Abstract

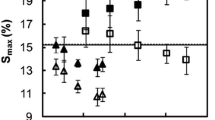

Thermal modification of wood results in improved dimensional stability and increases the end-use possibilities of wood. Modification under saturated steam is reported to result in higher performance when compared to more traditional thermal modification methods. This study analyses the chemical and ultrastructural changes, as well as water vapour sorption properties of Scots pine modified thermally in a high-pressure reactor under saturated steam. The aim is to reveal important chemical and sorption-related changes in wood modified under saturated steam. Chemical composition, water vapour sorption properties, accessibility and concentration of cellulosic hydroxyl groups, as well as evolution of cell wall are discussed. At a temperature of 180 °C, clear cell wall delamination and distortion were observed. In nanoscale, the results indicated opening of microfibril bundles, which leads to higher surface area and theoretically, a higher accessibility. However, a decrease in the equilibrium moisture content and accessibility of both extracted and unextracted samples were observed, but the decrease was less obvious in extracted samples.Hence, it was concluded that extractives and degradation products play an important role during thermal modification by blocking porosity and therefore decreasing accessibility and reducing sorption of thermally modified samples. The changes in hysteresis behaviour after extraction also support this outcome.

Similar content being viewed by others

References

Hill CAS (2007) Wood modification: chemical, thermal and other processes, 2nd edn. Wiley, Chischester

Navi P, Sandberg D (2012) Thermo-hydro-mechanical wood processing, 1st edn. CRC Press, Lausanne

Sandberg D, Kutnar A (2016) Thermally modified timber: recent developments in Europe and North America. Wood Fiber Sci 48:28–39

Boonstra MJ, Tjeerdsma B (2006) Chemical analysis of heat treated softwoods. Holz Roh Werkst 64(3):204–211

Boonstra MJ, Van Acker J, Tjeerdsma B, Kegel EV (2007) Strength properties of thermally modified softwoods and its relation to polymeric structural wood constituents. Ann For Sci 64:679–690. doi:10.1051/forest:2007048

Esteves B, Pereira H (2009) Wood modification by heat treatment: a review. BioResources 4(1):370–404

Willems W (2009) A novel economic large-scale production technology for high-quality thermally modified wood. In: European conference on wood modification. Stockholm, pp 31–35

Sivonen H, Maunu SL, Sundholm F, Jämsä S, Viitaniemi P (2002) Magnetic resonance studies of thermally modified wood. Holzforschung 56(6):648–654

Nuopponen M, Vuorinen T, Jämsä S, Viitaniemi P (2005) Thermal modifications in softwood studied by FT-IR and UV resonance raman spectroscopies. J Wood Chem Technol 24(1):13–26. doi:10.1081/WCT-120035941

Bourgois J, Guyonnet R (1988) Characterization and analysis of torrefied wood. Wood Sci Technol 22:143–155

Windeisen E, Strobel C, Wegener G (2007) Chemical changes during the production of thermo-treated beech wood. Wood Sci Technol 41(6):523–536. doi:10.1007/s00226-007-0146-5

Alén R, Kotilainen R, Zaman A (2002) Thermochemical behavior of Norway spruce (Picea abies) at 180–225 °C. Wood Sci Technol 36:163–171. doi:10.1007/s00226-001-0133-1

Brito JO, Silva FG, Leão MM, Almeida G (2008) Chemical composition changes in eucalyptus and pinus woods submitted to heat treatment. Bioresour Technol 99:8545–8548. doi:10.1016/j.biortech.2008.03.069

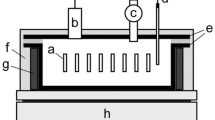

Rautkari L, Honkanen J, Hill CAS, Ridley-Ellis D, Hughes M (2014) Mechanical and physical properties of thermally modified Scots pine wood in high pressure reactor under saturated steam at 120, 150 and 180 °C. Eur J Wood Wood Prod 72(1):33–41. doi:10.1007/s00107-013-0749-5

