Abstract

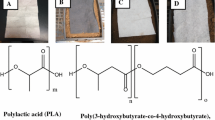

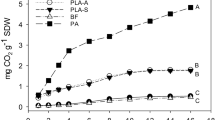

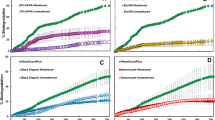

The soil degradation of fully biobased agricultural mulches prepared from polylactic acid (PLA) and blends of PLA and poly3-hydroxybutyrate-co-4-hydroxybutyrate (polyhydroxyalkanoate, or PHA) using nonwoven textile technology was compared to that of a commercial biodegradable mulch film, BioTelo (Dubois Agrinovation, Waterford, Canada). The addition of PHA to PLA to the feedstock blend produced nonwovens that possessed lower tensile strength and molecular weight and increased the average fiber diameter of mulches. A meltblown (MB) nonwoven mulch prepared from a PLA–PHA 72/28 w/w blend underwent the greatest degradation, achieving a 78 % loss of tensile strength and a 25.9 % decrease of weight-averaged molecular weight during 10 and 30 week of soil burial, respectively. The mass fraction of PHA decreased during soil burial, suggesting the preferential microbial assimilation of PHA over PLA. BioTelo underwent a 29 % loss of tensile strength but no appreciable change of molecular weight for its chloroform-soluble components. In contrast, spunbond (SB) PLA mulches did not undergo any appreciable degradation during the 30 week soil burial studies. The results suggest that the MB–PLA + PHA nonwoven may serve as a potentially valuable biodegradable agricultural mulch, and that SB–PLA may be useful as a compostable material for long-term agricultural applications, such as row covers and landscape fabrics. A soil degradation study of MB–PLA + PHA that directly compared untreated compost-enriched soil to sterilized soil-compost mixture demonstrated that the loss of tensile strength occurred only in the unsterilized soil, suggesting this event is directly associated with soil microorganisms.

Similar content being viewed by others

Abbreviations

- BDM:

-

“Biodegradable” mulch

- CB:

-

Carbon black (dyeing agent)

- CFU:

-

Colony forming units (quantification of microorganisms)

- DSC:

-

Differential scanning calorimetry

- GPC:

-

Gel permeation chromatography

- LSD:

-

Least significant difference (statistical analysis method)

- MB:

-

Meltblown nonwoven mulches

- Mw :

-

Weight-averaged molecular weight

- PDI:

-

Polydispersity index

- PHA:

-

Polyhydroxyalkanoate

- PLA:

-

Poloylactic acid

- SB:

-

Spunbond nonwoven mulches

- SEM:

-

Scanning electron microscopy

- Tc :

-

Crystallization temperature (°C)

- Tg :

-

Glass transition temperature (°C)

- Tm :

-

Melting temperature (°C)

- UT:

-

University of Tennessee

- Xc,PLA :

-

Fraction of PLA residing in crystalline morphology

- ΔHc :

-

Crystallization enthalpy (J g−1)

- ΔHm :

-

Melting enthalpy (J g−1)

References

Espi E, Salmeron A, Fontecha A, Garcia Y, Real AI (2006) Plastic films for agricultural applications. J Plast Film Sheeting 22:85–102

Lamont WJ Jr (2005) Plastics: modifying the microclimate for the production of vegetable crops. HortTechnology 15:477–481

Kasirajan S, Ngouajio M (2012) Polyethylene and biodegradable mulches for agricultural applications: a review. Agron Sustain Dev 32:501–529

McCraw D, Motes JE (1991) Use of plastic mulch and row covers in vegetable production (Oklahoma State University Extension Fact Sheet HLA-6034). Stillwater, OK

Briassoulis D, Dejean C (2010) Critical review of norms and standards for biodegradable agricultural plastics part I: biodegradation in soil. J Polym Environ 18:384–400

Lemieux PM (1997) Evaluation of emissions from the open burning of household waste in barrels (EPA Report 600/R-97-134a). Environmental Protection Agency, Washington

Levitan L (2005) Reducing dioxin emissions by recycling agricultural plastics: creating a viable alternative to open burning. Great Lakes Regional Pollution Prevention Roundtable, New York

