Abstract

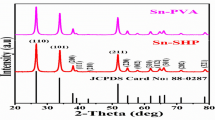

Pure and Sm-doped In2O3 porous nanotubes have been successfully fabricated by the single-capillary electrospinning method followed by calcination. The as-synthesized porous nanotubes were investigated by X-ray powder diffraction (XRD), energy-dispersive X-ray (EDX), scanning electron microscope (SEM), Raman spectra and X-ray photoelectron spectroscopy (XPS). It can be seen in SEM images that the surface of nanotubes is distributed with numerous pores. Gas sensing investigation reveals that Sm-doped In2O3 porous nanotubes possess high-performance formaldehyde sensing properties. The response of gas sensors based on Sm-doped In2O3 porous nanotubes was 54.37 towards 100 ppm formaldehyde at 240 °C, which was 5 times larger than that of pure In2O3 porous nanotubes (10.87). The response and recovery times to 100 ppm formaldehyde were 9 and 40 s, respectively. Moreover, even at low concentration of 100 ppb formaldehyde, a detectable response of 2.1 can be observed. Furthermore, Sm-doped In2O3 porous nanotube gas sensors have excellent selectivity to formaldehyde.

Similar content being viewed by others

References

Q. Zhao, L. Ma, Q. Zhang, C. Wang, X. Xu, J. Nanomater. 2015, 1 (2015). doi:10.1155/2015/850147

L.I. Hernández, R. Godin, J.J. Bergkamp et al., J. Phys. Chem. B 117, 4568 (2013). doi:10.1021/jp3086792

X. Li, H. Zhang, C. Feng et al., RSC Adv. 4, 27552 (2014). doi:10.1039/c4ra03307h

Q. Qi, P.-P. Wang, J. Zhao et al., Sens. Actuators B: Chem. 194, 440 (2014). doi:10.1016/j.snb.2013.12.115

Z. Wang, Z. Li, T. Jiang, X. Xu, C. Wang, ACS Appl. Mater. Interfaces 5, 2013 (2013). doi:10.1021/am3028553

J. Gao, L. Wang, K. Kan et al., J. Mater. Chem. A 2, 949 (2014). doi:10.1039/c3ta13943c

P.-J. Yao, J. Wang, Q. Qiao, H.-Y. Du, J. Mater. Sci. 50, 1338 (2014). doi:10.1007/s10853-014-8694-1

A. Chaudhary, S. Hellweg, Environ. Sci. Technol. 48, 14607 (2014). doi:10.1021/es5045024

A. Afkhami, H. Bagheri, T. Madrakian, Desalination 281, 151 (2011). doi:10.1016/j.desal.2011.07.052

A. Afkhami, H. Bagheri, Microchim. Acta 176, 217 (2011). doi:10.1007/s00604-011-0715-z

C. Bosetti, J.K. McLaughlin, R.E. Tarone, E. Pira, C. La Vecchia, Ann. Oncol. 19, 29 (2007). doi:10.1093/annonc/mdm202

T. Guo, Y. Luo, Y. Zhang, Y.-H. Lin, C.-W. Nan, J. Appl. Phys. 116, 044309 (2014). doi:10.1063/1.4890938

C. Zhao, W. Hu, Z. Zhang, J. Zhou, X. Pan, E. Xie, Sens. Actuators B: Chem. 195, 486 (2014). doi:10.1016/j.snb.2014.01.084

W. Li, L.-S. Zhang, Q. Wang et al., J. Mater. Chem. 22, 15342 (2012). doi:10.1039/c2jm32031b

W. Tang, J. Wang, P. Yao, X. Li, Sens. Actuators B: Chem. 192, 543 (2014). doi:10.1016/j.snb.2013.11.003

L xu, B Dong, Y Wang, et al. (2010) Journal of Physical Chemstry C 114: 7

L. Wang, X. Xu, Ceram. Int. 41, 7687 (2015). doi:10.1016/j.ceramint.2015.02.097

S. Xu, J. Gao, L. Wang et al., Nanoscale 7, 14643 (2015). doi:10.1039/c5nr03796d

C. Zhao, B. Huang, E. Xie, J. Zhou, Z. Zhang, Sens. Actuators B: Chem. 207, 313 (2015). doi:10.1016/j.snb.2014.10.087

C. Liu, X. Chi, X. Liu, S. Wang, J. Alloy. Compd. 616, 208 (2014). doi:10.1016/j.jallcom.2014.07.112

M. Tiemann, Chem. —Eur. J. 13, 8376 (2007). doi:10.1002/chem.200700927

Y.-B. Zhang, J. Yin, L. Li, L.-X. Zhang, L.-J. Bie, Sens. Actuators B: Chem. 202, 500 (2014). doi:10.1016/j.snb.2014.05.111

