Abstract

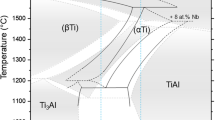

Ti alloys are successfully applied in several sectors due to their outstanding properties. A greater increase in the industrial consumption of Ti is strongly limited by its cost, which is mainly related to difficulties in obtaining products with specific geometries. The use of thixoforming processes to form Ti alloys represents an innovative approach to minimizing such difficulties. The objectives of this study were to select and produce binary Ti–Cu alloys specifically designed for thixoforming and to investigate their microstructure when heated to the semisolid state. Specific compositions were chosen according to the criteria for thixoformability, such as the solidification range and the sensitivity of the liquid fraction to temperature. Samples of these alloys were prepared by arc melting and were then hot forged prior to partial melting. The results obtained by thermal analysis and thermodynamic simulation were in good agreement and indicated that Ti–Cu alloys can be processed by thixoforming at temperatures below 1100 °C. Microstructural characterization showed fine and globular microstructures in the semisolid state, revealing the promising potential of Ti–Cu alloys as thixoformable materials.

Similar content being viewed by others

References

Lütjering G, Williams JC (2003) Titanium. Springer, Berlin

Flemings MC (1991) Behavior of metal alloys in the semisolid state. Metall Trans A22:957–981

Kapranos P, Ward PJ, Atkinson HV, Kirkwood DH (2000) Near net shaping by semi-solid metal processing. Mater Des 21:387–394

Omar MZ, Atkinson HV, Howe AA, Palmiere EJ, Kapranos P, Ghazali MJ (2009) Solid–liquid structural break-up in M2 tool steel for semi-solid metal processing. J Mater Sci 44:869–874. doi:10.1007/s10853-008-3181-1

Amin-Ahmadi B, Aashuri H (2010) Semisolid structure for M2 high speed steel prepared by cooling slope. J Mater Process Technol 210:1632–1635

Omar MZ, Alfan A, Syarif J, Atkinson HV (2011) Microstructural investigations of XW-42 and M2 tool steels in semi-solid zones via direct partial remelting route. J Mater Sci 46:7696–7705. doi:10.1007/s10853-011-5749-4

Zhao C, Song R (2014) Evolution of microstructure and mechanical properties for 9Cr18 stainless steel during thixoforming. Mater Des 59:502–508

Gu G, Pesci R, Langlois L, Becker E, Bigot R (2015) Microstructure investigation and flow behavior during thixoextrusion of M2 steel grade. J Mater Process Technol 216:178–187

Ramadan M, Nomura H (2005) Flow analysis of semi solid processing for grey cast iron. Int J Cast Metal Res 18:266–272

Roca AS, Fals HDC, Pedron JA, Zoqui EJ (2012) Thixoformability of hypoeutectic gray cast iron. J Mater Process Technol 212:1225–1235

Zhao YQ, Wu WL, Ma XD, Chang H, Yang HY, Wu H, Feng L (2004) Semi-solid oxidation and deformation behavior of Ti14 alloy. Mater Sci Eng A 373:315–319

Zhao YQ, Wu WL, Chang H (2006) Research on microstructure and mechanical properties of new α + Ti2Cu alloy after semi-solid deformation. Mater Sci Eng A 416:181–186

Chen YN, Wei JF, Zhao YQ (2009) Compressive deformation and forging behavior of Ti14 alloy in semi-solid state. Mater Sci Eng A 520:16–22

Chen YN, Wei JF, Zhao YQ, Sun J (2009) Effect of semi-solid forging temperature on microstructure and mechanical properties of Ti14 alloy. J Alloys Compd 487:314–320

Chen YN, Wei JF, Zhao YQ, Zheng J (2011) Microstructure evolution and grain growth behavior of Ti14 alloy during semi-solid isothermal process. Trans Nonferrous Metal Soc 21:1018–1022

Chen YN, Wei JF, Zhao YQ, Ma X, Hao J (2012) Microscopic characterization of semi-solid Ti14 alloy. Rare Metal Mater Eng 41:581–584

Chen YN, Liu G, Zhang XM, Zhao YQ (2013) Influence of semisolid forging ratio on the microstructure and mechanical properties of Ti14 alloy. Int J Miner Met Mater 20:266–272

Liu D, Atkinson HV, Jones H (2005) Thermodynamic prediction of thixoformability in alloys based on the Al-Si-Cu and Al-Si-Cu-Mg systems. Acta Mater 53:3807–3819

Camacho AM, Atkinson HV, Kapranos P, Argent BB (2003) Thermodynamic predictions of wrought alloy compositions amenable to semi-solid processing. Acta Mater 51:2319–2330

Han Q, Viswanathan S (2004) The use of thermodynamic simulation for the selection of hypoeutectic aluminum-silicon alloys for semi-solid metal processing. Mater Sci Eng A 364:48–54

Li YD, Apelian D, Xing B, Ma Y, Hao Y (2010) Commercial AM60 alloy for semisolid processing: alloy optimization and thermodynamic analysis. Trans Nonferrous Metal Soc 20:1572–1578

Liu YQ, Das A, Fan Z (2004) Thermodynamic predictions of Mg-Al-M (M = Zn, Mn, Si) alloy compositions amenable to semisolid metal processing. Mater Sci Technol 20:35–41

Baker H (1992) ASM handbook. Alloy phase diagrams, vol 3. ASM International, Ohio

Djurdjevic MB, Schmid-Fetzer R (2006) Thermodynamic calculation as a tool for thixoforming alloy and process development. Mater Sci Eng A 417:24–33

Hari Kumar KC, Ansara I, Wollants P, Delaey L (1996) Thermodynamic optimization of the Cu-Ti system. Z Metallkunde 87:666–672

Li C, Wang H, Wu S, Xu L, Wang K, Fu H (2010) Research on mould filling and solidification of titanium alloy in vertical centrifugal casting. Rare Metal Mater Eng 39:388–392

Eskin DG, Suyitno KL (2004) Mechanical properties in the semi-solid state and hot tearing of aluminium alloys. Prog Mater Sci 49:628–711

Okamoto H (2002) Cu-Ti (Copper-Titanium). J Phase Equilib 23:549–550

Schulson EM (1977) Electron channeling patterns in scanning electron microscopy. J Mater Sci 12:1071–1087. doi:10.1007/BF02426843

Zaefferer S, Elhami NN (2014) Theory and application of electron channeling contrast imaging under controlled diffraction conditions. Acta Mater 75:20–50

Zoqui EJ, Robert MH (2001) Contribution to the study of mechanisms involved in the formation of rheocast structure. J Mater Process Technol 109:215–219

Banerjee S, Mukhopadhyay P (2007) Phase transformations: examples of titanium and zirconium alloys. Elsevier, Oxford

Hirt G, Kopp R (2009) Thixoforming: semi solid metal processing. Wiley, Weinhein

Acknowledgements

The authors thank the Brazilian research agencies FAPESP (State of São Paulo Research Foundation), CNPq (National Council for Scientific and Technological Development), and CAPES (Federal Agency for the Support and Evaluation of Graduate Education) for their financial support. We are also indebted to Villares Metals, which gently donated the high-chemical-purity Cu to this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Campo, K.N., de Lima, D.D., Lopes, É.S.N. et al. On the selection of Ti–Cu alloys for thixoforming processes: phase diagram and microstructural evaluation. J Mater Sci 50, 8007–8017 (2015). https://doi.org/10.1007/s10853-015-9367-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9367-4