Investigating Approaches of Integrating BIM, IoT, and Facility Management for Renovating Existing Buildings: A Review

Abstract

:1. Introduction

2. BIM and Existing Buildings

3. Integrating BIM and IoT

3.1. Developments of BIM Implementation

- Maintenance and repair of the life cycle of O&M and FM result in injuries caused by falling, electric shocks, crushing, and other workers and facility users.

- According to [65] and recently to [66], a large portion of total energy worldwide has been spent on the current operations of the existing building. Hence, utilizing energy efficiently is indeed a prime concern in reducing stress on the energy system and benefits the environment. In this sense, BIM can significantly improve energy analysis through simulation [67].

- The fragmented O&M causes energy simulation very difficult leading to a possible error-prone decision in the renovation along with issues such as safety, repair, and maintenance [68].

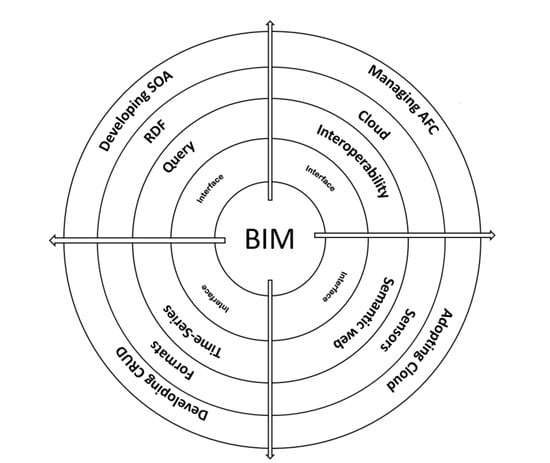

3.2. Principles of BIM–IoT Integration

3.3. Stages of BIM–IoT Integration

3.3.1. Stage 1: Establishing Open Storage

3.3.2. Stage 2: Gathering BIM and Live Data

3.3.3. Stage 3: Feeding the Live Data into the Open Storage

4. BIM–IoT and Big-Data Principle

5. BIM and IoT Devices Integration Approach

- BIM acts as a data repository for contextual information including building geometry while IoT acts as static and soft information that is gathered from occupancy patterns. In addition, IoT is responsible for scheduling data like social media, feedback originated from FM and occupant interactions, and external sources of information such as weather forecast and financial pricing [96].

- The continuous sensor readings and traditional time-series data (known as time-series data) are stored in a well-structured relational database queried effectively under Structured Query Language (SQL) [97,98]. The time-series data is provided by sensors while API is responsible to move data belongs to BMI models constructing tools. The database is to clarify the connection of a two-way connection between virtual objects and physical sensors where data is passing between the database and BIM using APIs [99].

- The third component is about integration between contextual information and time-series data.

- Integrating BIM and IoT requires an interface technically known as Application Program Interface (API) to correlate data from the sensor and BIM model with evolving database and the two-way importing/exporting data, and queries processing [100].

5.1. BIM–IoT Architecture

5.2. Query Language Approach

6. Query Languages

6.1. Semantic Web Approach

6.2. Hybrid (Semantic Web and Relational Database) Approach

6.3. Limitation and Challenging of BIM–IoT Integration

6.3.1. Limitations

6.3.2. Sensors Challenges

6.4. Devising a New Approach for IoT–BIM Integration

6.4.1. Framework of BIM and Sensor Integration

6.4.2. Implementing Service-Oriented Architecture

7. Summary of Previous Empirical Research

8. Contribution

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 2D/3D | Two/Three-Dimensional |