Hayes DG, Dharmalingam S, Wadsworth LC, Leonas KK, Miles C, Inglis DA (2012) Biodegradable agricultural mulches derived from biopolymers. In: Khemani KC, Scholz C (eds) Degradable polymers and materials: principles and practice (2nd Edition; ACS Symposium Series, Volume 1114). American Chemical Society, Washington, pp 201–223

Martin-Closas L, Pelacho AM (2011) Agronomic potential of biopolymer films. In: Plackett D (ed) Biopolymers-new materials for sustainable films and coatings. Wiley, West Sussex

Bos U, Makishi C, Fischer M (2008) Life cycle assessment of common used agricultural plastic products in the EU. Acta Hort 801:341–350

Hussain I, Hamid H (2003) Plastics in agriculture. In: Andrady AL (ed) Plastics and the environment. Wiley, New York, pp 185–209

Corbin AT, Miles C, Cowan J, Hayes DG, Moore-Kucera J, Inglis DA (2013) Current and future prospects for biodegradable plastic mulch in certified organic production systems, eXtension Foundation, eOrganic Community of Practice 67951

Shogren RL, Hochmuth RC (2004) Field evaluation of watermelon grown on paperpolymerized vegetable oil mulches. HortScience 39:1588–1591

U.S. Dept. Agriculture (Agricultural Marketing Service) (2013) National Organic Program; Proposed Amendments to the National List of Allowed and Prohibited Substances (Crops and Processing; 7 CFR Part 205, Document Number AMS-NOP-13-011, NOP-13-01PR, RIN 0581-AD33). Fed Reg 78:52100–52107

ASTM International (2012) Standard specification for aerobically biodegradable plastics in soil environment (ASTM WK29802). West Conshohocken, PA

Siegenthaler KO, Kuenkel A, Skupin G, Yamamoto M (2012) Ecoflex and Ecovio: biodegradable, performance-enabling plastics. Adv Polym Sci 245:91–136

Kaseem M, Hamad K, Deri F (2012) Thermoplastic starch blends: a review of recent works. Polym Sci Ser A 54:165–176

Goldberger JR, Jones RE, Miles CA, Wallace RW, Inglis DA (2013) Barriers and bridges to the adoption of biodegradable plastic mulches for US specialty crop production. Renew Agric Food Sys 30:143–153

Miles C, Wallace R, Wszelaki A, Martin J, Cowan J, Walters T, Inglis DA (2012) Deterioration of potentially biodegradable alternative to black plastic mulch in three tomato production regions. HortScience 47:1270–1277

Cowan JS, Inglis DA, Miles C (2013) Deterioration of three potentially biodegradable plastic mulches before and after soil incorporation in a broccoli field production system in northwestern Washington. HortTechnology 23:6

Cowan JS, Miles C, Andrews PK, Inglis Debra A (2014) Biodegradable mulch performed comparable to polyethylene in high tunnel tomato (Solanum lycopersicum L.) production. J Sci Food Agric 94:1854–1864

Kijchavengkul T, Auras R, Rubino M, Alvarado E, Camacho Montero JR, Rosales JM (2010) Atmospheric and soil degradation of aliphatic-aromatic polyester films. Polym Degrad Stab 95:99–107

Kijchavengkul T, Auras R, Rubino M, Ngouajio M, Fernandez RT (2008) Assessment of aliphatic–aromatic copolyester biodegradable mulch films. Part II: laboratory simulated conditions. Chemosphere 71:1607–1616

Kijchavengkul T, Auras R, Rubino M, Ngouajio M, Fernandez RT (2008) Assessment of aliphatic–aromatic copolyester biodegradable mulch films. Part I: field study. Chemosphere 71:942–953

Wadsworth LC, Hayes DG, Wszelaki AL, Washington TL, Martin J, Lee J, Raley R, Pannell CT, Dharmalingam S, Miles C, Inglis DA, Saxton AM (2013) Evaluation of degradable spun–melt 100 % polylactic acid nonwovens mulch materials in a greenhouse envrionment. J Eng Fibers Fabr 8:50–59

Khan AYA, Wadsworth LC, Ryan CM (1995) Polymer-laid nonwovens from poly(lactide) resin. Int Nonwovens J 7:69–73

