Abstract

Zinc oxide (ZnO) nanostructures have been commonly studied for electronic purposes due to their unique piezoelectric and catalytic properties; however, recently, they have been also exploited for biomedical applications. The purpose of this study was to fabricate ZnO-doped poly(urethane) (PU) nanocomposite via one-step electrospinning technique. The utilized nanocomposite was prepared by using colloidal gel composed of ZnO and PU, and the obtained mats were vacuum dried at 60 °C overnight. The physicochemical characterization of as-spun composite nanofibers was carried out by X-ray diffraction pattern, field emission scanning electron microscopy, energy-dispersive X-ray spectroscopy, electron probe microanalysis, and transmission electron microscopy, whereas the thermal behavior was analyzed by thermogravimetric analysis. The viability, attachment, and proliferation of NIH 3T3 mouse fibroblast cells on the ZnO/PU composite nanofibers were analyzed by in vitro cell compatibility test. The morphological features of the cells attached on nanofibers were examined by Bio-SEM. We conclude that the electrospun nanofibrous scaffolds with unique spider nets had good biocompatibility. Cytotoxicity experiments indicated that the mouse fibroblasts could attach to the nanocomposite after being cultured. Thus, the current work demonstrates that the as-synthesized ZnO/PU hybrid nanofibers represent a promising biomaterial to be exploited for various tissue engineering applications.

Similar content being viewed by others

References

Barakat NAM, Kanjwal MA, Sheikh FA, Kim HY (2009) Spider-net within the N6, PVA and PU electrospun nanofiber mats using salt addition: novel strategy in the electrospinning process. Polymer 50:4389–4396

Boretos JH, Pierce WS (1967) Segmented polyurethane: a new elastomer for biomedical applications. Science 158:1481–1487

Ding B, Li CR, Miyauchi Y, Kuwaki O, Shiratori S (2006) Formation of novel 2D polymer nanowebs via electrospinning. Nanotechnology 17:3685–3691

Ding B, Wang MR, Wang XF, Yu JY, Sun G (2010) Electrospun nanomaterials for ultrasensitive sensors. Mater Today 13:16–27

Frenot A, Chronakis IS (2003) Polymer nanofibers assembled by electrospinning. Curr Opinion in Colloid and Interf Sci 8(1):64–75

Ge JJ, Hou H, Li Q, Graham MJ, Greiner A, Reneker DH, Harris FW, Cheng SZD (2004) Assembly of well-aligned multiwalled carbon nanotubes in confined polyacrylonitrile environments: electrospun composite nanofiber sheets. J Am Chem Soc 126:15754–15761

Hou HQ, Reneker DH (2004) Carbon nanotubes on carbon nanofibers: a novel structure based on electrospun polymer nanofibers. Adv Mater 16:69–73

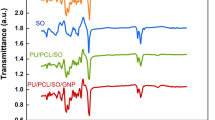

Jiang Z, Yuan KJ, Li SF, Chow WK (2006) Study of FTIR spectra and thermal analysis of polyurethane. Spectrosc Spectr Anal 26:624, In Chinese

Khlystalova TK, Kurganova MN, Demina AI, Petova MB, Tarakanov OG (1986) Hydrolytic stability of polyurethanes in model biological media. Mech Compos Mater 21:763–767

Kidoaki S, Kwon IK, Matsuda T (2006) Structural features and mechanical properties of in situ-bonded meshes of segmented polyurethane electrospun from mixed solvents. J Biomed Mater Res Part B: Appl Biomater 76B:219–229

Kim Y, Yoo J, Kwon B, Hong Y, Lee C, Yi G (2008) Position-controlled ZnO nanoflower arrays grown on glass substrates for electron emitter application. Nanotechnol 19:315202

Kimmer D, Slobodian P, Petras D, Zatloukal M, Olejnik R, Saha P (2009) Polyurethane/multiwalled carbon nanotube nanowebs prepared by an electrospinning process. J Appl Polym Sci 111:2711–2714

Lee J, Kang BS, Hicks B, Chancellor TF, Chu BH, Wang HT, Keselowsky BG, Ren F, Lele TP (2008) The control of cell adhesion and viability by zinc oxide nanorods. Biomaterials 29:3743–3749

Li Z, Yang R, Yu M, Bai F, Li C, Wang Z (2008) Cellular level biocompatibility and biosafety of ZnO nanowires. J Phys Chem C 112:20114–20117

Li XQ, Su Y, Zhou X, Mo XM (2009) Distribution of sorbitan monooleate in poly(l-lactide-co-epsilon-caprolactone) nanofibers from emulsion electrospinning. Colloid Surf B: Biointerfaces 69:221–224

Lieber C, Wang Z (2007) Functional nanowires. MRS Bull 32:99–108

Madhugiri S, Dalton A, Gutierrez J, Ferraris JP, Balkus KJ Jr (2003) Electrospun MEH-PPV/SBA-15 composite nanofibers using a dual syringe method. J Am Chem Soc 125:14531–14538

Mao X, Ding B, Wang MR, Yin YB (2010) Self-assembly of phthalocyanine and polyacrylic acid composite multilayers on cellulose nanofibers. Carbohydr Polym 80:839–844

Pant HR, Bajgai MP, Nam KT, Seo YA, Pandeya DR, Hong ST, Kim HY (2011) Electrospun nylon-6 spider-net like nanofiber mat containing TiO2 nanoparticles: a multifunctional nanocomposite textile material. J Hazardous Mater 185:124–130

Sheikh FA, Kanjwal MA, Saran S, Chung WJ, Kim H (2011) Polyurethane nanofibers containing copper nanoparticles as future materials. Appl Surf Sci 257:3020–3026

Trovati G, Sanches EA, Neto SC, Mascarenhas YP, Chierice GO (2010) Characterization of polyurethane resins by FTIR, TGA, and XRD. J Appl Polym Sci 115:263–268

Wang ZL (2008) Self-powering nanotech. Sci Am 298:82–87

Yoon YI, Moon HS, Lyoo WS, Lee TS, Park WH (2009) Superhydrophobicity of cellulose triacetate fibrous mats produced by electrospinning and plasma treatment. Carbohydr Polym 5:246–250

Zaveri TD, Dolgova NV, Chu BH, Lee J, Wong J, Lele TP, Ren F, Keselowsky BG (2010) Contributions of surface topography and cytotoxicity to the macrophage response to zinc oxide nanorods. Biomaterials 31:2999–3007

Zhan SH, Chen DR, Jiao XL, Liu SS (2007) Facile fabrication of long alpha-Fe2O3, alpha-Fe and gamma-Fe2O3 hollow fibers using sol–gel combined co-elecrospinning technology. J Colloid Interface Sci 308:265–270

Zhou J, Xu N, Wang Z (2006) Dissolving behavior and stability of ZnO wires in biofluids: a study on biodegradability and biocompatibility of ZnO nanostructures. Adv Mater 18:2432–2435

Acknowledgments

This work has been conducted and partly supported by a grant from Next-Generation BioGreen 21 Program (no. PJ008191) and a fund for FTA issues (no. PJ907055), Rural Development Administration, Republic of Korea.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Amna, T., Hassan, M.S., Sheikh, F.A. et al. Zinc oxide-doped poly(urethane) spider web nanofibrous scaffold via one-step electrospinning: a novel matrix for tissue engineering. Appl Microbiol Biotechnol 97, 1725–1734 (2013). https://doi.org/10.1007/s00253-012-4353-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-012-4353-0