| 3V’s | Volume, Variety, Velocity |

| ACM | Association for Computing Machinery |

| AEC | Architecture, Engineering and Construction |

| AECO | Architecture, Engineering, Construction, and Operation |

| AI | Artificial Intelligence |

| API | Application Programming Interface |

| ASCE | American Society of Civil Engineers |

| BDA | Big Data Analytics |

| BDE | Big Data Engineering |

| BHIMM | Heritage Information Modelling and Management |

| BIM | Building Information Modelling |

| BIMQL | BIM Query Language |

| CAD | computer-aided design |

| CPS | Cyber–Physical System |

| CRUD | Create, Read, Update and Delete. |

| DAG | Directed Acrylic Graphs |

| DG | Digital Photogrammetry |

| DM | Data Mining |

| DOC/XLS/PPT | Microsoft Office Format |

| DWG | Drawing File Format. |

| DXF | Drawing Exchange Format |

| EMR | Elastic MapReduce |

| FM | Facility Management |

| GPR | Ground Penetration Radar |

| GPRS | General Packet Radio Service |

| GUI | Graphic User Interface |

| Hadoop | High Availability Distributed Object-Oriented Platform |

| HBase™ | Hadoop Base. |

| HBIM | Historic Building Information Modelling |

| HVAC | Heating, Ventilation, and Air Conditioning |

| ICT | Information and Communication Technologies |

| IFC | Industry Foundation Classes |

| ifcOWL | Industry Foundation Classes OWL |

| ifcXML | Industry Foundation Classes XML |

| IO | Input/output data |

| IoT | Internet of Things |

| IRT | Infrared thermography images |

| JPEG | Image Format |

| KM Analysis | Knowledge Management Analysis |

| LC | Life Cycle |

| LIFE | Lean and Injury-Free |

| LoD | Level of Detail |

| MR | Mappers and Reducers |

| NDT | Non-Destructive Testing |

| NIST | National Institute of Standards and Technology |

| NLQ | Natural Language Query |

| O&M | Operation and Maintenance |

| OntoFM | Ontology Facility Management |

| OWL | Web Ontology Language |

| RDF | Resource Description Format |

| REST | Representational State Transfer |

| RFIDs | Radio Frequency Identifications |

| RGB | Red, Green, Blue |

| RM)/MPG | Video Format |

| RVT (Revit) | Software for BIM |

| SAREF | Smart Appliances Reference ontology |

| SOA | Service-Oriented-Architecture |

| SPARQL | Query Language and Protocol. |

| SQL | Structured Query Language |

| SSN | Semantic Sensor Network |

| TLS | Terrestrial Laser Scanner |

| UAS | Unmanned Aerial Systems |

| XQuery | XML Query) |

References

- Xu, X.; Mumford, T.; Zou, P.X. Life-cycle building information modelling (BIM) engaged framework for improving building energy performance. Energy Build. 2021, 231, 110496. [Google Scholar] [CrossRef]

- Wang, C.; Cho, Y.K.; Kim, C. Automatic BIM component extraction from point clouds of existing buildings for sustainability applications. Autom. Constr. 2015, 56, 1–13. [Google Scholar] [CrossRef]

- Ansah, M.K.; Chen, X.; Yang, H.; Lu, L.; Lam, P.T. A review and outlook for integrated BIM application in green building assessment. Sustain. Cities Soc. 2019, 48, 101576. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, Z.; Chang, R.; Li, Y. Building Information Modeling (BIM) for green buildings: A critical review and future directions. Autom. Constr. 2017, 83, 134–148. [Google Scholar] [CrossRef]

- Gao, J.; Zhong, X.; Cai, W.; Ren, H.; Huo, T.; Wang, X.; Mi, Z. Dilution effect of the building area on energy intensity in urban residential buildings. Nat. Commun. 2019, 10, 4944. [Google Scholar] [CrossRef]

- Pourzolfaghar, Z.; McDonnell, P.; Helfert, M. Barriers to benefit from integration of building information with live data from IOT devices during the facility management phase. In Proceedings of the CITA BIM Gathering 2015, Dublin, Ireland, 23–24 November 2017. [Google Scholar]

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of Things (IoT): A vision, architectural elements, and future directions. Future Gener. Comput. Syst. 2013, 29, 1645–1660. [Google Scholar] [CrossRef] [Green Version]

- Čolaković, A.; Hadžialić, M. Internet of Things (IoT): A review of enabling technologies, challenges, and open research issues. Comput. Netw. 2018, 144, 17–39. [Google Scholar] [CrossRef]

- Dehury, C.K.; Sahoo, P.K. Design and implementation of a novel service management framework for IoT devices in cloud. J. Syst. Softw. 2016, 119, 149–161. [Google Scholar] [CrossRef]

- Tang, S.; Shelden, D.R.; Eastman, C.M.; Pishdad-Bozorgi, P.; Gao, X. A review of building information modeling (BIM) and the internet of things (IoT) devices integration: Present status and future trends. Autom. Constr. 2019, 101, 127–139. [Google Scholar] [CrossRef]

- Teizer, J.; Wolf, M.; Golovina, O.; Perschewski, M.; Propach, M.; Neges, M.; König, M. Internet of Things (IoT) for integrating environmental and localization data in Building Information Modeling (BIM). In ISARC Proceedings of the International Symposium on Automation and Robotics in Construction (Vol. 34); Vilnius Gediminas Technical University: Vilnius, Lithuania, 2017. [Google Scholar]

- Amano, K.; Lou, E.C.; Edwards, R. Integration of point cloud data and hyperspectral imaging as a data gathering methodology for refurbishment projects using Building Information Modelling (BIM). J. Facil. Manag. 2019, 17, 57–75. [Google Scholar] [CrossRef]

- Ozturk, G.B. Interoperability in building information modeling for AECO/FM industry. Autom. Constr. 2020, 113, 103122. [Google Scholar] [CrossRef]

- Akcamete, A.; Akinci, B.; Garrett, J.H., Jr. Motivation for computational support for updating building information models (BIMs). In Computing in Civil Engineering; ASCE: Reston, VA, USA, 2009; pp. 523–532. [Google Scholar]

- Arayici, Y. Towards Building Information Modelling for Existing Structures. Structural Survey. Available online: http://usir.salford.ac.uk/id/eprint/12473/ (accessed on 27 February 2021).