Tjeerdsma BF, Boonstra MJ, Militz H (1998) Thermal modification of non-durable wood species. 2. Improved wood properties of thermally treated wood. International Research Group on Wood Preservation, Document no. IRG/WP, 98-40124. http://www.irg-wp.com/irgdocs/details.php?928f2680-9e22-45f9-b0a1-0ddd090af5f0. Accessed 8 Dec 2015

Militz H (2002) Thermal treatment of wood: European processes and their background, Document no. IRG/WP40241

Wikberg H, Maunu SL (2004) Characterisation of thermally modified hard- and softwoods by 13C CPMAS NMR. Carbohydr Polym 58(4):461–466

Bhuiyan MTR, Hirai N (2005) Study of crystalline behavior of heat-treated wood cellulose during treatments in water. J Wood Sci 51:42–47

Hill CAS, Ramsay J, Keating B, Laine K, Rautkari L, Hughes M, Constant B (2012) The water vapour sorption properties of thermally modified and densified wood. J Mater Sci 47:3191–3197. doi:10.1007/s10853-011-6154-8

Bhuiyan MTR, Hirai N, Sobue N (2000) Changes of crystallinity in wood cellulose by heat treatment under dried and moist conditions. J Wood Sci 46(6):431–436

Dwianto W, Tanaka F, Inoue M, Norimoto M (1996) Crystallinity changes of wood by heat or steam treatment. Wood Res Bull Wood Res Inst Kyoto Univ 83:47–49

Guo J, Song K, Salmén L, Yin Y (2015) Changes of wood cell walls in response to hygro-mechanical steam treatment. Carbohydr Polym 115:207–214

Suchy M, Virtanen J, Kontturi E, Vuorinen T (2010) Impact of drying on wood ultrastructure observed by deuterium exchange and photoacoustic FT-IR spectroscopy. Biomacromolecules 11:515–520

Borrega M, Kärenlampi PP (2010) Hygroscopicity of heat-treated Norway spruce (Picea abies) wood. Eur J Wood Wood Prod 68(2):233–235. doi:10.1007/s00107-009-0371-8

Borrega M, Kärenlampi PP (2008) Mechanical behavior of heat-treated spruce (Picea abies) wood at constant moisture content and ambient humidity. Holz Roh Werkst 66(1):63–69. doi:10.1007/s00107-007-0207-3

Hill CAS, Norton AJ, Newman G (2010) The water vapour sorption properties of Sitka spruce determined using a dynamic vapour sorption apparatus. Wood Sci Technol 44:497–514. doi:10.1007/s00226-010-0305-y

Rautkari L, Hill CAS, Curling S, Jalaludin Z, Ormondroyd G (2013) What is the role of the accessibility of wood hydroxyl groups in controlling moisture content? J Mater Sci 48(18):6352–6356. doi:10.1007/s10853-013-7434-2

Xie Y, Hill CAS, Jalaludin Z, Curling SF, Anandijwala RD, Norton AJ, Newman G (2011) The dynamic vapour sorption behaviour of natural fibres and kinetic analysis ysing the parallel exponential kinetics model. J Mater Sci 46(2):479–489. doi:10.1007/s10853-010-4935-0

Kamdem DP, Pizzi A, Jermannaud A (2002) Durability of heat-treated wood. Holz Roh Werkst 60(1):1–6

Gonzalez-Peña MM, Breese MC, Hill CAS (2004) Hygroscopicity in heat-treated wood: effect of extractives. In: Proceedings of ICECFOP1: 1st international conference on environmentally compatible forest products, pp 105–119

Rousset P, Lapierre C, Pollet B, Quirino W, Perre P (2009) Effect of severe thermal treatment on spruce and beech wood lignins. Ann For Sci 66(1):110. doi:10.1051/forest/2008078

Nuopponen M, Vuorinen T, Jämsä S, Viitaniemi P (2003) The effects of a heat treatment on the behaviour of extractives in softwood studied by FTIR spectroscopic methods. Wood Sci Technol 37(2):109–115

Esteves B, Graça J, Pereira H (2008) Extractive composition and summative chemical analysis of thermally treated eucalypt wood. Holzforschung 62(3):344–351

