Abstract

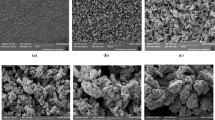

The paper focuses on thermal and electrical properties of copper–graphite composites. Copper–graphite composites in the range of 0–50 vol% of graphite were prepared from the mixture of copper and graphite powder by the powder metallurgy method. Such composites combine high thermal and electrical conductivities provided by copper matrix and low thermal expansion coefficient and lubricating properties due to the graphite phase. We model thermal and electrical conductivities and thermal expansion coefficient using methods of micromechanics in connection with the material microstructure and measure these quantities experimentally to compare with the results of modeling. Cross-property connections between thermal and electrical properties of the composites are established and experimentally verified.

Similar content being viewed by others

References

Tong XC (2011) Advanced materials for thermal management of electronic packaging. Springer, New York

Dorfman S, Fuks D (1996) Diffusivity of carbon in the copper matrix. Influence of alloying. Compos A Appl Sci Manuf 27(9):697–701

Whitehouse AF, Warwick CM, Clyne TW (1991) Electrical resistivity of copper reinforced with short carbon fibres. J Mater Sci 26(22):6176–6182. doi:10.1007/BF01113901

Kúdela S, Schweighofer A, Kunkela J (1992) Pseudoalloy-type composite materials produced by pressure infiltration. Compos Manuf 3(1):43–46

Emmer S, Bielek J, Havalda A (1993) Cooper-graphite composite material for application to sliding electrical contacts. Le Journal de Physique IV 3(C7):C7–C1799

Yasar I, Canakci A, Arslan F (2007) The effect of brush spring pressure on the wear behaviour of copper–graphite brushes with electrical current. Tribol Int 40(9):1381–1386

Kováčik J, Emmer Š, Bielek J (2008) Effect of composition on friction coefficient of Cu–graphite composites. Wear 265(3):417–421

Klement M, Guth G, Lott O, Nagel A, Schneider G (2015) Synthesis and quantitative characterization of novel copper-graphite composite materials for use as electrical sliding contacts. Pract Metallogr 52(1):21–37

Glatz J, Vrable DL (1993) Applications of advanced composites for satellite packaging for improved electronic component thermal management. Acta Astronaut 29(7):527–535

Firkowska I, Boden A, Boerner B, Reich S (2015) The origin of high thermal conductivity and ultralow thermal expansion in copper-graphite composites. Nano Lett 15(7):4745–4751

Ling Z, Zhang Z, Shi G, Fang X, Wang L, Gao X, Fang Y, Xua T, Wang S, Liu X (2014) Review on thermal management systems using phase change materials for electronic components, Li-ion batteries and photovoltaic modules. Renew Sustain Energy Rev 31:427–438

Korab J, Štefánik P, Kavecký Š, Šebo P, Korb G (2002) Thermal conductivity of unidirectional copper matrix carbon fibre composites. Compos A Appl Sci Manuf 33(4):577–581

Hutsch T, Schubert T, Weißgärber T, Kieback B (2010) Innovative metal-graphite composites as thermally conducting materials. In Proceedings of the powder metallurgy world congress and exhibition. PM2010, pp. 361–368

Kováčik J, Emmer Š, Bielek J (2016) Cross-property connections for copper–graphite composites. Acta Mech 227(1):105–112

Kováčik J, Bielek J (1996) Electrical conductivity of Cu/graphite composite material as a function of structural characteristics. Scripta Mater 35(2):151–156

Tritt TM (2004) Thermal conductivity: theory, properties, and applications. Springer Science & Business Media

Kachanov M, Sevostianov I (2005) On quantitative characterization of microstructures and effective properties. Int J Solids Struct 42(2):309–336

Horii H, Nemat-Nasser S (1983) Overall moduli of solids with microcracks: load-induced anisotropy. J Mech Phys Solids 31(2):155–171

Sevostianov I, Kachanov M (1999) Compliance tensors of ellipsoidal inclusions. Int J Fract 96(1):3–7

Sevostianov I, Kachanov M (2002) Explicit cross-property correlations for anisotropic two-phase composite materials. J Mech Phys Solids 50(2):253–282

Sevostianov I, Giraud A (2013) Generalization of Maxwell homogenization scheme for elastic material containing inhomogeneities of diverse shape. Int J Eng Sci 64:23–36

Sevostianov I (2012) On the thermal expansion of composite materials and cross-property connection between thermal expansion and thermal conductivity. Mech Mater 45:20–33

Levin VM (1967) On the coefficients of thermal expansion of heterogeneous material. Mechanics of Solids 2:58–61. (English transl. of Izvestia AN SSSR, Mekhanika Tverdogo Tela)

Rosen BW, Hashin Z (1970) Effective thermal expansion coefficients and specific heats of composite materials. Int J Eng Sci 8(2):157–173

Hashin Z (1983) Analysis of composite materials—a survey. J Appl Mech 50(3):481–505

Markov KZ (2000) Elementary micromechanics of heterogeneous media. In Heterogeneous media. Birkhäuser Boston, pp. 1–162

