Abstract

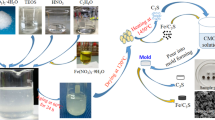

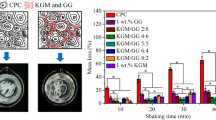

Anti-washout CaF2 stabilized C3S (F-C3S) bone cement was prepared by adding water-soluble carboxymethyl chitosan (CMCS) to the hydration liquid. The setting time, compressive strength and in vitro bioactivity of the CMCS modified F-C3S (CMCS–C3S) pastes were evaluated. The results indicate that CMCS–C3S pastes could be stable in the shaking simulated body fluid (SBF) after immediately mixed. The addition of CMCS significantly enhances the cohesion of particles, at the same time restrains the penetration of liquid, and thus endows the anti-washout ability. The setting times of the pastes increase with the increase of CMCS concentrations in the hydration liquid. Besides, the compressive strengths of CMCS–C3S pastes after setting for 1–28 days are lower than that of the pure F-C3S paste, but the sufficient strengths would be suitable for the clinical applications. The crystalline apatite deposited on the paste surface is retarded from 1 to 2 days for the addition of CMCS, but the quantities of deposited apatite are same after soaking in SBF for 3 days. As the result that pure C3S paste has shorter setting times than pure F-C3S paste, CMCS modified pure C3S pastes would have better anti-washout ability. Our study provides a convenient way to use C3S bone cement with excellent anti-washout ability when the pastes are exposed to biological fluids. The novel anti-washout CMCS–C3S bone cement with suitable setting times, sufficient strengths and in vitro bioactivity would have good prospects for medical application.

Similar content being viewed by others

References

Roberts HW, Toth JM, Berzins DW, Charlton DG. Mineral trioxide aggregate material use in endodontic treatment: a review of the literature. Dent Mater. 2008;24(2):149–64.

Exley C. A molecular mechanism of aluminium-induced Alzheimer’s disease? J Inorg Biochem. 1999;76(2):133–40.

Brook IM, Hatton PV. Glass-ionomers: bioactive implant materials. Biomaterials. 1998;19(6):565–71.

Al-Hezaimi K, Al-Shalan TA, Naghshbandi J, Simon JHS, Rotstein I. MTA preparations from different origins may vary in their antimicrobial activity. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2009;107(5):e85–8.

Zhao W, Wang J, Zhai W, Wang Z, Chang J. The self-setting properties and in vitro bioactivity of tricalcium silicate. Biomaterials. 2005;26(31):6113–21.

Zhao W, Chang J. Two-step precipitation preparation and self-setting properties of tricalcium silicate. Mater Sci Eng. 2007;28(2):289–93.

Zhao W, Chang J. Sol-gel synthesis and in vitro bioactivity of tricalcium silicate powders. Mater Lett. 2004;58(19):2350–3.

Zhao W, Chang J, Wang J, Zhai W, Wang Z. In vitro bioactivity of novel tricalcium silicate ceramics. J Mater Sci Mater Med. 2007;18(5):917–23.

Lin Q, Li Y, Lan X, Lu C, Chen Y, Xu Z. The apatite formation ability of CaF2 doping tricalcium silicates in simulated body fluid. Biomed Mater. 2009;4:045005.

Lin Q, Li Y, Lan X, Lu C, Xu Z. The Effect of CaF2 on the preparation and in vitro bioactivity of tricalcium silicates. Chin J Inorg Chem. 2008;24(12):1937–42.

Christodoulou I, Buttery LD, Saravanapavan P, Tai G, Hench LL, Polak JM. Dose- and time-dependent effect of bioactive gel-glass ionic-dissolution products on human fetal osteoblast-specific gene expression. J Biomed Mater Res B Appl Biomater. 2005;74B(1):529–37.

Laurent P, Camps J, De Meo M, Dejou J, About I. Induction of specific cell responses to a Ca3SiO5-based posterior restorative material. Dent Mater. 2008;24(11):1486–94.

Gandolfi MG, Pagani S, Perut F, Ciapetti G, Baldini N, Mongiorgi R, Prati C. Innovative silicate-based cements for endodontics: a study of osteoblast-like cell response. J Biomed Mater Res. 2008;87A(2):477–86.

Hench LL. Genetic design of bioactive glass. J Eur Ceram Soc. 2008;29(7):1257–65.

Ishikawa K, Miyamoto Y, Kon M, Nagayama M, Asaoka K. Non-decay type fast-setting calcium phosphate cement: composite with sodium alginate. Biomaterials. 1995;16(7):527–32.

Kai D, Li D, Zhu X, Zhang L, Fan H, Zhang X. Addition of sodium hyaluronate and the effect on performance of the injectable calcium phosphate cement. J Mater Sci Mater Med. 2009;20(8):1595–602.

Zhiguang Huan JC. Novel tricalcium silicate/monocalcium phosphate monohydrate composite bone cement. J Biomed Mater Res. 2007;82B:352–9.

Wang X, Sun H, Chang J. Characterization of Ca3SiO5/CaCl2 composite cement for dental application. Dent Mater. 2008;24(1):74–82.

Huan Z, Chang J. Effect of sodium carbonate solution on self-setting properties of tricalcium silicate bone cement. J Biomater Appl. 2008;23(3):247–62.

Huan Z, Chang J. Study on physicochemical properties and in vitro bioactivity of tricalcium silicate-calcium carbonate composite bone cement. J Mater Sci Mater Med. 2008;19(8):2913–8.

Kunio I, Miyamoto Y, Takechi M. Non-decay type fast-setting calcium phosphate cement: hydroxyapatite putty containing an increased amount of sodium alginate. J Biomed Mater Res. 1997;36(3):393–9.