Manninen A, Pasanen P, Holopainen J (2002) Comparing the VOC emissions between air-dried and heat-treated Scots pine wood. Atmos Environ 36:1763–1768

Fengel D, Wegener G (1984) Wood: chemistry, ultrastructure, reactions. Walter de Gruyter Co, Berlin

Prins MJ, Ptasinski KJ, Janssen FJJG (2006) Torrefaction of wood Part 1. Weight loss kinetics. J Anal Appl Pyrolysis 77:28–34

Boonstra MJ, Rijsdijk JF, Sander C, Kegel E, Tjeerdsma B, Militz H, van Acker J, Stevens M (2006) Microstructural and physical aspects of heat treated wood. Part 1. Softwoods Maderas Cienc Tecnol 8(3):193–208

Hietala S, Maunu SL, Sundholm F, Jämsä S, Viitaniemi P (2002) Structure of thermally modified wood studied by liquid state NMR measurements. Holzforschung 56(5):522–528

Zauer M, Hempel S, Pfriem A, Mechtcherine V, Wagenführ A (2014) Investigations of the pore-size distribution of wood in the dry and wet state by means of mercury intrusion porosimetry. Wood Sci Technol 48(6):1229–1240. doi:10.1007/s00226-014-0671-y

Pizzi A, Stephanou A, Boonstra MJ, Pendlebury AJ (1994) A new concept on the chemical modification of wood by organic anhydrides. Holzforschung 48:91–94

Ismadji S, Sudaryanto Y, Hartono SB, Setiawan LEK, Ayucitra A (2005) Activated carbon from char obtained from vacuum pyrolysis of teak sawdust: pore structure development and characterization. Bioresour Technol 96:1364–1369

Pönni R, Rautkari L, Hill CAS, Vuorinen T (2014) Accessibility of hydroxyl groups in birch kraft pulps quantified by deuterium exchange in D2O vapor. Cellulose 21:1217–1226

Kymäläinen M, Rautkari L, Hill CAS (2015) Sorption behaviour of torrefied wood and charcoal determined by dynamic vapour sorption. J Mater Sci 50:7673–7680. doi:10.1007/s10853-015-9332-2

Hill CAS, Norton A, Newman G (2009) The water vapor sorption behavior of natural fibers. J Appl Polym Sci 112:1524–1537

Jalaludin Z, Hill CAS, Xie Y, Samsi HW, Husain H, Awang K, Curling SF (2010) Analysis of the water vapour sorption isotherms of thermally modified acacia and sesendok. Wood Materi Sci Eng 5(3–4):194–203

Penttilä PA, Kilpeläinen P, Tolonen L, Suuronen J-P, Sixta H, Willför S, Serimaa R (2013) Effects of pressurized hot water extraction on the nanoscale structure of birch sawdust. Cellulose 20:2335–2347

Virtanen T, Penttilä PA, Maloney TC, Grönqvist S, Kamppuri T, Vehviläinen M, Serimaa R, Maunu SL (2015) Impact of mechanical and enzymatic pretreatments on softwood fibre wall structure studied with NMR spectroscopy and X-ray scattering. Cellulose 22:1565–1576

Leppänen K, Andersson S, Torkkeli M, Knaapila M, Kotelnikova N, Serimaa R (2009) Structure of cellulose and microcrystalline cellulose from various wood species, cotton and flax studied by X-ray scattering. Cellulose 16:999–1015

Altgen M, Willems W, Militz H (2015) Wood degradation affected by process conditions during thermal modification of European beech in a high-pressure reactor system. Eur J Wood Prod 74(5):653–662

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest regarding this work.

Rights and permissions

About this article

Cite this article

Kymäläinen, M., Ben Mlouka, S., Belt, T. et al. Chemical, water vapour sorption and ultrastructural analysis of Scots pine wood thermally modified in high-pressure reactor under saturated steam. J Mater Sci 53, 3027–3037 (2018). https://doi.org/10.1007/s10853-017-1714-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1714-1