Sevostianov I, Kováčik J, Simančík F (2006) Elastic and electric properties of closed-cell aluminum foams: cross-property connection. Mater Sci Eng, A 420(1):87–99

Sevostianov I, Kachanov M (2012) Effective properties of heterogeneous materials: proper application of the non-interaction and the “dilute limit” approximations. Int J Eng Sci 58:124–128

Chowdhury A, Christov CI (2010) Fast Legendre spectral method for computing the perturbation of a gradient temperature field in an unbounded region due to the presence of two spheres. Numer Methods Partial Differ Equ 26(5):1125–1145

Clausius R (1879) The mechanical theory of heat. Macmillan

Bruggeman DAG (1935) Berechnung verschiedener physikalisher Konstanten von heterogenen Substanzen. I. Dielectrizitätkonstanten und Leitfähigkeiten der Mischkörper aus isotropen Substanzen. Ann Physik Leipzig 24:636–679

Bruggeman DAG (1937) Berechnung verschiedener physikalisher Konstanten von heterogenen Substanzen. III. Die elastische Konstanten der Quaiisotropen Mischkörper aus isotropen Substanzen. Ann Physik Leipzig 29:160–178

Hashin Z (1988) The differential scheme and its application to cracked materials. J Mech Phys Solids 36(6):719–734

Mori T, Tanaka K (1973) Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall 21(5):571–574

Benveniste Y (1986) On the Mori-Tanaka’s method in cracked bodies. Mech Res Commun 13(4):193–201

Maxwell JC (1873) A treatise on electricity and magnetism. Clarendon Press, Oxford

Bristow JR (1960) Microcracks, and the static and dynamic elastic constants of annealed and heavily cold-worked metals. Br J Appl Phys 11(2):81

Berryman JG, Milton GW (1988) Microgeometry of random composites and porous media. J Phys D Appl Phys 21(1):87

Gibiansky LV, Torquato S (1993) Link between the conductivity and elastic moduli of composite materials. Phys Rev Lett 71(18):2927

Gibiansky LV, Torquato S (1995) Rigorous link between the conductivity and elastic moduli of fibre-reinforced composite materials. Philos Trans R Soc Lond A Math Phys Eng Sci 353(1702):243–278

Chen T (1993) Thermoelastictic properties and conductivity of composites reinforced by spherically anisotropic particles. Mech Mater 14:257–268

Sevostianov I, Kachanov M (2008) Contact of rough surfaces: a simple model for elasticity, conductivity and cross-property connections. J Mech Phys Solids 56(4):1380–1400

Sevostianov I, Kachanov M (2009) Connections between elastic and conductive properties of heterogeneous materials. Adv Appl Mech 42:69–252

Kunin IA (1983) Elastic medium with random fields of inhomogeneities. In Elastic media with microstructure II. Springer, Berlin, pp. 165–228

Kanaun SK, Levin VM (2008) Self-consistent methods for composites, Vol 1: static problems. Springer

Kováčik J, Emmer Š (2011) Thermal expansion of Cu/graphite composites: effect of copper coating. Kovove Materialy 49:411–416

Gillis PP (1984) Calculating the elastic constants of graphite. Carbon 22(4/5):387–391

Acknowledgements

Financial support from the FP7 Project TAMER IRSES-GA-2013-610547 and New Mexico Space Grant Consortium contained in the NASA Cooperative Agreement NNX13AB19A to New Mexico State University are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Tensor basis in the space of transversely isotropic fourth-rank tensors. Representation of certain transversely isotropic tensors in terms of the tensor basis

The operations of analytic inversion and multiplication of fourth-rank tensors are conveniently done in terms of special tensorial bases that are formed by the combinations of unit tensor \( \delta_{ij} \) and one or two orthogonal unit vectors [44, 45]. In the case of the transversely isotropic elastic symmetry, the following basis is most convenient (it differs slightly from the one used in [45]):

where \( \theta_{ij} = \delta_{ij} - m_{i} m_{j} \) and \( \varvec{m} = m_{1} \varvec{e}_{1} + m_{2} \varvec{e}_{2} + m_{3} \varvec{e}_{3} \) is a unit vector along the axis of transverse symmetry.These tensors form the closed algebra with respect to the operation of (non-commutative) multiplication (contraction over two indices):

The inverse of any fourth-rank tensor \( {\varvec{X}} \), as well as the product \( {\varvec{X}}\,{\varvec{:}}\,{\varvec{Y}} \) of two such tensors are readily found in the closed form, as soon as the representation in the basis

are established. Indeed: (a) inverse tensor \( \varvec{X}^{ - 1} \) defined by \( X_{ijmn}^{ - 1} X_{mnkl} \) \( = \left( {X_{ijmn} X_{mnkl}^{ - 1} } \right)\; = J_{ijkl} \) is given by

where \( \Delta = 2\left( {X_{1} X_{6} - X_{3} X_{4} } \right) \). (b) product of two tensors \( {\varvec{X}}\,{\varvec{:}}\,{\varvec{Y}} \) (tensor with \( ijkl \) components equal to \( X_{ijmn} Y_{mnkl} \)) is