Dugan JS (2001) Novel properties of PLA fibers. Int Nonwovens J 10:29–33

Feng S, Jiao X (2011) The application of PLA resin on nonwovens production. Adv Mater Res (Durnten-Zurich, Switz.) 332–334:1239–1242

Li L, Zhang J, Li S, Qian X (2011) Research progress of elastic nonwovens with meltblown technology. Adv Mater Res (Durnten-Zurich, Switz.) 332–334:1247–1252

Rani A, Hussain A, Papnai N (2007) Non woven fabric construction. Synth Fibres 36:6–20

Endres H-J, Siebert-Raths A (2011) Engineering biopolymers—markets, manufacturing, properties and applications. Hsanser Publishers, Munich

Sodergard A, Stolt M (2010) Industrial production of high molecular weight poly(lactic acid). In: Auras R, Lim LT, Selke SEM, Tsuji H (eds) Poly(lactic acid): synthesis, structures, properties, processing, and applications. Wiley, Hoboken, pp 27–41

Kawai F (2010) Polylactic acid (PLA)-degrading microorganisms and PLA depolymerases. In: Cheng HN, Gross RA (eds) Green polymer chemistry: biocatalysis and biomaterials (ACS Symp. Series, Vol 1043). American Chemical Society, Washington, pp 405–414

Madhavan Nampoothiri K, Nair NR, John RP (2010) An overview of the recent developments in polylactide (PLA) research. Bioresour Technol 101:8493–8501

Tokiwa Y, Calabia BP, Ugwu CU, Aiba S (2009) Biodegradability of plastics. Int J Mol Sci 10:3722–3742

Karamanlioglu M, Robson GD (2013) The influence of biotic and abiotic factors on the rate of degradation of poly(lactic) acid (PLA) coupons buried in compost and soil. Polym Degrad Stab 98:2063–2071

Rudnik E, Briassoulis D (2011) Degradation behaviour of poly(lactic acid) films and fibres in soil under Mediterranean field conditions and laboratory simulations testing. Ind Crops Prod 33:648–658

Rudnik E, Briassoulis D (2011) Comparative biodegradation in soil behaviour of two biodegradable polymers based on renewable resources. J Polym Environ 19:18–39

Shi B, Palfery D (2010) Enhanced mineralization of PLA meltblown materials due to plasticization. J Polym Environ 18:122–127

Ji X, Miles C, Martin JT, Wallace RW, Wszelaki AL, Moore-Kucera J, Inglis DA, Lee J (2013) Effect of biodegradable mulches on environmental data collected from high tunnel and open field settings. HortScience 48:S335–S336

Martin JT (2013) The influence of organically managed high tunnel and open field production systems on strawberry (Fragaria × ananassa) quality and yield, tomato (Solanum lycopersicum) yield, and evaluation of plastic mulch alternatives (Masters Thesis). Plant Sci. University of Tennessee, Knoxville, TN

ASTM International (2013) Standard practice for operating xenon arc light apparatus for exposure of non-metallic materials (ASTM G155). West Conshohocken, PA

Hablot E, Dharmalingam S, Hayes DG, Wadsworth LC, Blazy C, Narayan R (2014) Effect of simulated weathering on physico-chemical properties and inherent biodegradation of PLA/PHA non-woven-based agricultural mulches. J Polym Environ 22:417–429

Li C, Moore-Kucera J, Miles C, Leonas K, Lee J, Corbin A, Inglis D (2014) Degradation of potentially biodegradable plastic mulch Films at three diverse U.S. locations. Agroecol Sustain Food Sys 38:861–889

ASTM International (2011) Standard test method for determining aerobic biodegradation of plastic materials under controlled composting conditions (ASTM D5338). West Conshohocken, PA

Müller RJ (2004) Biodegradability of polymers: regulations and methods for testing. In: Steinbüchel A (ed) General aspects and special applications (Biopolymers Series, Vol. 10). Wiley, Weinheim, pp 365–374

Kijchavengkul T, Auras R, Rubino M, Selke S, Ngouajio M, Fernandez RT (2010) Biodegradation and hydrolysis rate of aliphatic aromatic polyester. Polym Degrad Stab 95:2641–2647

Hu Y, Sato H, Zhang J, Noda I, Ozaki Y (2008) Crystallization behavior of poly(l-lactic acid) affected by the addition of a small amount of poly(3-hydroxybutyrate). Polymer 49:4204–4210