- Armesto, J.; Lubowiecka, I.; Ordóñez, C.; Rial, F.I. FEM modeling of structures based on close range digital photogrammetry. Autom. Constr. 2009, 18, 559–569. [Google Scholar] [CrossRef]

- Klein, L.; Li, N.; Becerik-Gerber, B. Imaged-based verification of as-built documentation of operational buildings. Autom. Constr. 2012, 21, 161–171. [Google Scholar] [CrossRef]

- ISO 22263:2008. Organization of Information About Construction Works—Framework for Management of Project Information, International Standard; ISO: Geneva, Switzerland, 2008. [Google Scholar]

- Bilal, M.; Oyedele, L.O.; Qadir, J.; Munir, K.; Ajayi, S.O.; Akinade, O.O.; Pasha, M. Big Data in the construction industry: A review of present status, opportunities, and future trends. Adv. Eng. Inform. 2016, 30, 500–521. [Google Scholar] [CrossRef]

- Zhao, X. A scientometric review of global BIM research: Analysis and visualization. Autom. Constr. 2017, 80, 37–47. [Google Scholar] [CrossRef]

- Ding, K.; Shi, H.; Hui, J.; Liu, Y.; Zhu, B.; Zhang, F.; Cao, W. Smart steel bridge construction enabled by BIM and Internet of Things in industry 4.0: A framework. In Proceedings of the 2018 IEEE 15th International Conference on Networking, Sensing and Control (ICNSC), Zhuhai, China, 27–29 March 2018; IEEE: New York, NY, USA, 2018; pp. 1–5. [Google Scholar]

- Fang, Y.; Cho, Y.K.; Durso, F.; Seo, J. Assessment of operator’s situation awareness for smart operation of mobile cranes. Autom. Constr. 2018, 85, 65–75. [Google Scholar] [CrossRef]

- Rahimian, F.P.; Seyedzadeh, S.; Oliver, S.; Rodriguez, S.; Dawood, N. On-demand monitoring of construction projects through a game-like hybrid application of BIM and machine learning. Autom. Constr. 2020, 110, 103012. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Peng, Y.; Xue, F.; Fang, J.; Zou, W.; Luo, H.; Ng, S.T.; Lu, W.; Shen, G.Q.; Huang, G.Q. Prefabricated construction enabled by the Internet-of-Things. Autom. Constr. 2017, 76, 59–70. [Google Scholar] [CrossRef]

- Xu, G.; Li, M.; Chen, C.H.; Wei, Y. Cloud asset-enabled integrated IoT platform for lean prefabricated construction. Autom. Constr. 2018, 93, 123–134. [Google Scholar] [CrossRef]

- Li, C.Z.; Xue, F.; Li, X.; Hong, J.; Shen, G.Q. An Internet of Things-enabled BIM platform for on-site assembly services in prefabricated construction. Autom. Constr. 2018, 89, 146–161. [Google Scholar] [CrossRef]

- Mostafa, S.; Kim, K.P.; Tam, V.W.; Rahnamayiezekavat, P. Exploring the status, benefits, barriers and opportunities of using BIM for advancing prefabrication practice. Int. J. Constr. Manag. 2020, 20, 146–156. [Google Scholar] [CrossRef]

- Pärn, E.A.; Edwards, D.J. Conceptualising the FinDD API plug-in: A study of BIM-FM integration. Autom. Constr. 2017, 80, 11–21. [Google Scholar] [CrossRef]

- Habibi, S. Micro-climatization and real-time digitalization effects on energy efficiency based on user behavior. Build. Environ. 2017, 114, 410–428. [Google Scholar] [CrossRef]

- Cheng, M.Y.; Chiu, K.C.; Hsieh, Y.M.; Yang, I.T.; Chou, J.S.; Wu, Y.W. BIM integrated smart monitoring technique for building fire prevention and disaster relief. Autom. Constr. 2017, 84, 14–30. [Google Scholar] [CrossRef]

- Dixit, M.K.; Venkatraj, V.; Ostadalimakhmalbaf, M.; Pariafsai, F.; Lavy, S. Integration of facility management and building information modeling (BIM). Facilities 2019, 37, 455–483. [Google Scholar] [CrossRef]

- Kim, K.; Cho, Y.; Zhang, S. Integrating work sequences and temporary structures into safety planning: Automated scaffolding-related safety hazard identification and prevention in BIM. Autom. Constr. 2016, 70, 128–142. [Google Scholar] [CrossRef]

