Abstract

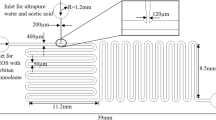

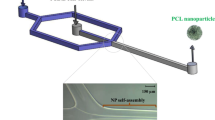

Recent studies show that microfluidic devices are gaining importance as micromixer in chemical and bio-chemical analysis systems. However, little attention has been paid to investigate chemical reactions such as polymerization reaction process in microreactors. In the present study, numerical modeling of the free-radical polymerization of styrene was carried out in novel coiled flow inverter (CFI) microreactor. The concept of CFI is based on the technique developed by Saxena and Nigam (AlChE J 30:363–368, 1984). This device is made up of helical coiled tube which is bent periodically to 90° at equidistant length. The CFD modeling for polymerization reaction taking place in coiled tube reactor was also performed in order to understand the influence of secondary flows on reactor performance for fluid flowing with very low flow rate. Its performance was compared with CFD results obtained in a straight tube reactor having identical length and operating under the same process conditions. The results showed that monomer conversion in the coiled tube reactor was higher than that of the straight tube reactor. Further work was carried out in the novel CFI reactor to study the effect of diffusion coefficient and number of bends on different parameters such as monomer conversion, number-average degree of polymerization (DP n ), and polydispersity indexes (PDI). It was found that the performance of CFI as reactor increased when the diffusion coefficients of reactants was decreased. Thus, CFI was found to be an efficient microfluidic device for controlling the free-radical polymerization.

Similar content being viewed by others

Abbreviations

- C p :

-

Fluid heat capacity (J/kg/K)

- d t :

-

Tube diameter (m)

- D :

-

Diffusion coefficient of species i (m2/s)

- D c :

-

Coil diameter (m)

- DP n :

-

Number-average degree of polymerization

- I :

-

Initiator

- k :

-

Fluid thermal conductivity (W/m/K)

- L :

-

Kinetic chain length or reactor length (m)

- M :

-

Monomer

- n :

-

Flow behavior index

- N Regn :

-

Generalized Reynolds number [=(4n/3n + l)n(l.0/8n−l) (d t u 2−nρ/k)]

- N Sc :

-

Schmidt number [=ρμa/D rn]

- P :

-

Pressure (Pa)

- P t :

-

Pitch

- Q :

-

Heat source (W/m3)

- R i :

-

Rate of production of species i (mol/l/s)

- R :

-

Tubular reactor radius (m)

- t :

-

Time (s)

- T :

-

Temperature (K)

- u :

-

Velocity vector (m/s)

- X M :

-

Monomer conversion

- μ:

-

Viscosity of fluid (Pa s)

- ρ:

-

Density of fluid (kg/m3)

References

Adler M (1934) Flow in curved tubes. Z Angew Math Mech 14:257–275

Agrawal S, Nigam KDP (2001) Modeling of a coiled tubular chemical reactor. Chem Eng J 84:437–444

Beebe DJ, Mensing GA, Walker GM (2002) Physics and applications of microfluidics in biology. Annu Rev Biomed Eng 4:261–286

Cabral PA, Melo PA, Biscaia EC, Lima EL, Pinto JC (2003) Free-radical solution polymerization of styrene in a tubular reactor-effects of recycling. Poly Eng Sci 43:6–9

Castelain C, Mokrani A, Legentilhomme P, Peerhossaini H (1997) Residence time distribution in twisted pipe flows: helically coiled system and chaotic system. Exp Fluids 22:359–368

CFD-ACE+ user manual, ESI CFD Inc., 2008

Chovan T, Guttman A (2002) Microfabricated devices in biotechnology and biochemical processing. Trends Biotechnol 20:116–122

Dean WR (1927) Notes on the motion of fluid in a curved pipe. Philos Mag 4:208–233

Dean WR (1928) The stream line motion of fluid in a curved pipe. Philos Mag 5:673–695

Dowding PJ, Goodwin JW, Vincent B (2000) Production of porous suspension polymers using a continuous tubular reactor. Colloid Poly Sci 278:346–351

Dravid AN, Smith KA, Merrill EW, Brain PLT (1971) Effect of secondary fluid motion on laminar flow heat transfer in helically coiled pipes. AlChE J l17:1114–1122

Huang Y, Mather EL, Bell JL, Madou M (2002) MEMS-based sample preparation for molecular diagnostics. Anal Bioanal Chem 372:49–65

