Abstract

This paper reports a new low-cost passive microfluidic mixer design, based on a replication of identical mixing units composed of microchannels with variable curvature (clothoid) geometry. The micromixer presents a compact and modular architecture that can be easily fabricated using a simple and reliable fabrication process. The particular clothoid-based geometry enhances the mixing by inducing transversal secondary flows and recirculation effects. The role of the relevant fluid mechanics mechanisms promoting the mixing in this geometry were analysed using computational fluid dynamics (CFD) for Reynolds numbers ranging from 1 to 110. A measure of mixing potency was quantitatively evaluated by calculating mixing efficiency, while a measure of particle dispersion was assessed through the lacunarity index. The results show that the secondary flow arrangement and recirculation effects are able to provide a mixing efficiency equal to 80 % at Reynolds number above 70. In addition, the analysis of particles distribution promotes the lacunarity as powerful tool to quantify the dispersion of fluid particles and, in turn, the overall mixing. On fabricated micromixer prototypes the microscopic-Laser-Induced-Fluorescence (μLIF) technique was applied to characterize mixing. The experimental results confirmed the mixing potency of the microdevice.

Similar content being viewed by others

References

C. Allain, M. Cloitre, Phys Rev A 44, 3552 (1991)

M.A. Ansari, K.-Y. Kim, K. Anwar, S.M. Kim, J Micromech Microeng 20, 055007 (2010)

F.G. Bessoth, A.J. de Mello, A. Manz, Anal Commun 36, 213 (1999)

D. Bothe, C. Stemich, H.-J. Warnecke, Chem Eng Sci 61, 2950 (2006)

C.K. Chung, T.R. Shih, J Micromech Microeng 17, 2495 (2007)

C.K. Chung, T.R. Shih, Microfluid Nanofluid 4, 419 (2008)

C.K. Chung, T.R. Shih, T.C. Chen, B.H. Wu, Biomed Microdevices 10, 739 (2008)

C.K. Chung, T.R. Shih, B.H. Wu, C.K. Chang, Microsyst Technol 16, 1595 (2010)

W.R. Dean, Philos Mag 5, 673 (1928)

Y.F. Fan, I. Hassan, Exp Fluids 49, 733 (2010)

A. Gigras, S. Pushpavanam, Microfluid Nanofluid 5, 89 (2008)

S. Hardt, K.S. Drese, V. Hessel, F. Schönfeld, Microfluid Nanofluid 1, 108 (2005)

V. Hessel, H. Löwe, F. Schönfeld, Chem Eng Sci 60, 2479 (2005)

M. Hoffmann, M. Schlüter, N. Räbiger, Chem Eng Sci 61, 2968 (2006)

P.B.J. Howell, D.R. Mott, J.P. Golden, F.S. Ligler, Lab Chip 4, 663 (2004)

F. Jiang, K. Drese, S. Hardt, M. Küpper, F. Schönfeld, AIChE J 50, 2297 (2004)

D.S. Kim, S.H. Lee, T.H. Kwon, C.H. Ahn, Lab chip 5, 739 (2005)

M.G. Lee, S. Choi, J.-K. Park, Biomed Microdevices 12, 1019 (2010)

C.H. Lin, G.B. Lee, Y.H. Lin, G.L. Chang, J Micromech Microeng 11, 726 (2001)

C.H. Lin, C.H. Tsai, L.M. Fu, Biomed Microdevices 9, 43 (2007)

R.H. Liu, M.A. Stremler, K.V. Sharp, M.G. Olson, J.G. Santiago, R.J. Adrian, H. Aref, D.J. Beebe, J Microelectromech S 9, 190 (2000)

R.H. Liu, J. Yang, M.Z. Pindera, M. Athavale, P. Grodzinski, Lab Chip 2, 151 (2002)

P. Löb, K.S. Drese, V. Hessel, S. Hardt, C. Hofmann, H. Löwe, R. Schenk, F. Schönfeld, B. Werner, Chem Eng Technol 27, 340 (2004)

B.B. Mandelbrot, The Fractal Geometry of Nature (W. H. Freeman and Company, San Francisco, 1983)

S.L. Marasso, E. Giuri, G. Canavese, R. Castagna, M. Quaglio, I. Ferrante, D. Perrone, M. Cocuzza, Biomed Microdevices 13, 19 (2011)

R. Matsumoto, H. Zadeh, P. Ehrhard, Exp Fluids 39, 722 (2005)

X. Niu, Y.-K. Lee, J Micromech Microeng 13, 454 (2003)

N.-T. Nguyen, Z. Wu, J Micromech Microeng 15, R1 (2005)

N.-T. Nguyen, Micromixers : fundamentals, design and fabrication (William Andrew Micro & Nano Technologies Series, 2008)

F. Pennella, F. Mastrangelo, D. Gallo, D. Massai, M.A.Deriu, G. FalvoD’UrsoLabate, C. Bignardi, F. Montevecchi, U. Morbiducci, in Single and two-Phase Flows on Chemical and Biomedical Engineering,ed. By Dias R, (Bentham, London, 2011) in press.