- Eastman, C.M.; Teicholz, P.; Sacks, R.; Liston, K. Handbook BIM: A Guide to Building Information Modeling for Owners, Managers, Architects, Engineers, Contractors, and Fabricators; Wiley: Hoboken, NJ, USA, 2008. [Google Scholar]

- Nawari, N.O.; Ravindran, S. Blockchain and building information modeling (BIM): Review and applications in post-disaster recovery. Buildings 2019, 9, 149. [Google Scholar] [CrossRef] [Green Version]

- Shepherd, D. The BIM Management Handbook; Routledge: London, UK, 2019. [Google Scholar]

- Bruno, N.; Roncella, R. HBIM for conservation: A new proposal for information modeling. Remote Sens. 2019, 11, 1751. [Google Scholar] [CrossRef] [Green Version]

- Koh, J.B. Metadata Models and Methods for Smart Buildings. Ph.D. Thesis, University of California San Diego, San Diego, CA, USA, 2020. [Google Scholar]

- Murphy, M.; McGovern, E.; Pavia, S. Historic building information modelling (HBIM). Struct. Surv. 2009, 27, 311–327. [Google Scholar] [CrossRef] [Green Version]

- Bruno, S.; De Fino, M.; Fatiguso, F. Historic Building Information Modelling: Performance assessment for diagnosis-aided information modelling and management. Autom. Constr. 2018, 86, 256–276. [Google Scholar] [CrossRef]

- Ciribini, A.L.C.; Ventura, S.M.; Paneroni, M. BIM methodology as an integrated approach to heritage conservation management. Wit Trans. Built Environ. 2015, 149, 265–276. [Google Scholar]

- Ilter, D.; Ergen, E. BIM for building refurbishment and maintenance: Current status and research directions. Struct. Surv. 2015, 33, 228–256. [Google Scholar] [CrossRef]

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings—Literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef] [Green Version]

- Oreni, D.; Brumana, R.; Georgopoulos, A.; Cuca, B. HBIM for conservation and management of built heritage: Towards a library of vaults and wooden bean floors. ISPRS 2013, 5, W1. [Google Scholar] [CrossRef] [Green Version]

- Sun, Z.; Xie, J.; Zhang, Y.; Cao, Y. As-Built BIM for a fifteenth-century Chinese brick structure at various LoDs. ISPRS Int. J. Geo-Inf. 2019, 8, 577. [Google Scholar] [CrossRef] [Green Version]

- Fai, S.; Graham, K.; Duckworth, T.; Wood, N.; Attar, R. Building information modelling and heritage documentation. In Proceedings of the 23rd International Symposium, International Scientific Committee for Documentation of Cultural Heritage (CIPA), Prague, Czech Republic, 11–16 September 2011; pp. 12–16. [Google Scholar]

- McArthur, J.J. A building information management (BIM) framework and supporting case study for existing building operations, maintenance and sustainability. Procedia Eng. 2015, 118, 1104–1111. [Google Scholar] [CrossRef] [Green Version]

- Chiesa, G. ICT, Data and Design Issues. In Technological Paradigms and Digital Eras; Springer: Cham, Switzerland, 2020; pp. 1–38. [Google Scholar]

- Cruz, I.F.; Xiao, H. Ontology driven data integration in heterogeneous networks. In Complex Systems in Knowledge-Based Environments: Theory, Models and Applications; Springer: Berlin/Heidelberg, Germany, 2009; pp. 75–98. [Google Scholar]

- Hu, Z.Z.; Tian, P.L.; Li, S.W.; Zhang, J.P. BIM-based integrated delivery technologies for intelligent MEP management in the operation and maintenance phase. Adv. Eng. Softw. 2018, 115, 1–16. [Google Scholar] [CrossRef]

- Costin, A.; Adibfar, A.; Hu, H.; Chen, S.S. Building Information Modeling (BIM) for transportation infrastructure–Literature review, applications, challenges, and recommendations. Autom. Constr. 2018, 94, 257–281. [Google Scholar] [CrossRef]

- Zhai, Y.; Chen, K.; Zhou, J.X.; Cao, J.; Lyu, Z.; Jin, X.; Shen, G.Q.; Lu, W.; Huang, G.Q. An Internet of Things-enabled BIM platform for modular integrated construction: A case study in Hong Kong. Adv. Eng. Inform. 2019, 42, 100997. [Google Scholar] [CrossRef]

- Hossain, M.A.; Yeoh, J.K.W. BIM for Existing Buildings: Potential Opportunities and Barriers. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 371, p. 012051. [Google Scholar]

- Motawa, I.; Almarshad, A. A knowledge-based BIM system for building maintenance. Autom. Constr. 2013, 29, 173–182. [Google Scholar] [CrossRef]