Jakeway SC, de Mello AJ, Russell EL (2000) Miniaturized total analysis systems for biological analysis. Fresenius J Anal Chem 366:525–539

Jiang F, Drese KS, Hardt S, Kupper M, Schönfeld F (2004) Helical flows and chaotic mixing in curved micro channels. AIChE J 50:2297–2305

Kalb CE, Seader JD (1972) Heat and mass transfer phenomena for viscous flow in curved circular pipe. Int J Heat Mass Transf 15:801–817

Kubair V, Kuloor NR (1966) Heat transfer to Newtonian fluid in coiled pipes in laminar flow. Int J Heat Mass Transf 9:63–75

Kumar V, Mridha M, Gupta AK, Nigam KDP (2007a) Coiled flow inverter as a heat exchanger. Chem Eng Sci 62:2386–2396

Kumar V, Vashisth S, Hoarau Y, Nigam KDP (2007b) Slug flow in curved microreactors: hydrodynamic study. Chem Eng Sci 62:7494–7504

Mandal MM, Nigam KDP (2009) Experimental study on pressure drop and heat transfer of turbulent flow in tube in tube helical heat exchanger. Ind Eng Chem Res 48:9318–9324

Mashelkar RA, Venkatasubramanian CV (1985) Influence of secondary flow in diffusion with reaction. AIChE J 31:440–449

Mishra P, Gupta SN (1979) Momentum transfer in curved pipes 1. Newtonian fluids; 2. non-Newtonian fluids. Indian Eng Chem Process Des Dev 18:130–142

Mridha M, Nigam KDP (2008) Coiled flow inverter as an inline mixer. Chem Eng Sci 63:1724–1732

Nagy A, Faust R, Kennedy JR (1986) Living carbocationic polymerization. Polym Bull 15:411–416

Nigam KDP, Saxena AK (1986) Residence time distribution in straight and curved tube. In: Cheremisinoff NP (ed) Encyclopedia of fluid mechanics, vol 1. Gulf Publishing, Houston, pp 675–762

Ranade VR, Ulbrecht JJ (1981) The residence time distribution for laminar flow of non-Newtonian liquids through helical tubes. Chem Eng Commun 8:165–176

Rosenfeld C, Serra C, Brochon C, Hadziioannou G (2007) High-temperature nitroxide-mediated radical polymerization in a continuous microtube reactor: towards a better control of the polymerization reaction. Chem Eng Sci 62:5245–5250

Sarry N (2004) Polymérisation dans des systèmes microfluidiques. Master Thesis, Laboratoire d’Ingénierie des Polymères pour les Hautes Technologies (LIPHT), Université Louis Pasteur, France

Saxena AK, Nigam KDP (1981) Axial dispersion in laminar flow of polymer solutions through coiled tubes. J Appl Polym Sci 26:3475–3486

Saxena AK, Nigam KDP (1984) Coiled configuration for flow inversion and its effect on residence time distribution. AlChE J 30:363–368

Serra C, Schlatter G, Sary N, Schonfeld F, Hadziioannou G (2007) Free radical polymerization in multilaminated microreactors: 2D and 3D multiphysics CFD modeling. Microfluid Nanofluid 3:3451–3461

Shuchkin VK (1969) Correlation for experimental data on heat transfer in curved pipes. Therm Eng 16:72–76

Tüdos AJ, Besselink GAJ, Schasfoort RBM (2001) Trends in miniaturized total analysis systems for point-of-care testing in clinical chemistry. Lab Chip 1:83–95

Vashisth S, Kumar V, Nigam KDP (2008) A review on the potential application of curved geometries in process industries. Ind Eng Chem Res 47:3291–3337

Verpoorte E (2002) Microfluidic chips for clinical and forensic analysis. Electrophoresis 23:677–712

Vo-Dinh T, Cullum B (2000) Biosensors and biochips: advances in biological and medical diagnostics. Fresenius J Anal Chem 366:540–551

Acknowledgment

The authors gratefully acknowledge the Science & Technology Service, French Embassy in India for financial support of the project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mandal, M.M., Serra, C., Hoarau, Y. et al. Numerical modeling of polystyrene synthesis in coiled flow inverter. Microfluid Nanofluid 10, 415–423 (2011). https://doi.org/10.1007/s10404-010-0679-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-010-0679-z