Abstract

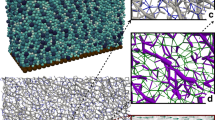

Secondary cone-type crushing machines are an important part of the aggregate production process. These devices process roughly crushed material into aggregate of greater consistency and homogeneity. We apply a continuum model for granular materials (Jop et al., Nature 441:727–730, 2006) to flows of granular material in representative two-dimensional channels, applying a cyclic applied crushing stress in lieu of a moving boundary. Using finite element methods, we solve a sequence of quasi-steady fluid problems within the framework of a pressure-dependent particle size problem in time. Upon approximating output quantity and particle size, we adjust the frequency and strength of the crushing stroke to assess their impacts on the output.

Similar content being viewed by others

References

Jop P, Forterre Y, Pouliquen O (2006) A consitutive law for dense granular flows. Nature 441:727–730

Evertsson CM (1999) Modelling of flow in cone crushers. Miner Eng 12(12):1479–1499

Evertsson CM (2000) Cone crusher performance. PhD Thesis, Department of Machine and Vehicle Design, Chalmers University of Technology

Broadbent SR, Callcott TG (1956) A new analysis of coal breakage processes. J Inst Fuel 29:524–539

Lindqvist M, Evertsson CM (2003) Prediction of worn geometry in cone crushers. Miner Eng 16(12):1355–1361

Lindqvist M, Evertsson CM (2004) Improved flow- and pressure model for cone crushers. Miner Eng 17(11–12):1217–1225

Bengtsson M, Evertsson CM (2006) An empirical model for predicting flakiness in cone crushers. J Miner Process 79:49–60

Lindqvist M, Evertsson CM (2006) Development of wear model for cone crushers. Wear 261:435–442

Lindqvist M, Evertsson M, Chenje T, Radziszewski P (2006) Influence of particle size on wear rate in compressive crushing. Miner Eng 19:1328–1335

Hulthén E, Evertsson CM (2009) Algorithm for dynamics cone crusher control. Miner Eng 22:296–303

Lee E, Evertsson CM (2011) A comparative study between cone crushers and theoretically optimal crushing sequences. Miner Eng 24(3–4):188–194

Huang D, Fan X, Wu D, Yao F (2007) Multi-objective planning of cone crusher chamber, output and size reduction. Miner Eng 20:163–172

Huang D, Fan X, Wu D, Yao F (2008) Research on cone crusher chamber geometry. China Mech Eng 19(17):2041–2045,2049

Dong G, Fan X, Huang D (2009) Analysis and optimization of cone crusher performance. Miner Eng 22(12):1091–1093

Dong G, Huang D, Fan X (2009) Cone crusher chamber optimization using multiple constraints. Int J Miner Process 93:204–208

Goldhirsch I (2003) Rapid granular flows. Annu Rev Fluid Mech 35:267–293

Nedderman RM (1992) Statics and kinematics of granular materials. Cambridge University Press, Cambridge

Janssen HA (1895) Versuche über getreidedruck in silozellen. Zeitschr. d. Vereines deutscher Ingenieure 39:1045

Sperl M (2006) Experiments on corn pressure in silo cells—translation and comment of Janssen’s paper from 1895. Granul Matter 8:59–65

Boutreux T, Raphaël E, de Gennes PG (1997) Propagation of a pressure step in a granular material: the role of wall friction. Phys Rev E 55(5):5759–5773

de Gennes PG (1999) Granular matter: a tentative view. Rev Mod Phys 71(2):S374–S382

Ertaş D, Halsey TC (2002) Granular gravitational collapse and chute flow. Europhys Lett 60(6):931–937

Dean EJ, Glowinski R, Guidoboni G (2007) On the numerical simulation of Bingham visco-plastic flow: old and new results. J Non-Newton Fluid Mech 142:36–62

Papanastasiou TC (1987) Flows of materials with yield. J Rheol 31(5):385–404

Papanastasiou TC, Boudouvis AG (1997) Flows of viscoplastic materials: models and computations. Comput Struct 64(1–4):677–694

Kinderlehrer D (1978) Variational inequalities and free boundary problems. Bull Am Math Soc 84(1):7–26

Huilgol RR (2002) Variational inequalities in the flows of yield stress fluids including inertia: theory and applications. Phys Fluids 14(3):1269–1283

Domnik B, Pudasaini SP (2012) Full two-dimensional rapid chute flows of simple viscoplastic granular materials with a pressure-dependent dynamic slip-velocity and their numerical solutions. J Non-Newton Fluid Mech 173–174:72–86

Bearman RA, Briggs CA (1998) The active use of crushers to control product requirements. Miner Eng 11(9):849–859

Ide JM (1936) Comparison of statically and dynamically determined Young’s modulus of rocks. Proc Natl Acad Sci 22(2):81–92

Roquet N, Saramito P (2008) An adaptive finite element method for viscoplastic flows in a square pipe with stick-slip at the wall. J Non-Newton Fluid Mech 155:101–115

Rao IJ, Rajagopal KR (1999) The effect of the slip boundary condition on the flow of fluids in a channel. Acta Mech 135:113–126

Gatica GN, Maischak M, Stephan EP (2011) Numerical of a transmission problem with Signorini contact using mixed-FEM and BEM. ESAIM 45:779–802

de Souza Mendes PR, Naccache MF, Varges PR (2007) Flow of viscoplastic liquids through axisymmetric expansions–contractions. J Non-Newton Fluid Mech 142(1–3):207–217

Daouadji A, Hicher P-Y (2009) An enhanced constitutive model for crushable granular materials. Int J Numer Anal Methods Geomech 34:555–580

Bika DG, Gentzler M, Michaels JN (2001) Mechanical properties of agglomerates. Powder Technol 117:98–112

Shipway PH, Hutchings IM (1993) Attrition of brittle spheres by fracture under compressionand impact loading. Powder Technol 26:23–30

Couroyer C, Ning Z, Ghadiri M, Brunard N, Kolenda F, Bortzmeyer D, Laval P (1999) Breakage of macroporous alumina beads under compressive loading: simulation and experimental validation. Powder Technol 105:57–65

Nitsche J (1971) Über ein Variationsprinzip zur Lösung von Dirichlet Problemen bei Verwendung von Teilräumen, die keinen Randbedingungen unterworfen sind. Abhandlungen aus dem Mathematischen Seminar der Universitt Hamburg 36:9–15

Acknowledgments

We would like to thank the EPSRC and Terex Pegson, especially Ian Boast and Tim Cummings of Terex Pegson, for their promotion and sponsorship of this CASE project. We also thank the the University of Nottingham for their wonderful staff and facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bain, O., Billingham, J., Houston, P. et al. Flows of granular material in two-dimensional channels. J Eng Math 98, 49–70 (2016). https://doi.org/10.1007/s10665-015-9810-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10665-015-9810-1