- Ghaffarianhoseini, A.; Tookey, J.; Ghaffarianhoseini, A.; Naismith, N.; Azhar, S.; Efimova, O.; Raahemifar, K. Building Information Modelling (BIM) uptake: Clear benefits, understanding its implementation, risks and challenges. Renew. Sustain. Energy Rev. 2017, 75, 1046–1053. [Google Scholar] [CrossRef]

- Gimenez, L.; Robert, S.; Suard, F.; Zreik, K. Automatic reconstruction of 3D building models from scanned 2D floor plans. Autom. Constr. 2016, 63, 48–56. [Google Scholar] [CrossRef]

- NBS. National BIM Report 2015; Royal Institute of British Architects: London, UK, 2015. [Google Scholar]

- Lu, Q.; Lee, S. Image-based technologies for constructing as-is building information models for existing buildings. J. Comput. Civ. Eng. 2017, 31, 04017005. [Google Scholar] [CrossRef]

- Laefer, D.F.; Truong-Hong, L. Toward automatic generation of 3D steel structures for building information modelling. Autom. Constr. 2017, 74, 66–77. [Google Scholar] [CrossRef]

- Lucas, J.D. Managing the Facility with Lifecycle Information. J. Curr. Issues Media Telecommun. 2015, 7, 13–36. [Google Scholar]

- Teicholz, E. Bridging the AEC technology gap. IFMA Facil. Manag. J. 2004, 587, 588. [Google Scholar]

- IFMA. Exploring the Current Trends and Future Outlook for Facility Management; Facility Management Forecast 2011; The International Facility Management Association: Houston, TX, USA, 2011; ISBN 1-883176-84-0. [Google Scholar]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef] [Green Version]

- Ma, Z.; Cooper, P.; Daly, D.; Ledo, L. Existing building retrofits: Methodology and state-of-the-art. Energy Build. 2012, 55, 889–902. [Google Scholar] [CrossRef]

- Shaikh, P.H.; Shaikh, F.; Sahito, A.A.; Uqaili, M.A.; Umrani, Z. An Overview of the Challenges for Cost-Effective and Energy-Efficient Retrofits of the Existing Building Stock. In Cost-Effective Energy Efficient Building Retrofitting; Woodhead Publishing: Swaston, UK, 2017; pp. 257–278. [Google Scholar]

- Asadi, E.; Da Silva, M.G.; Antunes, C.H.; Dias, L. Multi-objective optimization for building retrofit strategies: A model and an application. Energy Build. 2012, 44, 81–87. [Google Scholar] [CrossRef]

- Huang, Z.; Ge, J.; Zhao, K.; Shen, J. Post-evaluation of energy consumption of the green retrofit building. Energy Procedia 2019, 158, 3608–3613. [Google Scholar] [CrossRef]

- Salvalai, G.; Sesana, M.M.; Iannaccone, G. Deep renovation of multi-storey multi-owner existing residential buildings: A pilot case study in Italy. Energy Build. 2017, 148, 23–36. [Google Scholar] [CrossRef]

- Xiaonuan, S.; SiuYu, S.L. Existing buildings’ operation and maintenance: Renovation project of Chow Yei Ching Building at the University of Hong Kong. Int. J. Low-Carbon Technol. 2014, 10, 393–404. [Google Scholar] [CrossRef] [Green Version]

- Pärn, E.A.; Edwards, D.J.; Sing, M.C. The building information modelling trajectory in facilities management: A review. Autom. Constr. 2017, 75, 45–55. [Google Scholar] [CrossRef] [Green Version]

- Kassem, M.; Kelly, G.; Dawood, N.; Serginson, M.; Lockley, S. BIM in facilities management applications: A case study of a large university complex. Built Environ. Proj. Asset. Manag. 2015, 5, 261–277. [Google Scholar] [CrossRef] [Green Version]

- Bortoluzzi, B.; Efremov, I.; Medina, C.; Sobieraj, D.; McArthur, J.J. Automating the creation of building information models for existing buildings. Autom. Constr. 2019, 105, 102838. [Google Scholar] [CrossRef]

- Dixit, M.K.; Venkatraj, V. Integrating facility management functions in building information modeling (BIM): A review of key issues and challenges. In Proceedings of the International Research Conference (IRC) 2017: Shaping Tomorrow’s Built Environment Conference Proceedings, Salford, UK, 11–12 September 2017; pp. 597–608. [Google Scholar]

- Carli, R.; Dotoli, M.; Pellegrino, R.; Ranieri, L. Using multi-objective optimization for the integrated energy efficiency improvement of a smart city public buildings’ portfolio. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering (CASE), Gothenburg, Sweden, 24–28 August 2015; pp. 21–26. [Google Scholar]