Xiupeng W, Ling C, Hong X, Jiandong Y. Influence of anti-washout agents on the rheological properties and injectability of a calcium phosphate cement. J Biomed Mater Res. 2007;81B(2):410–8.

Takagi S, Chow LC, Hirayama S, Eichmiller FC. Properties of elastomeric calcium phosphate cement-chitosan composites. Dent Mater. 2003;19(8):797–804.

Cherng A, Takagi S, Chow LC. Effects of hydroxypropyl methylcellulose and other gelling agents on the handling properties of calcium phosphate cement. J Biomed Mater Res. 1997;35(3):273–7.

Shirosaki Y, Tsuru K, Hayakawa S, Osaka A, Lopes MA, Santos JD, Costa MA, et al. Physical, chemical and in vitro biological profile of chitosan hybrid membrane as a function of organosiloxane concentration. Acta Biomater. 2009;5(1):346–55.

Lee EJ, Shin DS, Kim HE, Kim HW, Koh YH, Jang JH. Membrane of hybrid chitosan-silica xerogel for guided bone regeneration. Biomaterials. 2009;30(5):743–50.

Muzzarelli RAA, Mattioli-Belmonte M, Tietz C, Biagini R, Ferioli G, Brunelli MA, Fini M, et al. Stimulatory effect on bone formation exerted by a modified chitosan. Biomaterials. 1994;15(13):1075–81.

Kokubo T, Takadama H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials. 2006;27(15):2907–15.

Shozo T, Laurence CC, Satoshi H, Akiyoshi S. Premixed calcium-phosphate cement pastes. J Biomed Mater Res. 2003;67B(2):689–96.

Lin Y, Chen Q, Luo H. Preparation and characterization of N-(2-carboxybenzyl)chitosan as a potential pH-sensitive hydrogel for drug delivery. Carbohydr Res. 2007;342(1):87–95.

Coleman NJ, Awosanya K, Nicholson JW. Aspects of the in vitro bioactivity of hydraulic calcium (alumino) silicate cement. J Biom Mater Res. 2008;90 A(1):166–74.

Peitl O, Dutra Zanotto E, Hench LL. Highly bioactive P2O5–Na2O–CaO–SiO2 glass-ceramics. J Non-Crystal Solids. 2001;292(1–3):115–26.

Wang X, Ma J, Wang Y, He B. Structural characterization of phosphorylated chitosan and their applications as effective additives of calcium phosphate cements. Biomaterials. 2001;22(16):2247–55.

Rau JV, Generosi A, Smirnov VV, Ferro D, Rossi Albertini V, Barinov SM. Energy dispersive X-ray diffraction study of phase development during hardening of calcium phosphate bone cements with addition of chitosan. Acta Biomater. 2008;4(4):1089–94.

Chen L, Tian Z, Du Y. Synthesis and pH sensitivity of carboxymethyl chitosan-based polyampholyte hydrogels for protein carrier matrices. Biomaterials. 2004;25(17):3725–32.

Lin YH, Liang HF, Chung CK, Chen MC, Sung HW. Physically crosslinked alginate/N, O-carboxymethyl chitosan hydrogels with calcium for oral delivery of protein drugs. Biomaterials. 2005;26(14):2105–13.

Mollah MYA, Yu W, Schennach R, Cocke DL. A Fourier transform infrared spectroscopic investigation of the early hydration of Portland cement and the influence of sodium lignosulfonate. Cem Con Res. 2000;30(2):267–73.

O’Kelly K, Tancred D, McCormack B, Carr A. A quantitative technique for comparing synthetic porous hydroxyapatite structures and cancellous bone. J Mater Sci: Mater Med. 1996;7(4):207–13.

Ramila A, Vallet-Regi M. Static and dynamic in vitro study of a sol-gel glass bioactivity. Biomaterials. 2001;22(16):2301–6.

Yoshitsugu F, Takao Y, Takashi N, Seiya K, Chikara O, Tadashi K. The bonding behavior of calcite to bone. J Biomed Mater Res. 1991;25(8):991–1003.

Takechi M, Miyamoto Y, Ishikawa K, Yuasa M, Nagayama M, Kon M, Asaoka K. Non-decay type fast-setting calcium phosphate cement using chitosan. J Mater Sci Mater Med. 1996;7(6):317–22.

Chen CC, Lai MH, Wang WC, Ding SJ. Properties of anti-washout-type calcium silicate bone cements containing gelatin. J Mater Sci Mater Med. 2010;21(4):1057–68.

Takechi M, Miyamoto Y, Ishikawa K, Toh T, Yuasa T, Nagayama M, Suzuki K. Initial histological evaluation of anti-washout type fast-setting calcium phosphate cement following subcutaneous implantation. Biomaterials. 1998;19(22):2057–63.

Acknowledgments

This work is financially supported by the National Basic Research Program of China (973 Program) (2009CB623105), National Natural Science Foundation of China (50802042), Natural Science Foundation of Jiangsu province, China (BK2008379), Science and Technology Developing Foundation of Nanjing (ZKX07016), State Key Laboratory of Materials-Oriented Chemical Engineering (KL09-6) and Graduate Innovation Foundation of Jiangsu Province (CX09B-127Z).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Lin, Q., Lan, X., Li, Y. et al. Anti-washout carboxymethyl chitosan modified tricalcium silicate bone cement: preparation, mechanical properties and in vitro bioactivity. J Mater Sci: Mater Med 21, 3065–3076 (2010). https://doi.org/10.1007/s10856-010-4160-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-010-4160-z