Abstract

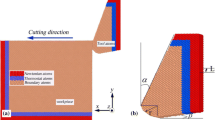

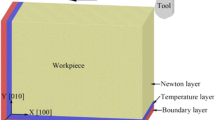

A three-dimensional molecular dynamics simulation study is conducted to investigate repeated single-point turnings of a monocrystalline silicon specimen with diamond tools at nanometric scale. Morse potential energy function and Tersoff potential energy function are applied to model the silicon/diamond and silicon/silicon interactions, respectively. As repeated nano-cutting process on surfaces often involve the interactions between the consequent machining processes, repeated single-point diamond turnings are employed to investigate the phase transformation in the successive nano-cutting processes. The simulation results show that a layer of the damaged residual amorphous silicon remained beneath the surface after the first-time nano-cutting process. The amorphous phase silicon deforms and removes differently in the second nano-cutting process. By considering the coordination number (CN) of silicon atoms in the specimen, it is observed that there is an increase of atoms with six nearest neighbors during the second nano-cutting process. It suggests that the recovery of the crystalline phase from the amorphous phase occurred. Moreover, the instantaneous temperature distributions in the specimen are analyzed. Although the tangential force (F X ) and the thrust force (F Y ) become much smaller in the second cutting process, the material resistance rate is larger than the first cutting process. The larger resistance also induces the increase of local temperature between the cutting tool and the amorphous layer in the second cutting process.

Similar content being viewed by others

References

Y.H. Lin, S.R. Jian, Y.S. Lai, P.F. Yang, Molecular dynamics simulation of nanoindentation-induced mechanical deformation and phase transformation in monocrystalline silicon. Nanoscale Res. Lett. 3, 71–75 (2008)

Y.H. Lin, T.C. Chen, A molecular dynamics study of phase transformations in mono-crystalline Si under nanoindentation. Appl. Phys. A 92, 571–578 (2008)

Q.X. Pei, C. Lu, H.P. Lee, Y.W. Zhang, Study of materials deformation in nanometric cutting by large-scale molecular dynamics simulations. Nanoscale Res. Lett. 4, 444–451 (2009)

Q.H. Tang, F.H. Chen, MD simulation of phase transformations due to nanoscale cutting on silicon monocrystals with diamond tip. J. Phys. D-Appl. Phys. 39, 3674–3679 (2006)

W.C.D. Cheong, L.C. Zhang, Molecular dynamics simulation of phase transformations in silicon monocrystals due to nanoindentation. Nanotechnology 11, 173–180 (2000)

S. Shimada, N. Ikawa, T. Inamura, N. Takezawa, H. Ohmori, T. Sata, Brittle-Ductile transition phenomena in microindentation and micromachining. CIRP Ann.-Manuf. Technol. 44, 523–526 (1995)

M.B. Cai, X.P. Li, M. Rahman, Study of the temperature and stress in nanoscale ductile mode cutting of silicon using molecular dynamics simulation. J. Mater. Process Technol. 192–193, 607–612 (2007)

R. Rentsch, I. Inasaki, Effects of fluids on the surface generation in material removal processes: molecular dynamics simulation. CIRP Ann.-Manuf. Technol. 55, 601–604 (2006)

Y.H. Lin, T.C. Chen, P.F. Yang, S.R. Jian, Y.S. Lai, Atomic-level simulations of nanoindentation-induced phase transformation in mono-crystalline silicon. Appl. Surf. Sci. 254, 1415–1422 (2007)

Z.C. Lin, J.C. Huang, A study of the estimation method of the cutting force for a conical tool under nanoscale depth of cut by molecular dynamics. Nanotechnology 19, 115701 (2008)

L. Zhang, H. Huang, H.W. Zhao, Z.C. Ma, Y.H. Yang, X.L. Hu, The evolution of machining-induced surface of single-crystal FCC copper via nanoindentation. Nanoscale Res. Lett. 8, 211 (2013)

B.R. Lawn, A.G. Evans, D.B. Marshall, Elastic/Plastic indentation damage in ceramics: the median/radial crack system. J. Am. Ceram. Soc. 63, 574 (1980)

C. Francois, Materials Handbook, A Concise Desktop Reference (Springer, Berlin, 2000), p. 348

J. Tersoff, Modelling solid-state chemistry: interatomic potentials for multicomponent system. Phys. Rev. B 39, 5566–5568 (1989)

J. Tersoff, New empirical model for the structural properties of silicon. Phys. Rev. Lett. 56, 632–635 (1986)

L.C. Zhang, H. Tanaka, Z. Liu, in Proceedings of the 19th International Congress on Theoretical Applied Mechanics, Kyoto, Japan, 1996

S. Plimpton, Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995)

LAMMPS Molecular Dynamics Simulator (2011), http://lammps.sandia.gov

J. Jang, M.J. Lance, S. Wen, T. Tsui, G.M. Pharr, Indentation-induced phase transformations in silicon: influences of load, rate and indenter angle on the transformation behavior. Acta Mater. 53, 1759 (2005)

A.P. Gerk, D. Tabor, Indentation hardness and semiconductor-metal transition of germanium and silicon. Nature 271, 732 (1978)

K. Mylvaganam, L.C. Zhang, P. Eyben, J. Mody, W. Vandervorst, Evolution of metastable phases in silicon during nanoindentation: mechanism analysis and experimental verification. Nanotechnology 20, 305705 (2009)

G.M. Pharr, W.C. Oliver, D.R. Clarke, The mechanical behavior of silicon during small-scale indentation. J. Electron. Mater. 19, 881–887 (1990)

H. Olijnyk, Raman scattering in metallic Si and Ge up to 50 GPa. Phys. Rev. Lett. 68, 2232 (1992)

Acknowledgments

This research is funded by the National Natural Science Foundation of China (grant no. 50905073, 51275198, 51105163), Special Projects for Development of National Major Scientific Instruments and Equipments (grant no. 2012YQ030075), National Hi-tech Research and Development Program of China (863 Program) (grant no. 2012AA041206), Key Projects of Science and Technology Development Plan of Jilin Province (grant no. 20110307) and Graduate Innovation Fund of Jilin University (grant no. 20121084).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, L., Zhao, H., Yang, Y. et al. Evaluation of repeated single-point diamond turning on the deformation behavior of monocrystalline silicon via molecular dynamic simulations. Appl. Phys. A 116, 141–150 (2014). https://doi.org/10.1007/s00339-014-8243-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-014-8243-4