- Peng, Y.; Lin, J.R.; Zhang, J.P.; Hu, Z.Z. A hybrid data mining approach on BIM-based building operation and maintenance. Build. Environ. 2017, 126, 483–495. [Google Scholar] [CrossRef]

- Quattrini, R.; Pierdicca, R.; Morbidoni, C. Knowledge-based data enrichment for HBIM: Exploring high-quality models using the semantic-web. J. Cult. Herit. 2017, 28, 129–139. [Google Scholar] [CrossRef]

- Wanner, E. On Remembering, Forgetting, and Understanding Sentences: A Study of the Deep Structure Hypothesis; Walter de Gruyter GmbH Co KG: Berlin, Germany, 2019; Volume 170. [Google Scholar]

- Pourzolfaghar, Z.; Helfert, M. Integration of buildings information with live data from IoT devices. In Connected Environments for the Internet of Things; Springer: Cham, Switzerland, 2017; pp. 169–185. [Google Scholar]

- Dexeus, C.R. The deepening effects of the digital revolution. In The Future of Tourism; Springer: Cham, Switzerland, 2019; pp. 43–69. [Google Scholar]

- Eadie, R.; Browne, M.; Odeyinka, H.; McKeown, C.; McNiff, S. BIM implementation throughout the UK construction project lifecycle: An analysis. Autom. Constr. 2013, 36, 145–151. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhang, S.; Li, Y.; Wang, Y.; Yang, B.; Wang, L. An augmented Mapreduce framework for building information modeling applications. In Proceedings of the 2014 IEEE 18th International Conference on Computer Supported Cooperative Work in Design (CSCWD), Hsinchu, Taiwan, 21–23 May 2014; IEEE: New York, NY, USA, 2014; pp. 283–288. [Google Scholar]

- Lin, J.R.; Hu, Z.Z.; Zhang, J.P.; Yu, F.Q. A Natural-Language-Based Approach to Intelligent Data Retrieval and Representation for Cloud BIM. Comput. Aided Civ. Infrastruct. Eng. 2016, 31, 18–33. [Google Scholar] [CrossRef]

- Zheng, R.; Jiang, J.; Hao, X.; Ren, W.; Xiong, F.; Ren, Y. bcBIM: A blockchain-based big data model for BIM modification audit and provenance in mobile cloud. Math. Probl. Eng. 2019, 2019. [Google Scholar] [CrossRef] [Green Version]

- Hofmann, E. Big data and supply chain decisions: The impact of volume, variety and velocity properties on the bullwhip effect. Int. J. Prod. Res. 2017, 55, 5108–5126. [Google Scholar] [CrossRef]

- Provost, F.; Fawcett, T. Data Science for Business: What You Need to Know about Data Mining and Data-Analytic Thinking; O’Reilly Media, Inc.: Newton, MA, USA, 2013. [Google Scholar]

- Ray, P.D. Pervasive, Domain and Situational-Aware, Adaptive, Automated, and Coordinated Big Data Analysis, Contextual Learning and Predictive Control of Business and Operational Risks and Security. U.S. Patent No. 10,210,470, 19 February 2019. [Google Scholar]

- Matsunaga, F.T.; Brancher, J.D.; Busto, R.M. Data mining techniques and tasks for multidisciplinary applications: A systematic review. ReABTIC 2015, 1. [Google Scholar] [CrossRef]

- Dean, J.; Ghemawat, S. MapReduce: Simplified data processing on large clusters. Commun. ACM 2008, 51, 107–113. [Google Scholar] [CrossRef]

- Wang, Q.; Lee, B.; Murray, N.; Qiao, Y. MR-IoT: An information centric MapReduce framework for IoT. In Proceedings of the 2018 15th IEEE Annual Consumer Communications & Networking Conference (CCNC), Las Vegas, NV, USA, 12–15 January 2018; pp. 1–6. [Google Scholar]

- Qadir, J.; Ahad, N.; Mushtaq, E.; Bilal, M. SDNs, clouds, and big data: New opportunities. In Proceedings of the 2014 12th International Conference on Frontiers of Information Technology, Islamabad, Pakistan, 17–19 December 2014; pp. 28–33. [Google Scholar]

- Agneeswaran, V.S. Big Data Analytics beyond Hadoop: Real-Time Applications with Storm, Spark, and More Hadoop Alternatives; FT Press: Upper Saddle River, NJ, USA, 2014. [Google Scholar]

- Watson, H.J. Update tutorial: Big Data analytics: Concepts, technology, and applications. Commun. Assoc. Inf. Syst. 2019, 44, 365–379. [Google Scholar]

