Abstract

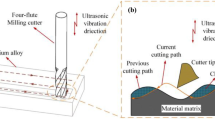

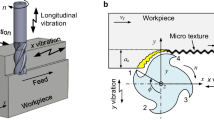

The objective of this paper is to investigate the effects of assisted ultrasonic vibration on the surface roughness of machined surfaces in micro-end-milling. Series of slot-milling experiments were conducted with aluminum alloy as workpiece material. The surface roughness of slot bottom surface and vertical side wall surface of slot was studied, respectively. It is found that surface roughness of the machined slot bottom surface could increase to varying degrees because of ultrasonic vibration in most of the studied cases, and this deterioration becomes more apparent when large feed per tooth and low-spindle speed were adopted. As for the vertical side wall surface of the slot, there is an obvious improvement of surface roughness when ultrasonic vibration is applied. Based on analysis of variance analysis, further study indicates that the surface roughness of vertical side wall surface of the slot is determined by several key parameters including spindle speed, feed per tooth and amplitude in ultrasonic vibration-assisted milling. An optimal combination of these parameters is of great benefit to achieving small surface roughness.

Similar content being viewed by others

References

Kumabe J, Sabuzawa T (1971) Study on the precision drilling of wood (1st report)—profile analysis of drilled hole. J JSPE 37(2):98–104, in Japanese

Jin M, Murakawa M (2001) Development of a practical ultrasonic vibration cutting tool system. J Mater Process Technol 113:342–347

Zhou M, Wang XJ, Ngoi BKA, Gan JGK (2002) Brittle- ductile transition in the diamond cutting of glasses with the aid of ultrasonic vibration. J Mater Process Technol 121:243–251

Xiao M, Sato K, Karube S, Soutome T (2003) The effect of tool nose radius in ultrasonic vibration cutting of hard metal. Int J Mach Tools Manuf 43:1375–1382

Gan J, Wang X, Zhou M, Ngoi B, Zhong Z (2003) Ultraprecision diamond turning of glass with ultrasonic vibration. Int J Adv Manuf Technol 21:952–955

Shamoto E, Moriwaki T (1999) Ultraprecision diamond cutting of hardenedsteel by applying elliptical vibration cutting. Ann CIRP 48(1):441–444

Ma CX, Shamoto E, Moriwaki T, Wang LJ (2004) Study of machining accuracy in ultrasonic elliptical vibration cutting. Int J Mach Tools Manuf 44:1305–1310

Liu K, Li XP, Rahman M, Liu XD (2004) Study of ductile mode cutting in grooving of tungsten carbide with and without ultrasonic vibration assistance. Int J Adv Manuf Technol 24:389–394

Zhong ZW, Lin G (2006) Ultrasonic assisted turning of an aluminium-based metal matrix composite reinforced with SiC particles. Int J Adv Manuf Technol 27:1077–1081

Nath C, Rahman M, Andrew SSK (2007) A study on ultrasonic vibration cutting of low alloy steel. J Mater Process Technol 192–193:159–165

Nath C, Rahman M (2008) Effect of machining parameters in ultrasonic vibration cutting. Int J Mach Tools Manuf 48:965–974

Pujana J, Rivero A, Celaya A, Lopez de Lacalle LN (2009) Analysis of ultrasonic-assisted drilling of Ti6A14V. Int J Mach Tools Manuf 49:500–508

Chern GL, Chang YC (2006) Using two-dimensional vibration cutting for micro-milling. Int J Mach Tools Manuf 46:659–666

Shen XH, Zhang JH, Yin TJ, Dong CJ (2010) A study on cutting force in micro end milling with ultrasonic vibration. Adv Mat Res 97–101:1910–1914

Kumabe J (1985) Fundamentals and application of vibration cutting. China Machine Press, Beijing

Xiao M, Karube S, Soutome T, Sato K (2002) Analysis of chatter suppression in vibration cutting. Int J Mach Tools Manuf 42:1677–1685

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, XH., Zhang, J., Xing, D.X. et al. A study of surface roughness variation in ultrasonic vibration-assisted milling. Int J Adv Manuf Technol 58, 553–561 (2012). https://doi.org/10.1007/s00170-011-3399-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3399-y