Abstract

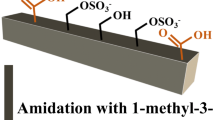

In this paper, we studied the hydrophobization of TEMPO-oxidized cellulose gel (TOCgel) by covalent coupling of long carbon chains via esterification and amidation processes. In this context, amidation process was achieved by covalent coupling of stearylamine (SA) on the carboxyl moieties of TOCgel using carbodiimide and hydroxysuccimide as catalyst and amidation agent. In parallel, esterification process was realized by grafting of alkyl ketene dimer (AKD) on the hydroxyl groups of TOCgel in the presence of 1-methylimidazole as a promoter. The grafting state of the final products obtained under heterogeneous conditions was confirmed by fourier transform infrared spectroscopy (FTIR), X-ray photoelectron spectroscopy (XPS), thermogravimetric analysis (TGA), transmission and scanning electron microscopy, and contact angle measurement (CAM). The hydrophobic behavior of the obtained products was discussed based on the results of CAM and absorption rate of water drop in their film surface. FTIR and XPS results indicated the formation of amide bonding for the SA-g-TOCgel (amidation), and β-keto ester linkages for the AKD-g-TOCgel (esterification). As confirmed by CAM, the both chemical treatments enhanced the transition hydrophilic/hydrophobic behavior of the TOCgel fibers. It appeared also that CA values of grafted samples showed a slightly greater hydrophobicity of AKD-g-TOCgel (115° ± 2°) relatively to SA-g-TOCgel (102° ± 2°). However, the absorption rate of water drop seems to be relatively faster for AKD-g-TOCgel than for SA-g-TOCgel. Indeed, the water resistance of amidation product could be due to the high graft efficiency obtained (46.3 %) in comparison with that of the esterification product (30 %). In parallel, this result was confirmed by the dispersion test of modified TOCgels in hexane solvent which indicated clearly the high stable dispersion of SA-g-TOCgel obtained through the amidation process. Moreover, TGA result demonstrated that the thermal stability was found to be slightly higher for SA-g-TOCgel than for AKD-g-TOCgel. Finally, the excellent hydrophobic properties of modified TOCgel material could be suitable to be used as reinforcement for nonpolar polymer matrices in industrial applications.

Similar content being viewed by others

References

Azizi Samir MA, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules 6:612–626

Orts WJ, Shey J, Imam SH, Glenn GM, Guttman ME, Revol JF (2005) Application of cellulose microfibrils in polymer nanocomposites. J Polym Environ 13:301–306

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358

Czaja WK, Young DJ, Kawecki M, Brown RM Jr (2007) The future prospects of microbial cellulose in biomedical applications. Biomacromolecules 8(1):1

Siqueira G, Bras J, Dufresne A (2009) Cellulose whiskers versus microfibrils: influence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. Biomacromolecules 10(2):425–432

Gradwell SE, Renneckar S, Esker AR, Heinze T, Gatenholm P, Vaca-Garcia C, Glasser W (2004) Surface modification of cellulose fibers: towards wood composites by biomimetics. CR Biol 327(9–10):945–953

Baiardo M, Frisoni G, Scandola M, Licciardello A (2002) Surface chemical modification of natural cellulose fibers. J Appl Polym Sci 83(1):38–45

Belgacem M, Gandini A (2005) The surface modification of cellulose fibres for use as reinforcing elements in composite materials. Compos Interfaces 12:41–75

Bledzki AK, Gassan J (1999) Composites reinforced with cellulose based fibers. Prog Polym Sci 24:221–274

Tingaut P, Zimmermann T, Lopez-Suevos F (2010) Synthesis and characterization of bionanocomposites with tunable properties from poly(lactic acid) and acetylated microfibrillated cellulose. Biomacromolecules 11(2):454–464

Lonnberg H, Zhou Q, Brumer H, Teeri TT, Malmstrom E, Hult A (2006) Grafting of cellulose fibers with poly(e-caprolactone) and poly(l-lactic acid) via ring-opening polymerization. Biomacromolecules 7(7):2178–2185

Roy D, Guthrie JT, Perrier S (2005) Graft polymerization: grafting poly(styrene) from cellulose via reversible addition-fragmentation chain transfer (RAFT) polymerization. Macromolecules 38(25):10363–10372

Carlmark A, Malmstrom E (2003) ATRP grafting from cellulose fibers to create block-copolymer grafts. Biomacromolecules 4(6):1740–1745

Coskun M, Temüz MM (2005) Grafting studies onto cellulose by atom-transfer radical polymerization. Polym Int 54(2):342–347

Gaiolas C, Belgacem MN, Silva L, Thielemans W, Costa AP, Nunes M, Silva MJS (2009) Green chemicals and process to graft cellulose fiber. J Colloid Interface Sci 330(2):298–302

Ly B, Bras J, Sadocco P, Belgacem MN, Dufresne A, Thielemans W (2010) Surface functionalization of cellulose by grafting oligoether chains. Mater Chem Phys 120(2–3):438–445

Benkaddour A, Jradi K, Robert S, Daneault C (2013) Grafting of polycaprolactone on oxidized nanocelluloses by click chemistry. Nanomaterials 3:141–157