- Lu, J.; Chen, Y.; Herodotou, H.; Babu, S. Speedup your analytics: Automatic parameter tuning for databases and big data systems. Proc. Vldb Endow. 2019, 12, 1970–1973. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Chang, P.; Hu, Z.; Fu, H.; Yan, L. A Spark-based Ant Lion Algorithm for Parameters Optimization of Random Forest in Credit Classifi.cation. In Proceedings of the 2019 IEEE 3rd Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chengdu, China, 15–17 March 2019; pp. 992–996. [Google Scholar]

- Singh, D.; Reddy, C.K. A survey on platforms for big data analytics. J. Big Data 2015, 2, 8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karau, H.; Konwinski, A.; Wendell, P.; Zaharia, M. Learning Spark: Lightning-Fast Big Data Analysis; O’Reilly Media, Inc.: Newton, MA, USA, 2015. [Google Scholar]

- Garofalo, M.; Botta, A.; Ventre, G. Astrophysics and big data: Challenges, methods, and tools. Proc. Int. Astron. Union 2016, 12, 345–348. [Google Scholar] [CrossRef] [Green Version]

- Corry, E.; O’Donnell, J.; Curry, E.; Coakley, D.; Pauwels, P.; Keane, M. Using semantic web technologies to access soft AEC data. Adv. Eng. Inform. 2014, 28, 370–380. [Google Scholar] [CrossRef]

- Kazmi, A.H.; O’grady, M.J.; Delaney, D.T.; Ruzzelli, A.G.; O’hare, G.M. A review of wireless-sensor-network-enabled building energy management systems. ACM Trans. Sens. Netw. (TOSN) 2014, 10, 66. [Google Scholar] [CrossRef]

- Woo, J.H.; Peterson, M.A.; Gleason, B. Developing a virtual campus model in an interactive game-engine environment for building energy benchmarking. J. Comput. Civ. Eng. 2016, 30, C4016005. [Google Scholar] [CrossRef]

- Lingappa, P.R. Master Applet for Secure Remote Payment Processing. U.S. Patent No. 10,592,899, 17 March 2020. [Google Scholar]

- Abu-Tair, M.; Djahel, S.; Perry, P.; Scotney, B.; Zia, U.; Carracedo, J.M.; Sajjad, A. Towards Secure and Privacy-Preserving IoT Enabled Smart Home: Architecture and Experimental Study. Sensors 2020, 20, 6131. [Google Scholar] [CrossRef] [PubMed]

- Motamedi, A.; Hammad, A.; Asen, Y. Knowledge-assisted BIM-based visual analytics for failure root cause detection in facilities management. Autom. Constr. 2014, 43, 73–83. [Google Scholar] [CrossRef]

- Singh, G.; Solanki, A. An algorithm to transform natural language into SQL queries for relational databases. Selforganizology 2016, 3, 100–116. [Google Scholar]

- Mazairac, W.; Beetz, J. BIMQL–An open query language for building information models. Adv. Eng. Inform. 2013, 27, 444–456. [Google Scholar] [CrossRef]

- Schreiber, G.; Akkermans, H.; Anjewierden, A.; Shadbolt, N.R.; de Hoog, R.; Van de Velde, W.; Wielinga, B.J. Knowledge Engineering and Management: The CommonKADS Methodology; MIT Press: Cambridge, MA, USA, 2000. [Google Scholar]

- Chen, L.; Shadbolt, N.R.; Goble, C.A. A semantic web-based approach to knowledge management for grid applications. IEEE Trans. Knowl. Data Eng. 2006, 19, 283–296. [Google Scholar] [CrossRef]

- Dibley, M.; Li, H.; Rezgui, Y.; Miles, J. An ontology framework for intelligent sensor-based building monitoring. Autom. Constr. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Curry, E.; O’Donnell, J.; Corry, E.; Hasan, S.; Keane, M.; O’Riain, S. Linking building data in the cloud: Integrating cross-domain building data using linked data. Adv. Eng. Inform. 2013, 27, 206–219. [Google Scholar] [CrossRef] [Green Version]

- Hu, S.; Corry, E.; Curry, E.; Turner, W.J.; O’Donnell, J. Building performance optimisation: A hybrid architecture for the integration of contextual information and time-series data. Autom. Constr. 2016, 70, 51–61. [Google Scholar] [CrossRef]

- Fedushko, S.; Ustyianovych, T. Operational Intelligence Software Concepts for Continuous Healthcare Monitoring and Consolidated Data Storage Ecosystem. In International Conference on Computer Science, Engineering and Education Applications; Springer: Cham, Switzerland, 2020; pp. 545–557. [Google Scholar]

- Fedushko, S.; Ustyianovych, T.; Gregus, M. Real-time high-load infrastructure transaction status output prediction using operational intelligence and big data technologies. Electronics 2020, 9, 668. [Google Scholar] [CrossRef] [Green Version]

