 °C, and it needs a supply of heat that could be done, either by combustion or by electricity (plasma gasification). The calculations show that glucose conversion at temperatures around 700 °C favours the production of carbon dioxide and hydrogen at minimum G. Generally, the results show that the gas from high-temperature gasification (>~800 °C) typically carries the energy mainly in syngas components CO and H2, whereas at low-temperature gasification (<500 °C) the energy is carried in CH4. The overall analysis for the temperature range (25–1500 °C) also suggests a close relationship between biogas production/digestion and gasification as biogas production can be referred to as a form of low-temperature gasification.

Similar content being viewed by others

Abbreviations

- AR:

-

Attainable Region

- WGS:

-

Water gas shift

- G–H :

-

Gibbs Free Energy–Enthalpy

- ε :

-

Extent of reaction

- T :

-

Temperature

- T o :

-

Reference temperature

- \(\Delta H^{^\circ }\) :

-

Heat of formation at T

- \(\Delta Ho^{^\circ }\) :

-

Heat of formation at T o

References

Heberlein J, Murphy A. Thermal plasma waste treatment. J Phys D Appl Phys. 2008;41:1–19.

Evangelisti S, Tagliaferri C, Clift R, Lettieri P, Taylor R, Chapman C. Integrated gasification and plasma cleaning for waste treatment: a life cycle perspective. Waste Manag. 2015;43:485–96.

Plis A, Kotyczka-Moran´ska M, Kopczyn´ski M, Łabojko G. Furniture wood waste as a potential renewable energy source, a thermogravimetric and kinetic analysis. J Therm Anal Calorim. 2016;125:1357–71.

Magdziarz A, Wilk M. Thermal characteristics of the combustion process of biomass and sewage sludge. J Therm Anal Calorim. 2013;114:519–29.

Raheem A, Sivasangar S, Azlina WAKGW, Yap YHT, Danquah MK, Harun R. Thermogravimetric study of Chlorella vulgaris for syngas production. Algal Res. 2015;12:52–9.

Portofino S, Donatelli A, Iovanne P, Innella C, Civita R, Martino M, Matera DA, Russo A, Cornacchia G, Galvano S. Steam gasification of waste tyre: influence of process temperature on yield and product composition. Waste Manag. 2013;33:672–8.

Pacioni TR, Soares D, Di Domenico M, Rosa MF, Moreira RF, José HJ. Bio-syngas production from agro-industrial biomass residues by steam gasification. Waste Manag. 2016;58:221–9.

Lombardi L, Carnevale E, Corti A. Analysis of energy recovery potential using innovative technologies of waste gasification. Waste Manag. 2012;32:640–52.

Hrabovsky M, Hlina M, Kavka T, Konrad M, Chumak O, Maslani A. Thermal plasma gasification of biomass for fuel gas production. High Temp Mater Process Int Q High Technol Plasma Process. 2009;13(3–4):299–313.

Leal-Quir´os E. Plasma processing of municipal solid waste. Braz J Phys. 2004;34:4B.

Glasser D, Hildebrandt D, Crowe CA. A geometric approach to steady flow reactors: the Attainable Region and optimization in concentration space. Ind Eng Chem Resour. 1987;26:1803–10.

Sempuga BC, Hausberger B, Patel B, Hildebrandt D, Glasser D. Classification of chemical processes: a graphical approach to process synthesis to improve reactive process work efficiency. Ind Eng Chem Res. 2010;49(17):8227–37.

Okonye LU, Hildebrandt D, Glasser D, Patel B. Attainable Regions for a reactor: application of G–H plot. Chem Eng Res Des. 2012;90:1590–609.

Ming D, Glasser D, Hildebrandt D. Application of attainable region theory to batch reactors. Chem Eng Sci. 2013;99:203–14.

Chimwani N, Mulenga F, Hildebrandt D, Glasser D, Bwalya M. Scale-up of batch grinding data for simulation of industrial milling of platinum group minerals ore. Miner Eng. 2014;63:100–9.

Danha G, Hildebrandt D, Glasser D, Bhondayi C. A laboratory scale application of the attainable region technique on a platinum ore. Powder Technol. 2014;274:14–9.

Nanda S, Dalai AK, Gökalp I, Kozinski JA. Valorization of horse manure through catalytic supercritical water gasification. Waste Manag. 2016;52:147–58.

Vassilev SV, Baxter D, Andersen LK, Vassileva CG. An overview of the chemical composition of biomass. Fuels. 2010;89:913–33.

Morrin S, Lettieri P, Chapman C, Taylor R. Fluid bed gasification—plasma converter process generating energy from solid waste: experimental assessment of sulphur species. Waste Manag. 2014;34:28–35.

Šulc J, Štojdl J, Richter M, Popelka J, Svoboda K, Smetana J, Vacek J, Skoblja S, Buryan P. Biomass waste gasification—can be the two stage process suitable for tar reduction and power generation? Waste Manag. 2012;32:692–700.

Smith JM, Abbott MM, Van Ness HC. Introduction to chemical engineering. Thermodynamics. 7th ed. 2001.

Wang L-Q, Dun Y-H, Tang H, Wang T-Z. A biomass gasification system for synthesis gas from the new method. Nat Sci. 2009;1(3):195–203.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Muvhiiwa, R.F., Lu, X., Hildebrandt, D. et al. Applying thermodynamics to digestion/gasification processes: the Attainable Region approach. J Therm Anal Calorim 131, 25–36 (2018). https://doi.org/10.1007/s10973-016-6063-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-6063-9