Weng Y-X, Wang L, Zhang M, Wang X-L, Wang Y-Z (2013) Biodegradation behavior of P(3HB,4HB)/PLA blends in real soil environments. Polym Test 32:60–70

Dharmalingam S (2014) Biodegradation and photodegradation of polylactic acid and polylactic acid/polyhydroxyalkanoate blends nonwoven agricultural mulches in ambient soil conditions (PhD Dissertation). Biosyst Eng. University of Tennessee, Knoxville, TN

Saito Y, Doi Y (1994) Microbial synthesis and properties of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) in Comamonas acidovorans. Int J Biol Macromol 16:99–104

Chandra R, Rustgi R (1998) Biodegradable polymers. Prog Polym Sci 23:1273–1335

ASTM International (2004) Standard test method for thickness of nonwoven fabrics (ASTM D5729). West Conshohocken, PA

ASTM International (2009) Standard test methods for mass per unit area (weight) of fabric (ASTM D3776/D3776 M). West Conshohocken, PA

ASTM International (2011) Standard test method for breaking force and elongation of textile fabrics (Strip Method; ASTM D5035). West Conshohocken, PA

Cowan JS (2013) The use of biodegradable mulch for tomato and broccoli production: crop yield and quality, mulch deterioration, and growers’ perception (PhD Dissertation). Horticulture, Washington State University, Pollman, WA

Kijchavengkul T, Auras R (2008) Compostability of polymers. Polym Int 57:793–804

Garlotta D (2002) A literature review of poly(lactic acid). J Polym Environ 9:63–84

Saito Y, Nakamura S, Hiramitsu M, Doi Y (1996) Microbial synthesis and properties of poly(3-hydroxybutyrate-co-4-hydroxybutyrate). Polym Int 39:169–174

Dagnon KL, Thellen C, Ratto JA, D’Souza NA (2010) Physical and thermal analysis of the degradation of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) coated paper in a constructed soil medium. J Polym Environ 18:510–522

Fischer EW, Sterzel HJ, Wegner G (1973) Investigation of the structure of solution grown crystals of lactide copolymers by means of chemicals reactions. Kolloid-Z Z Polym 251:980–990

Ahmed J, Varshney SK, Zhang J-X, Ramaswamy HS (2009) Effect of high pressure treatment on thermal properties of polylactides. J Food Eng 93:308–312

Nakamura S, Doi Y, Scandola M (1992) Microbial synthesis and characterization of poly(3-hydroxybutyrate-co-4-hydroxybutyrate). Macromolecules 25:4237–4241

Hakkarainen M, Karlsson S, Albertsson AC (2000) Rapid (bio)degradation of polylactide by mixed culture of compost microorganisms-low molecular weight products and matrix changes. Polymer 41:2331–2338

Acknowledgments

This research was funded through a grant from the NIFA Specialty Crops Research Initiative, USDA SCRI-SREP Grant Award No. 2009-02484. The authors thank Natureworks (Blair, NE, USA) and GreenBio (Tianjin, China) for donation of PLA (Ingeo™ 6202D) and PHA feedstocks, respectively. Dr. Arnold M. Saxton (Animal Sciences Dept., UT) assisted with the statistical analysis. Dr. Mark Radosevich [Biosystems Engineering and Soil Science (BESS) Dept., UT] provided facilities and expertise for the sterilization of soil, Experiment B. Dr. William Klingeman and Mr. Phil Flanagan (Plant Sciences Dept., UT) provided access and maintenance of the greenhouse used to conduct the experiment. Dr. Nicole Labbé and Ms. Lindsey Kline (Center for Renewal Carbon, UT) assisted with FTIR data collection. Drs. Elodie Hablot and Ramani Narayan (Chemical and Materials Engineering Dept., Michigan State University), provided facilities for the measurement of tensile strength for Experiment A. Mr. Rob Raley (BESS Dept., UT) assisted in collecting soil moisture and temperature.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dharmalingam, S., Hayes, D.G., Wadsworth, L.C. et al. Soil Degradation of Polylactic Acid/Polyhydroxyalkanoate-Based Nonwoven Mulches. J Polym Environ 23, 302–315 (2015). https://doi.org/10.1007/s10924-015-0716-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-015-0716-9