Abstract

Wood exhibits a pronounced time dependent deformation behavior which is usually split into ‘viscoelastic’ creep at constant moisture content (MC) and ‘mechano-sorptive’ creep in varying MC conditions. Experimental determination of model rheological parameters on a material level remains a serious challenge, and diversity of experimental methods makes published results difficult to compare. In this study, a cantilever experimental setup is proposed for creep tests because of its close analogy with the mechanical behavior of wood during drying. Creep measurements were conducted at different load levels (LL) under controlled temperature and humidity conditions. Radial specimens of white spruce wood [Picea glauca (Moench.) Voss.] with dimensions of 110 mm in length (R), 25 mm in width (T), and 7 mm in thickness (L) were used. The influence of LL and MC on creep behavior of wood was exhibited. In constant MC conditions, no significant difference was observed between creep of tensile and compressive faces of wood cantilever. For load not greater than 50% of the ultimate load, the material exhibited a linear viscoelastic creep behavior at the three equilibrium moisture contents considered in the study. The mechano-sorptive creep after the first sorption phase was several times greater than creep at constant moisture conditions. Experimental data were fitted with numerical simulation of the global rheological model developed by authors for rheological parameter identification.

Similar content being viewed by others

References

Armstrong LD, Kingston RST (1962) The effect of moisture content changes on the deformation of wood under stress. Aust J Appl Sci 13(4):259–276

Bažant ZP (1985) Constitutive equation of wood at variable humidity and temperature. Wood Sci Technol 19:159–177

Bodig J, Jayne BA (1982) Mechanics of wood and wood composites. Van Nostrand Reinhold Co., New York, 712 p

Grossman P (1976) Requirements for a model that exhibits mechano-sorptive behaviour. Wood Sci Technol 10:163–168

Guissi A (2003) Mesure des coefficients du tenseur d’élasticité du bois par essais de compression sur éprouvettes normalisées. Mémoire de Maîtrise, Faculté de Foresterie et de Géodésie, Université Laval, Québec, Canada, 137 p

Hanhijärvi A (1999) Deformation properties of Finnish spruce and pine wood in tangential and radial directions in association to high temperature drying. Part 2. Experimental results under constant conditions (viscoelastic creep). Holz Roh Werkst 57(5):365–372

Hanhijärvi A (2000a) Deformation properties of Finnish spruce and pine wood in tangential and radial directions in association to high temperature drying. Part 3. Experimental results under drying conditions (mechano-sorptive creep). Holz Roh Werkst 58(1–2):63–71

Hanhijärvi A (2000b) Deformation properties of Finnish spruce and pine wood in tangential and radial directions in association to high temperature drying. Part 4. Modeling. Holz Roh Werkst 58(4):211–216

Hearmon RFS, Paton JW (1964) Moisture content changes on creep of wood. For Prod J 14:357–359

Hisada T (1979) Creep and set behaviour of wood related to kiln drying. II. Effect of stress level on tensile creep of wood during drying. Mokuzai Gakkaishi 25(11):697–706

Hisada T (1980) Creep and set behaviour of wood related to kiln drying. IV. Effect of stress level on compressive creep and set of wood during drying. Mokuzai Gakkaishi 26(8):519–526

Jessome AP (1977) Résistance et propriétés connexes des bois indigènes du Canada. Rapport technique de foresterie 21, Lab. des produits forestiers de l'Est, Ottawa, Canada, 37 p

Leicester RH (1971) A rheological model for mechano-sorptive deflections of beams. Wood Sci Technol 5:211–220

Mårtensson A (1988) Tensile behavior of hardboard under combined mechanical and moisture loading. Wood Sci Technol 22:129–142

Moutee M, Fafard M, Fortin Y, Laghdir A (2005) Modeling the creep behavior of wood cantilever loaded at free end during drying. Wood Fiber Sci 37(3):521–534

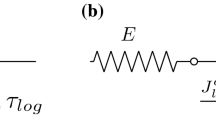

Moutee M, Fortin Y, Fafard M (2007) A global rheological model of wood cantilever as applied to wood drying. Wood Sci Technol 41(3):209–234

Muszyński L, Lagana R, Davids W, Shaler SM (2005) Comments on the experimental methodology for quantitative determination of the hygro-mechanical properties of wood. Holzforschung 59(2):232–239

Navi P, Pittet V, Plummer CJG (2002) Transient moisture effects on wood creep. Wood Sci Technol 36:447–462

Ranta-Maunus A (1975) The viscoelasticity of wood at varying moisture content. Wood Sci Technol 9:189–205

Ranta-Maunus A (1993) Rheological behaviour of wood in directions perpendicular to the grain. Mater Struct 26:362–369

Schniewind AP (1968) Recent progress in the study of the rheology of wood. Wood Sci Technol 2:188–206

Svensson S (1995) Strain and shrinkage force in wood under kiln drying conditions. I: measuring strain and shrinkage under controlled climate conditions. Equipment and preliminary results. Holzforschung 49(4):363–368

Svensson S (1996) Strain and shrinkage force in wood under kiln drying conditions. II: strain, shrinkage and stress measurements under controlled climate conditions. Holzforschung 50(5):463–469

Svensson S, Mårtensson A (1999) Simulation of drying stresses in wood. I: comparison between one- and two-dimensional models. Holz Roh Werkst 57(2):129–136

Svensson S, Toratti T (2002) Mechanical response of wood perpendicular to grain when subjected to changes of humidity. Wood Sci Technol 36(2):145–156

Toratti T, Svensson S (2000) Mechano-sorptive experiments perpendicular to grain under tensile and compressive loads. Wood Sci Technol 34(4):317–326

Wu Q, Milota MR (1996) Mechano-sorptive deformation of Douglas-fir specimens under tangential tensile stress during moisture adsorption. Wood Fiber Sci 28(1):128–132

Zhuoping S (2005) The variable parameter rheological model of wood. Wood Sci Technol 39(1):19–26

Acknowledgments

The authors are grateful for the financial support of this research from Natural Sciences and Engineering Research Council of Canada (No. 224297) and Forintek Canada Corp.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moutee, M., Fortin, Y., Laghdir, A. et al. Cantilever experimental setup for rheological parameter identification in relation to wood drying. Wood Sci Technol 44, 31–49 (2010). https://doi.org/10.1007/s00226-009-0274-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-009-0274-1