Abstract

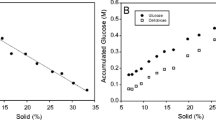

The enzymatic hydrolysis of lignocelluloses is a key step in the production of ethanol. Economic considerations for large-scale implementation of the process require operation at high solid concentrations. However, the decrease in cellulose conversion offsets the advantages of working at high solid concentrations. The conversion showed a linear decrease in the reaction of pretreated corn stover (PCS) from 2 to 20 % (w/w) and filter paper from 1 to 10 % (w/w) initial total solid content. Hydrolysis experiments with PCS at various mixing speeds showed that the mass transfer limitation could not restrict the cellulose conversion except the solid concentrations over 5 % DM(w/w). The lignin, if added separately, does not correspond directly to the decrease. At increased concentrations, furfural and 5-hydroxymethylfurfural played a part in the effect, and 5-hydroxymethylfurfural only affected exoglucanase. Product inhibition caused by glucose accumulation at increased solid concentrations was found to be a significant and perhaps principal factor. The decrease in yield was caused by the synergetic inhibition, which was more serious with increased solid concentrations.

Similar content being viewed by others

References

Andric P, Meyer AS, Jensen PA, Dam-Johansen K (2010) Reactor design for minimizing product inhibition during enzymatic lignocellulose hydrolysis: II. Quantification of inhibition and suitability of membrane reactors. Biotechnol Adv 28(3):407–425

Berlin A, Balakshin M, Gilkes N, Kadla J, Maximenko V, Kubo S, Saddler J (2006) Inhibition of cellulase, xylanase and β-glucosidase activities by softwood lignin preparations. J Biotechnol 125(2):198–209

Cantarella M, Cantarella L, Gallifuoco A, Spera A, Alfani F (2004) Effect of inhibitors released during steam-explosion treatment of poplar wood on subsequent enzymatic hydrolysis and SSF. Biotechnol Prog 20(1):200–206

Cao Y, Tan H (2004) The effect of shear field on the hydrolysis of cellulose. J Macromol Sci Part B 43(6):1115–1121

Dashtban M, Maki M, Leung KT, Mao C, Qin W (2010) Cellulase activities in biomass conversion: measurement methods and comparison. Crit Rev Biotechnol 30(4):302–309

Du J, Zhang F, Li, Y, Zhang H, Liang J, Zheng H, Huang H (2014) Enzymatic liquefaction and saccharification of pretreated corn stover at high-solids concentrations in a horizontal rotating bioreactor. Bioprocess Biosyst Eng 37(2):173–181

Eriksson T, Börjesson J, Tjerneld F (2002) Mechanism of surfactant effect in enzymatic hydrolysis of lignocellulose. Enzyme Microbial Technol 31(3):353–364

Fan Z, South C, Lyford K, Munsie J, van Walsum P, Lynd LR (2003) Conversion of paper sludge to ethanol in a semicontinuous solids-fed reactor. Bioprocess Biosyst Eng 26(2):93–101

Himmel ME, Ding SY, Johnson DK, Adney WS, Nimlos MR, Brady JW, Foust TD (2007) Biomass recalcitrance: engineering plants and enzymes for biofuels production. Science 315(5813):804–807

Hodge DB, Karim MN, Schell DJ, McMillan JD (2008a) Model-based fed-batch for high-solids enzymatic cellulose hydrolysis. Appl Biochem Biotechnol 152(1):88–107

Hodge DB, Karim MN, Schell DJ, McMillan JD (2008b) Soluble and insoluble solids contributions to high-solids enzymatic hydrolysis of lignocellulose. Bioresour Technol 99(18):8940–8948

Jorgensen H, Vibe-Pedersen J, Larsen J, Felby C (2007) Liquefaction of lignocellulose at high-solids concentrations. Biotechnol Bioeng 96(5):862–870

Jørgensen H, Vibe-Pedersen J, Larsen J, Felby C (2007) Liquefaction of lignocellulose at high-solids concentrations. Biotechnol Bioeng 96(5):862–870

Klinke HB, Thomsen A, Ahring BK (2004) Inhibition of ethanol-producing yeast and bacteria by degradation products produced during pre-treatment of biomass. Appl Microbiol Biotechnol 66(1):10–26

Kristensen JB, Thygesen LG, Felby C, Jørgensen H, Elder T (2008) Cell-wall structural changes in wheat straw pretreated for bioethanol production. Biotechnol Biofuels 1(5):1–9

Kristensen JB, Felby C, Jørgensen H (2009) Yield-determining factors in high-solids enzymatic hydrolysis of lignocellulose. Biotechnol Biofuels 2(1):11