H.-Q. Wang, M. Batentschuk, A. Osvet, L. Pinna, C.J. Brabec, Adv. Mater. 23, 2675 (2011). doi:10.1002/adma.201100511

H.T. Giang, H.T. Duy, P.Q. Ngan et al., Sens. Actuators B: Chem. 158, 246 (2011). doi:10.1016/j.snb.2011.06.013

L. Liu, C. Liu, S. Li et al., Sens. Actuators B: Chem. 177, 893 (2013). doi:10.1016/j.snb.2012.11.106

G.F. Pérez-Sánchez, F. Chávez, D. Cortés-Salinas et al., Vacuum 107, 236 (2014). doi:10.1016/j.vacuum.2014.02.012

L.X. Zhang, Y.C. Zhang, M. Zhang, Mater. Chem. Phys. 118, 223 (2009). doi:10.1016/j.matchemphys.2009.07.047

A. Singhal, S.N. Achary, J. Manjanna, O.D. Jayakumar, R.M. Kadam, A.K. Tyagi, J. Phys. Chem. C 113, 3600 (2009). doi:10.1016/j.snb.2015.04.083

D. Han, P. Song, S. Zhang, H. Zhang, Q. Xu, Q. Wang, Sens. Actuators B: Chem. 216, 488 (2015). doi:10.1016/j.snb.2015.04.083

B.T. Sone, E. Manikandan, A. Gurib-Fakim, M. Maaza, J. Alloy. Compd. 650, 357 (2015). doi:10.1016/j.jallcom.2015.07.272

C. Dong, X. Liu, B. Han, S. Deng, X. Xiao, Y. Wang, Sens. Actuators B: Chem. 224, 193 (2016). doi:10.1016/j.snb.2015.09.107

H. Ren, W. Zhao, L. Wang, S.O. Ryu, C. Gu, J. Alloy. Compd. 653, 611 (2015). doi:10.1016/j.jallcom.2015.09.065

Y. Lin, W. Wei, Y. Li et al., J. Alloy. Compd. 651, 690 (2015). doi:10.1016/j.jallcom.2015.08.174

C. Dong, Q. Li, G. Chen, X. Xiao, Y. Wang, Sens. Actuators B: Chem. 220, 171 (2015). doi:10.1016/j.snb.2015.05.056

H. Shan, C. Liu, L. Liu et al., Sens. Actuators B: Chem. 184, 243 (2013). doi:10.1016/j.snb.2013.04.088

X. Chi, C. Liu, L. Liu et al., Mater. Sci. Semicond. Process. 18, 160 (2014). doi:10.1016/j.mssp.2013.11.016

G.X. Wan, S.Y. Ma, X.W. Sun et al., Mater. Lett. 145, 48 (2015). doi:10.1016/j.matlet.2015.01.085

L. Xu, H. Song, B. Dong, Y. Wang, J. Chen, X. Bai, Inorg. Chem. 49, 10590 (2010). doi:10.1021/ic101602a

G.-Y. Adachi, N. Imanaka, Chem. Rev. 98, 36 (1998)

C. Li, C. Feng, F. Qu et al., Sens. Actuators B: Chem. 207, 90 (2015). doi:10.1016/j.snb.2014.10.035

Acknowledgments

The work has been supported by the Jilin Provincial Science and Technology Department (No. 20140204027GX).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, C., Wang, X., Xie, F. et al. Fabrication of Sm-doped porous In2O3 nanotubes and their excellent formaldehyde-sensing properties. J Mater Sci: Mater Electron 27, 9870–9876 (2016). https://doi.org/10.1007/s10854-016-5055-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5055-7