Lin N, Huang J, Dufresne A (2012) Preparation, properties and applications of polysaccharide nanocrystals in advanced functional nanomaterials. Nanoscale 11(4):3274–3294

Chanzy H (1990) Aspects of cellulose structure. In: Kennedy JF, Philips GO, William PA (eds) Cellulose sources and exploitation. Ellis Horwood Ltd, New York, p 3–12

Marchessault RH, Morehead FF, Walter NM (1959) Liquid crystal systems from fibrillar polysaccharides. Nature 184:632

Kim J, Yun S, Ounaies Z (2006) Discovery of cellulose as a smart material. Macromolecules 39:4202

Paakko M, Ankerfors M, Kosonen H, Nykanen A, Ahola S, Osterberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindstrom T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934

Elazzouzi-Hafraoui S, Nishiyama Y, Putaux JL, Heux L, Dubreuil F, Rochas C (2008) The shape and size distribution of crystalline nanoparticles prepared by acid hydrolysis of native cellulose. Biomacromolecules 9:57

Saito T, Nishiyama Y, Putaux JL, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7:1687

Loranger E, Piché AO, Daneault C (2012) Influence of high shear dispersion on the production of cellulose nanofibers by ultrasound-assisted TEMPO-oxidation of kraft pulp. Nanomaterials 2(3):286–297

Loranger E, Paquin M, Daneault C, Chabot B (2011) Comparative study of sonochemical effects in an ultrasonic bath and in a large-scale flow-through sonoreactor. Chem Eng J 178:359–365

Okita Y, Saito T, Isogai A (2010) Entire surface oxidation of various cellulose microfibrils by TEMPO-mediated oxidation. Biomacromolecules 11:1696

Lasseuguette E (2008) Grafting onto cellulose microfibrils. Cellulose 15:571–580

Araki J, Wada M, Kuga S (2001) Steric stabilization of a cellulose microcrystal suspension by poly(ethylene glycol) grafting. Langmuir 17:21

Johnson RK, Zink-Sharp A, Glasser WG (2011) Preparation and characterization of hydrophobic derivatives of TEMPO-oxidized nanocellulose. Cellulose 18:1599–1609

Oh SY, Yoo DI, Shin Y, Seo G (2005) FTIR analysis of cellulose treated with sodium hydroxide and carbon dioxide. Carbohydr Res 340:417–428

Barazzouk S, Daneault C (2012) Tryptophan-based peptides grafted onto oxidized nanocellulose. Cellulose 19:481–493

Missoum K, Bras J, Belgacem MN (2012) Organization of aliphatic chains grafted on nanofibrillated cellulose and influence on final properties. Cellulose 19:1957–1973

Kamdem DP, Zhang J, Adnot A (2001) Identification of cupric and cuprous copper in copper naphthenate-treated wood by X-ray photoelectron spectroscopy. Holzforschung 55:16–20

Johansson LS, Campbell JM (2004) Reproducible XPS on biopolymers: cellulose studies. Surf Interface Anal 36:1018–1022

Ahmed A, Adnot A, Grandmaison JL, Kaliaguine S, Doucet J (1987) ESCA analysis of cellulosic materials. Cellulose Chem Technol 21(5):483–492

Song X, Chen F, Liu F (2012) Preparation and characterization of alkyl ketene dimer (AKD) modified cellulose composite membrane. Carbohydr Polym 88:417–421

Matuana LM, Balatinecz JJ, Sodhi RNS, Park CB (2001) Surface characterization of esterified cellulosic fibers by XPS and FTIR Spectroscopy. Wood Sci Technol 35:191–201

Habibi Y, Goffin AL, Schiltz N, Duquesne E, Dubois P, Dufresne A (2008) Bionanocomposites based on poly(3-caprolactone)-grafted cellulose nanocrystals by ring-opening polymerization. J Mater Chem 18:5002–5010

Littunen K, Hippi U, Johansson LS, Österberg M, Tammelin T, Liane J, SeppäläJ (2011) Free radical graft copolymerization of nanofibrillated cellulose with acrylic monomers. Carbohydr Polym 84:1039–14047

Rambo CR, Recouvreux DOS, Carminatti CA, Pitlovanciv AK, Antonio RV, Porto LM (2008) Template assisted synthesis of porous nanofibrous cellulose membranes for tissue engineering. Mater Sci Eng C 28:549

Cunha AG, Freire CSR, Silvestre AJD, Neto CP, Gandini A, Orblin E, Fardim P (2007) Highly hydrophobic bio- polymers prepared by the surface pentafluorobenzoylation of cellulose substrates. Biomacromolecules 8:1347–1352

Cassie ABD, Baxter S (1944) Wettability of porous surfaces. Trans Faraday Soc 40:546–551

Acknowledgements

The authors gratefully acknowledge the Natural Science and Engineering Research Council of Canada (NSERC) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Benkaddour, A., Journoux-Lapp, C., Jradi, K. et al. Study of the hydrophobization of TEMPO-oxidized cellulose gel through two routes: amidation and esterification process. J Mater Sci 49, 2832–2843 (2014). https://doi.org/10.1007/s10853-013-7989-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7989-y