Larsen J, Østergaard Petersen M, Thirup L, Wen Li H, Krogh Iversen F (2008) The IBUS process—lignocellulosic bioethanol close to a commercial reality. Chem Eng Technol 31(5):765–772

Larsen J, Haven MØ, Thirup L (2012) Inbicon makes lignocellulosic ethanol a commercial reality. Biomass Bioenergy 46:36–45

Liu H, Zhu JY, Fu SY (2010) Effects of lignin-metal complexation on enzymatic hydrolysis of cellulose. J Agric Food Chem 58(12):7233–7238

Mais U, Esteghlalian AR, Saddler JN (2002a) Influence of mixing regime on enzymatic saccharification of steam-exploded softwood chips. Appl Biochem Biotechnol 98(1):463–472

Mais U, Esteghlalian AR, Saddler JN, Mansfield SD (2002b) Enhancing the enzymatic hydrolysis of cellulosic materials using simultaneous ball milling. Appl Biochem Biotechnol 98(1):815–832

Mohagheghi A, Tucker M, Grohmann K, Wyman C (1992) High solids simultaneous saccharification and fermentation of pretreated wheat straw to ethanol. Appl Biochem Biotechnol 33(2):67–81

Nakagame S, Chandra RP, Kadla JF, Saddler JN (2011) The isolation, characterization and effect of lignin isolated from steam pretreated Douglas-fir on the enzymatic hydrolysis of cellulose. Bioresour Technol 102(6):4507–4517

Pan X (2008) Role of functional groups in lignin inhibition of enzymatic hydrolysis of cellulose to glucose. J Biobased Mater Bioenergy 2(1):25–32

Panagiotou G, Olsson L (2006) Effect of compounds released during pretreatment of wheat straw on microbial growth and enzymatic hydrolysis rates. Biotechnol Bioeng 96(2):250–258

Schell D, Farmer J, Newman M, McMillan J (2003) Dilute-sulfuric acid pretreatment of corn stover in pilot-scale reactor. Appl Biochem Biotechnol 105(1–3):69–85

Schwald W, Breuil C, Brownell H, Chan M, Saddler J (1989) Assessment of pretreatment conditions to obtain fast complete hydrolysis on high substrate concentrations. Appl Biochem Biotechnol 20(1):29–44

Tengborg C, Galbe M, Zacchi G (2001) Influence of enzyme loading and physical parameters on the enzymatic hydrolysis of steam-pretreated softwood. Biotechnol Prog 17(1):110–117

Varga E, Klinke HB, Réczey K, Thomsen AB (2004) High solid simultaneous saccharification and fermentation of wet oxidized corn stover to ethanol. Biotechnol Bioeng 88(5):567–574

Várnai A, Viikari L, Marjamaa K, Siika-Aho M (2011) Adsorption of monocomponent enzymes in enzyme mixture analyzed quantitatively during hydrolysis of lignocellulose substrates. Bioresour Technol 102(2):1220–1227

Weiss N, Börjesson J, Pedersen LS, Meyer AS (2013) Enzymatic lignocellulose hydrolysis: improved cellulase productivity by insoluble solids recycling. Biotechnol Biofuels 6(1):5

Wingren A, Galbe M, Zacchi G (2003) Techno-economic evaluation of producing ethanol from softwood: comparison of SSF and SHF and identification of bottlenecks. Biotechnol Prog 19(4):1109–1117

Wood TM, Bhat KM (1988) Methods for measuring cellulase activities. Methods Enzymol 160:87–112

Wu B, Zhao Y, Gao PJ (2006) A new approach to measurement of saccharifying capacities of crude cellulase. Bioresources 1(2):189–200

Yang J, Zhang X, Yong Q, Yu S (2010) Three-stage hydrolysis to enhance enzymatic saccharification of steam-exploded corn stover. Bioresour Technol 101(13):4930–4935

Zaldivar J, Nielsen J, Olsson L (2001) Fuel ethanol production from lignocellulose: a challenge for metabolic engineering and process integration. Appl Microbiol Biotechnol 56(1–2):17–34

Zheng R, Zhang H, Zhao J, Lei M, Huang H (2011) Direct and simultaneous determination of representative byproducts in a lignocellulosic hydrolysate of corn stover via gas chromatography-mass spectrometry with a Deans switch. J Chromatogr A 1218(31):5319–5327

Acknowledgments

This work was funded by the Independent Innovation Project of Jiangsu Province [no. CX (11)2051].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Du, J., Li, Y., Zhang, H. et al. Factors to decrease the cellulose conversion of enzymatic hydrolysis of lignocellulose at high solid concentrations. Cellulose 21, 2409–2417 (2014). https://doi.org/10.1007/s10570-014-0301-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0301-8