F. Piraino, G. Camci-Unal, M.J. Hancock, M. Rasponi, A. Khademhosseini, Lab Chip 12, 659 (2012)

R. Plotnick, R. Gardner, R. O’ Neill, Landscape Ecol 8, 201 (1993)

F. Schönfeld, S. Hardt, AIChE J 50, 771 (2004)

Š. Selimović, F. Piraino, H. Bae, M. Rasponi, A. Redaelli, A. Khademhosseini, Lab Chip 11, 2325–2011 (2011)

D. Sinton, Microfluid Nanofluid 1, 2 (2004)

A.D. Stroock, S.K.W. Dertinger, A. Ajdari, I. Mezic, H.A. Stone, G.M. Whitesides, Science 295, 647 (2002)

A.P. Sudarsan, V.M. Ugaz, Lab Chip 6, 74 (2006)

G.M. Whitesides, E. Ostuni, S. Takayama, X. Jiang, D.E. Ingber, Annu Rev Biomed Eng 3, 335 (2001)

M.E. Wilson, N. Kota, Y.T. Kim, Y. Wang, D.B. Stolz, P.R. LeDuc, O.B. Ozdoganlar, Lab Chip 11, 1550 (2011)

Y.N. Xia, G.M. Whitesides, Annu Rev Mater Sci 28, 153 (1998)

Y. Yamaguchi, F. Takagi, K. Yamashita, H. Nakamura, H. Maeda, K. Sotowa, K. Kusakabe, Y. Yamasaki, S. Morooka, AIChE J 50, 1530 (2003)

Y. Yamaguchi, F. Takagi, T. Watari, K. Yamashita, H. Nakamura, H. Shimizu, H. Maeda, Chem Eng J 101, 367 (2004)

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

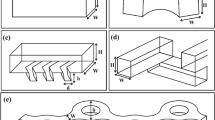

An advantage in using clothoid microchannels as basic segments in micromixers is related to the possibility for secondary flows generation (and mixing promotion as a consequence) with footprint in the downstream direction shorter than fixed-curvature (ring) microchannels. A curved microchannel is characterized by two parameters, i.e., curvature and length. To compare the performance, in terms of mixing efficiency, of a fixed-curvature microchannel (Fig. 13, geometry A) as studied by Schönfeld and Hardt (2004) and a clothoid microchannel with the same hydraulic diameter, the influence of geometric features was analyzed disjointedly. In detail, clothoid microchannels with (1) the same length (Fig. 13, geometry B) as and (2) initial curvature as fixed-curvature microchannel (Fig. 13, geometry C) were investigated. Table 2 shows the values of the parameters taken in consideration in this example. Figure 13 clearly shows that an advantage of clothoid microchannels is that they have a footprint lower than fixed-curvature microchannels, in the downstream direction (length footprint (Lfp) is almost 20 % (clothoid B) and 40 % (clothoid C) lower than ring microchannel (A); the length of clothoid channel C is almost the 60 % of ring channel A length). A Lfp of clothoid microchannels lower than fixed-curvature geometries could represent a real advantage in fabrication process when micromixers based on convective mixing have to be incorporated into a microchip. This is an important aspect because, in general, mixing efficiency is evaluated in terms of minimum mixing distance.

To demonstrate the potency of clothoid microchannels as basic units for mixing generation, we (1) performed CFD simulations and (2) used computational results to estimate the effect of secondary flows on convective mixing in the three microchannel geometries summarized in Table 2. CFD simulations were performed by solving the same equations as described in the Materials and Methods section, mimicking the presence of two different fluids.

As an example of the results obtained from simulations, Fig. 14 shows the concentration distribution of the two fluids and the interface deformation at the outlet section, at the same flow regime (Re = 75). It can be noticed that the shape of the interface is very similar at the outlet section of fixed-curvature (A) and clothoid microchannels (B, C).

Interface deformation at the outlet section of (a) the fixed-curvature segment, (b) the clothoid segment with same length as geometry A and (c) the clothoid segment with initial curvature as curvature of geometry A. (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article)

In clothoid microchannels, the fluid experiences an increase in the channel curvature as it flows downstream, accompanied by an increased amount of secondary flows. To quantify the convective effect of secondary flows on mixing, we defined a dimensionless quantity, the Interfacial gain (IG), a measure of the increment of interface area for unitary length of the channel. Being L(s) the length of the curve given by the intersection between the miscible streams and the channel cross section at the generic channel length s (i.e., the interface length), IG can be expressed as

where D is the characteristic length of the microchannel cross section, A is the interface area, rc is the radial coordinate of the centroid of the interface line L(s). The interface area depends upon the radius of curvature of the interface line centroid via the Pappus’s centroid theorem. The length of the interface at the inlet section L(0) is equal to D. Roughly speaking, IG estimates mixing potency from the increment for unit length of interface area. Table 3 summarizes IG and pressure drop values characterizing the three microchannel geometries in Fig. 13, at the same flow regime (Re = 75).

