Abstract

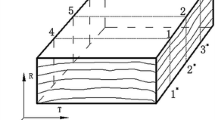

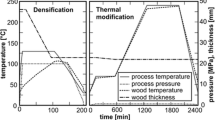

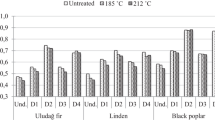

Hydrothermal–mechanical (HTM) treatment is a combined action of temperature, moisture, and mechanical loads. Various kinds of HTM processes have been developed to produce eco-friendly modified wood products. Among these modification technologies, a combination of surface densification and hydrothermal post-treatment is a promising option that can be used to enhance plantation wood properties and generate value-added softwood products. This paper aimed to investigate the transversal dynamic transversal modulus of elasticity (dtMOE) profile and transversal density profile of surface-densified and hydrothermally post-treated needle fir (Abies nephrolepis) wood, and provide a practical guide for the processing optimization of surface-densified and thermally treated low-grade plantation softwood. Needle fir lumbers were surface-densified in an open hot-pressing system, at a compression ratio of 16.1% and two hot-pressing temperatures (160 and 180 °C) for a pressure holding duration of 10 min with a subsequent hydrothermal post-treatment at two temperatures (180 and 200 °C) for 60 min. The transversal dtMOE profiles for six types of specimens (moisture-saturated, conditioned control, and four types of surface-densified specimens) were measured and analyzed by a dynamic thermo-mechanical analysis (DMA) apparatus. A dtMOE gradient variable (G M) was defined herein to quantitatively formulate the dtMOE distribution of the surface-densified and hydrothermally post-treated wood specimens. Upon hot pressing, compressed cell tissues were observed within a 1.0- to 2.0-mm layer beneath the surface of the densified wood. The density peaks of compressed sections were increased to 650–800 kg/m3, compared with the average density of the control specimens being at 350 kg/m3. The dtMOEs of the compressed sections were increased from 650 MPa of the control specimens, to 750–900 MPa, achieving the objective of surface densification. As the temperature of hydrothermal post-treatment increased from 180 to 200 °C, the differences of the dtMOEs between the compressed surface sections and their inner adjacent ones decreased significantly, indicating the effective fixation of the compression deformations. Based on the test results obtained herein, it was concluded that the impact of the hot-pressing temperature and thermal post-treatment temperature over the dtMOE was insignificant. Nevertheless, it was also found that the hydrothermal treatment temperature showed significant influences over the dtMOE difference between the densified surface and its adjacent layer; the possible explanations for these complicated behaviors were also proposed herein.

Similar content being viewed by others

References

Aimene YE, Nairn JA (2015) Simulation of transverse wood compression using a large-deformation, hyperelastic–plastic material model. Wood Sci Technol 49(1):21–39

Ansell MP (2012) Wood: a 45th anniversary of JMS papers. Part 2. Wood modification, fire resistance, carbonization, wood-cement and wood-polymer composites. J Mater Sci 47(2):583–598

Belt T, Rautkari L, Laine K, Hill C (2013) Cupping behavior of surface densified Scots pine wood: the effect of process parameters and correlation with density profile characteristics. J Mater Sci 48(18):6426–6430

Cai JB, Li T (2009) Effects of high temperature heat treatment on the physical and mechanical properties of the compressed poplar lumber (in Chinese). China For Sci Technol 23(3):104–107

Cai JB, Ding T, Yang L, Yang X (2012) Effect of heat treatment and densification on dimensional stability of poplar wood (in Chinese). China Wood Ind 26(5):41–44

Cai JB, Yang X, Cai LP, Shi SQ (2013) Impact of the combination of densification and thermal modification on dimensional stability and hardness of poplar lumber. Drying Technol 31(10):1107–1113

Chen TA, Xu ZY, Wang CM, Li T, Chen LM (2012) Effect of heat treatment on properties of surface-densified Pinus yunnanensis samples (in Chinese). China Wood Ind 26(5):45–47

Ding T, Cai JB, Geng J (2015) Review on thermally modified timber industry and standardization in Europe (in Chinese). China Wood Ind 29(3):26–30

Esteves BM, Pereira HM (2009) Wood modification by heat treatment: a review. BioResources 4(1):370–404

Gong M, Lamason C, Li L (2010) Interactive effect of surface densification and post-heat-treatment on aspen wood. J Mater Process Technol 210(2):293–296

Hill CAS (2006) Wood modification-chemical, thermal and other processes. Wiley, Chichester

Kariz M, Kuzman MK, Sernek M, Hughes M, Rautkari L, Kamke FA, Kutnar A (2017) Influence of temperature of thermal treatment on surface densification of spruce. Eur J Wood Prod 75(1):113–123

