Abstract

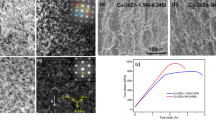

The morphology, crystallography, chemistry, and distribution of the phases in commercial high-tensile strength brasses containing manganese and silicon with compositions conforming to U.S.A. Specifications C67300 (Cu-35Zn-2.5Mn-lSi) and C67400 (Cu-35Zn-2.5Mn-lSi-l.5Al) have been studied. The wrought and cast microstructures of both types of alloys consist of the copper-rich feea phase, ordered B2β’ phase, and a manganese silicide Mn5Si3, with the crystal structure D88. Particles of Mn5Si3 are distributed uniformly in the as-cast alloy C67300 but tend to concentrate at theβ′ boundaries in alloy C67400. Studies of the development of the microstructure show that Mn5Si3 particles form from the liquid and are also precipitated from solid solution. During cooling, the α phase precipitates at a higher temperature in alloy C67300 (800 °C) than in alloy C67400 (500 °C); nucleation of the α phase occurs on Mn5Si3 particles in alloy C67400. Tiny Mn5Si3 precipitates are formed in both alloys upon quenching from temperatures near the solidus. When the quenched specimens are tempered at temperatures between 400 °C and 500 CC, all of theβ′ phase transforms to α in alloy C67300, while in alloy C67400, α precipitation occurs at theβ′ boundaries and shows a Widmanstätten morphology.

Similar content being viewed by others

References

Source Book on Copper and Copper Alloys, ASM, Metals Park, OH, 1979, p. 29.

High Tensile Brasses, Copper Development Association, Potters Bar, CDA Pub. 42, 1986.

K.V. Varli, N.V. Edneral, A.I. Leikin, Yu.A. Shakov, and B.V. Tyurin:Metalloved. Term. Obrab. Met., 1978, vol. 6, pp. 34–37.

F. Hasan, A. Jahanafrooz, G.W. Lorimer, and N. Ridley:Metall. Trans. A, 1982, vol. 13A, pp. 1337–45.

G. Cliff and G.W. Lorimer:J. Microscopy, 1975, vol. 103, pp. 203–07.

ASTM X-Ray Powder Diffraction Data File 3-1039.

Y.A. Chang, J.P. Neuman, A. Mikula, and D. Goldberg:Phase Diagrams and Thermodynamic Properties of Ternary Copper Metal Systems, International Copper Research Association, NSRDS, U.S.A., 1979, pp. 543–48, 558-65, and 669-75.

H. Watanabe, N. Kono, and M. Gonda:J. Japan lnst. Metals, 1972, vol. 36, pp. 297–305.

H. Pops:Trans. TMS-AIME, 1964, vol. 230, pp. 813–20.

E.G. West:Copper and Its Alloys, Ellis Horwood, Chichester, 1982.

Author information

Authors and Affiliations

Additional information

Formerly with the Manchester Materials Science Centre.

Rights and permissions

About this article

Cite this article

Sun, Y.S., Lorimer, G.W. & Ridley, N. Microstructure of high-tensile strength brasses containing silicon and manganese. Metall Trans A 20, 1199–1206 (1989). https://doi.org/10.1007/BF02647401

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02647401