If \( x_{3} \) is the axis of transverse symmetry, general transversely isotropic fourth-rank tensor, being represented in this basis

has the following components:

In particular:

-

Tensor of elastic compliances of the isotropic material \( S_{ijkl} = \sum {s_{m} T_{ijkl}^{m} } \) has the following components

$$ s_{1} = \frac{1 - \nu }{{4G\left( {1 + \nu } \right)}};s_{2} = \frac{1}{2G};s_{3} = s_{4} = \frac{ - \nu }{{2G\left( {1 + \nu } \right)}};s_{5} = \frac{1}{G};s_{6} = \frac{1}{{2G\left( {1 + \nu } \right)}} $$(54) -

Tensor of elastic stiffness of the isotropic material by \( C_{ijkl} = \sum {c_{m} T_{ijkl}^{m} } \) has components

$$ c_{1} = \lambda + G;c_{2} = 2G;c_{3} = c_{4} = \lambda ;c_{5} = 4G;c_{6} = \lambda + 2G, $$(55)where \( \lambda = {{2G\nu } \mathord{\left/ {\vphantom {{2G\nu } {\left( {1 - 2\nu } \right)}}} \right. \kern-0pt} {\left( {1 - 2\nu } \right)}}. \)

-

Unit fourth-rank tensors are represented in the form

$$ J_{ijkl}^{\left( 1 \right)} = {{\left( {\delta_{ik} \delta_{lj} + \delta_{il} \delta_{kj} } \right)} \mathord{\left/ {\vphantom {{\left( {\delta_{ik} \delta_{lj} + \delta_{il} \delta_{kj} } \right)} 2}} \right. \kern-0pt} 2} = \frac{1}{2}T_{ijkl}^{1} + T_{ijkl}^{2} + 2T_{ijkl}^{5} + T_{ijkl}^{6} $$(56)$$ J_{ijkl}^{\left( 2 \right)} = \delta_{ij} \delta_{kl} = T_{ijkl}^{1} + T_{ijkl}^{3} + T_{ijkl}^{4} + T_{ijkl}^{6} $$(57) -

Compliance contribution tensor H of a spheroidal inhomogeneity, with bulk and shear moduli \( K_{1} \) and \( G_{1} \), is represented in this basis by coefficients (see [20], for example):

$$ \begin{aligned} h_{1} = \frac{1}{{2\Delta }}\left[ {\delta K + \frac{4}{3} \delta G + q_{6} } \right];h_{2} = \frac{1}{{2\delta G + q_{2} }};h_{3} = h_{4} = - \frac{1}{\Delta }\left[ {\delta K - \frac{2}{3}\delta G + q_{3} } \right]; \hfill \\ h_{5} = \frac{4}{{4\delta G + q_{5} }};h_{6} = \frac{2}{\Delta }\left[ {K + \frac{1}{3}\delta G+ q_{1} } \right] \hfill \\ \end{aligned} $$(58)where the following notations are used

$$ \delta K = {{K_{1} K_{0} } \mathord{\left/ {\vphantom {{K_{1} K_{0} } {\left( {K_{0} - K_{1} } \right)}}} \right. \kern-0pt} {\left( {K_{0} - K_{1} } \right)}};\begin{array}{*{20}c} {} & {\delta G = } \\ \end{array} {{G_{1} G_{0} } \mathord{\left/ {\vphantom {{G_{1} G_{0} } {\left( {G_{0} - G_{1} } \right)}}} \right. \kern-0pt} {\left( {G_{0} - G_{1} } \right)}} $$$$ \Delta = 2\left[ {3\delta G\delta K + \delta K\left( {q_{1} + q_{6} - 2q_{3} } \right) + \frac{\delta G}{3}\left( {4q_{1} + q_{6} + 4q_{3} } \right) + \left( {q_{1} q_{6} - q_{3}^{2} } \right)} \right]\; $$(59)and

$$ \begin{aligned} q_{1} = G\left[ {4\kappa - 1 - 2\left( {3\kappa - 1} \right)f_{0} - 2\kappa f_{1} } \right],q_{2} = 2G\left[ {1 - \left( {2 - \kappa } \right)f_{0} - \kappa f_{1} } \right], \hfill \\ q_{3} = q_{4} = 2G\left[ {\left( {2\kappa - 1} \right)f_{0} + 2\kappa f_{1} } \right],q_{5} = 4G\left( {f_{0} + 4\kappa f_{1} } \right) \hfill \\ q_{6} = 8G\left( {\kappa f_{0} - \kappa f_{1} } \right), \hfill \\ \end{aligned} $$(60)where \( \kappa \), \( f_{0} \left( \gamma \right) \), and \( f_{1} \left( \gamma \right) \) are given by (18) and (9).

Rights and permissions

About this article

Cite this article

Mazloum, A., Kováčik, J., Emmer, Š. et al. Copper–graphite composites: thermal expansion, thermal and electrical conductivities, and cross-property connections. J Mater Sci 51, 7977–7990 (2016). https://doi.org/10.1007/s10853-016-0067-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0067-5