Laine K, Rautkari L, Hughes M, Kutnar A (2013a) Reducing the set-recovery of surface densified solid Scots pine wood by hydrothermal post-treatment. Eur J Wood Prod 71(1):17–23

Laine K, Belt T, Rautkari L, Ramsay J, Hill CAS, Hughes M (2013b) Measuring the thickness swelling and set-recovery of densified and thermally modified Scots pine solid wood. J Mater Sci 48(24):8530–8538

Laine K, Segerholm K, Wålinder M, Rautkari L, Ormondroyd G, Hughes M, Dennis Jones (2014) Micromorphological studies of surface densified wood. J Mater Sci 49(5):2027–2034

Laine K, Segerholm K, Wålinder M, Rautkari L, Hughes M (2016a) Wood densification and thermal modification: hardness, set-recovery and micromorphology. Wood Sci Technol 50(5):883–894

Laine K, Segerholm K, Wålinder M, Rautkari L, Hughes M, Lankveld C (2016b) surface densification of acetylated wood. Eur J Wood Prod 74(6):829–835

Li J, Liu YX, Liu JL (2000) Study on the fixation of compressive deformation of wood in the transversal direction by high temperature steam treatment (in Chinese). J Northeast For Univ 28(4):4–8

Liao L, Tu D, Li C, Zhou Q, Zhang S, Wu X (2013) Effects of heat treatment on physical-mechanical properties of E.urophylla × E.camaldulensis (in Chinese). J Central South Univ For Technol 33(5):128–131

Navi P, Pizzi A (2015) Property changes in thermo-hydro-mechanical processing. Holzforschung 69(7):863–873

Popescu MC, Lisa G, Froidevaux J, Navi P, Popescu CM (2014) Evaluation of the thermal stability and set recovery of thermo-hydro-mechanically treated lime (Tilia cordata) wood. Wood Sci Technol 48(1):85–97

Rautkari L, Laine K, Laflin N, Hughes M (2011) Surface modification of Scots pine: the effect of process parameters on the through thickness density profile. J Mater Sci 46(14):4780–4786

Rautkari L, Laine K, Kutnar A, Medved S, Hughes M (2013) Hardness and density profile of surface densified and thermally modified Scots pine in relation to degree of densification. J Mater Sci 48(6):2370–2375

Tjeerdsma BF, Boonstra M, Pizzi A, Tekely P, Militz H (1998) Characterisation of thermally modified wood: molecular reasons for wood performance improvement. Holz Roh Werkst 56(3):149–153

Tu DY, Du C, Zhou QF, Yang SS, Lao YM, Dong H (2012) Poplar wood flooring surface densification (in Chinese). China Wood Ind 26(4):46–48

Wang FH (2005) Rheology of wooden materials. Northeast Forestry University Press, Harbin (in Chinese)

Welzbacher CR, Wehsener J, Rapp AO, Haller P (2008) Thermo-mechanical densification combined with thermal modification of Norway spruce in industrial scale-dimensional stability and durability aspects. Holz Roh- Werkst 66(1):39–49

Windeisen E, Bächle H, Zimmer B, Wegener G (2009) Relations between chemical changes and mechanical properties of thermally treated wood 10th EWLP, Stockholm, Sweden, August 25–28, 2008. Holzforschung 63(6):773–778

Zhan JF (2008) Bound moisture diffusion and drying rheology of larch wood under conventional drying (in Chinese). Ph. D thesis, Northeast Forestry University

Zhan JF, Avramidis S (2016) Needle fir wood modified by surface densification and thermal post-treatment: hygroscopicity and swelling behavior. Eur J Wood Prod 74(1):49–56

Zhan JF, Avramidis S (2017) Impact of conventional drying and thermal post-treatment on the residual stresses and shape deformations of larch lumber. Drying Technol 35(1):15–24

Zhan JF, Cao J, Gu JY, Zhan XR, Chen W, Liu ZJ, Liu B, Ma HJ (2015) Surface-densification and post high-temperature hydrothermal treatment of the Abies nephrolepis lumber (in Chinese). J Nanjing For Univ (Natural Sciences Edition) 39(3):119–124

Zhao ZS, Liu YX, Shen J (2010) Dynamic thermo-mechanical properties of strengthened poplar wood sheets by compression perpendicular to grain (in Chinese). J Northeast For Univ 38(12):62–64

Acknowledgements

The authors gratefully acknowledge the Natural Science Foundation of Heilongjiang Province, PR China (No: C2015053), the Fundamental Research Funds for the Central Universities of China (Northeast Forestry University, No: DL13CB17), and the innovative practice project for the undergraduate (Northeast Forestry University, national level), for providing the financial support for this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhan, Jf., Avramidis, S. Transversal mechanical properties of surface-densified and hydrothermally modified needle fir wood. Wood Sci Technol 51, 721–738 (2017). https://doi.org/10.1007/s00226-017-0909-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-017-0909-6