Notably, the clothoid microchannels exhibit performances that are comparable to the fixed-curvature microchannel both in terms of mixing potency and in terms of pressure drop, but with a lower footprint.

Another reason leading us to use clothoid segments into the micromixer design proposed here is that we observed that in clothoid-shaped meander micromixers the mixing reversal effect observed in devices using fixed-curvature segments (Yamaguchi et al. 2003;Yamaguchi et al. 2004) is attenuated and, as a consequence, the mixing efficiency increased. In detail, we started from findings by Yamaguchi and coworkers (Yamaguchi et al. 2003;Yamaguchi et al. 2004) that at low and intermediate Reynolds flow regimes the interface between two fluids streams in double-curved microchannels with fixed-curvature segments undergo a reversal of the convective phenomenon and, as a consequence, of a convective mixing reversal effect (Fig. 15). In detail, it was observed both experimentally and in silico that the initial interface between two fluids at the inlet section of a meander microchannel made of two fixed-curvature segments was stretched and folded at the outlet of the first curved segment while the effect of the second curved segment was of stretching and folding the interface nullifying the convective effect of the first segment, because inertial forces were exerted in opposite directions; (2) on the contrary, at relatively high Reynolds number, the interface was wave-shaped and kinematic reversibility was marginal in the mixing of fluids.

A meander micromixer unit, made of two fixed-curvature segments operating at Re = 10. Two coloured stream are inserted at the inlet section (left side) and in consequence of secondary flows undergo an increment of contact area which reduces during the reversal of curvature showing kinematic reversibility

Here, the kinematic reversibility in a meander micromixer unit made of two clothoid segments with geometric features as model B in Table 2 was compared with the reversibility occurring in the meander micromixer proposed by the group of Yamaguchi (Yamaguchi et al. 2003;Yamaguchi et al. 2004) and made of segments with geometric features as model A in Table 2. To do it, we used the same approach as for the study on single clothoid and fixed-curvature microchannels. Figure 16 shows the distribution of the fluid streams at the outlet section of the two meander microchannels: at relatively low Reynolds flow regimes (Re < 10) the kinematic reversibility is almost complete, independent of the geometric features of the segments. Anyway, by increasing the flow rate (Re > 25), kinematic reversibility is more attenuated in the clothoid-shaped meander microchannel than in fixed-curvature-shaped. It was found that (1) at intermediate Reynolds flow regimes (Re = 10) the increment of interface area for unitary length (IG) increases to almost 1 during the first segment while in the segment with curvature reversal the IG decreases to almost zero, independent of the geometry of the segment; (2) at relatively high Reynolds flow regimes (Re = 75), at the outlet section of the clothoid-shaped meander microchannel the IG is about 20 % higher than fixed-curvature-shaped meander microchannel (2.18 against 1.82).

Spatial distribution of two immiscible species at the outlet section of the two meander microchannels: for fast flows (Re > 25) the different curvature modulation induces changes in the final distribution of fluids cancelling out the kinematic reversibility. (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article)

A further analysis was carried out in order to get insight into the physical reason at the basis of the observed reduced reversibility in clothoid-shaped meander microchannels. To do it, we calculated the mean value of the streamwise vorticity (STWV) at several cross sections along the curvilinear coordinate s of both the clothoid and fixed-curvature segments B and A (Fig. 13), respectively. As mentioned above, here we took advantage of the existence of a symmetry plane so that STWV was calculated on half of each cross section of microchannels as:

where S is the area of half of the microchannel cross section.

Our findings show that the STWV increases almost linearly with the curvilinear coordinate s in the clothoid segment, while in the fixed-curvature segment the STWV reaches a plateau at about two diameters downstream of the inlet section and remains at almost the same value up to the outlet section, where the STWV in the clothoid is considerably higher than the fixed-curvature segment (Fig. 17).

It is this increased generation of local streamwise vorticity into the clothoid microchannel the responsible for the reduced kinematic reversibility observed in the clothoid-shaped meander micromixer in Fig. 15.

Rights and permissions

About this article

Cite this article

Pennella, F., Rossi, M., Ripandelli, S. et al. Numerical and experimental characterization of a novel modular passive micromixer. Biomed Microdevices 14, 849–862 (2012). https://doi.org/10.1007/s10544-012-9665-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10544-012-9665-4