- Ogasawara, G.H.; Tso, M.M. Hybrid Data Management System and Method for Managing Large, Varying Datasets. U.S. Patent No. 9,396,290, 19 July 2016. [Google Scholar]

- McGlinn, K.; Yuce, B.; Wicaksono, H.; Howell, S.; Rezgui, Y. Usability evaluation of a web-based tool for supporting holistic building energy management. Autom. Constr. 2017, 84, 154–165. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Kassem, M.; Ciribini, A.L.C.; Bolpagni, M. A proposed approach integrating DLT, BIM, IOT and smart contracts: Demonstration using a simulated installation task. In International Conference on Smart Infrastructure and Construction 2019 (ICSIC) Driving Data-Informed Decision-Making; ICE Publishing: London, UK, 2019; pp. 275–282. [Google Scholar]

- Sacks, R.; Eastman, C.; Lee, G.; Teicholz, P. BIM Handbook: A Guide to Building Information Modeling for Owners, Designers, Engineers, Contractors, and Facility Managers; John Wiley Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Dallasega, P.; Rauch, E.; Linder, C. Industry 4.0 as an enabler of proximity for construction supply chains: A systematic literature review. Comput. Ind. 2018, 99, 205–225. [Google Scholar] [CrossRef]

- Dave, B.; Buda, A.; Nurminen, A.; Främling, K. A framework for integrating BIM and IoT through open standards. Autom. Constr. 2018, 95, 35–45. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Carli, R.; Dotoli, M. Robust optimal energy management of a residential microgrid under uncertainties on demand and renewable power generation. IEEE Trans. Autom. Sci. Eng. 2020, 1–20. [Google Scholar] [CrossRef]

- Li, C.T.; Cheng, J.C.; Chen, K. Top 10 technologies for indoor positioning on construction sites. Autom. Constr. 2020, 118, 103309. [Google Scholar] [CrossRef]

- Blaauwbroek, N.; Nguyen, P.H.; Konsman, M.J.; Shi, H.; Kamphuis, R.I.; Kling, W.L. Decentralized resource allocation and load scheduling for multicommodity smart energy systems. IEEE Trans. Sustain. Energy 2015, 6, 1506–1514. [Google Scholar] [CrossRef] [Green Version]

- Maskuriy, R.; Selamat, A.; Ali, K.N.; Maresova, P.; Krejcar, O. Industry 4.0 for the construction industry—How ready is the industry? Appl. Sci. 2019, 9, 2819. [Google Scholar] [CrossRef] [Green Version]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Lavy, S.; Jawadekar, S. A case study of using BIM and COBie for facility management. Int. J. Facil. Manag. 2014, 5, 109458840. [Google Scholar]

- Koch, C.; Hansen, G.K.; Jacobsen, K. Missed opportunities: Two case studies of digitalization of FM in hospitals. Facilities 2019, 37, 381–394. [Google Scholar] [CrossRef]

- Shirowzhan, S.; Sepasgozar, S.M.; Edwards, D.J.; Li, H.; Wang, C. BIM compatibility and its differentiation with interoperability challenges as an innovation factor. Autom. Constr. 2020, 112, 103086. [Google Scholar] [CrossRef]

- Son, H.; Kim, C.; Turkan, Y. Scan-to-BIM-an overview of the current state of the art and a look ahead. In ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction; IAARC Publications: London, UK, 2015; Volume 32, p. 1. [Google Scholar]

- Hess, M.; Petrovic, V.; Yeager, M.; Kuester, F. Terrestrial laser scanning for the comprehensive structural health assessment of the Baptistery di San Giovanni in Florence, Italy: An integrative methodology for repeatable data acquisition, visualization and analysis. Struct. Infrastruct. Eng. 2018, 14, 247–263. [Google Scholar] [CrossRef]

- Fricker, P.; Sandau, R.; Walker, A.S. Development of an airborne digital sensor for photogrammetric and remote sensing applications. In Proceedings of the ASPRS Annual Conference, Washington, DC, USA, 21–26 May 2000. [Google Scholar]

- Dai, F.; Feng, Y.; Hough, R. Photogrammetric error sources and impacts on modeling and surveying in construction engineering applications. Vis. Eng. 2014, 2, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Tang, P.; Huber, D.; Akinci, B.; Lipman, R.; Lytle, A. Automatic reconstruction of as-built building information models from laser-scanned point clouds: A review of related techniques. Autom. Constr. 2010, 19, 829–843. [Google Scholar] [CrossRef]

- Hernandez-Marin, S.; Wallace, A.M.; Gibson, G.J. Bayesian analysis of lidar signals with multiple returns. IEEE Trans. Pattern Anal. Mach. Intell. 2007, 29, 2170–2180. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maser, K.R. Condition assessment of transportation infrastructure using ground-penetrating radar. J. Infrastruct. Syst. 2007, 2, 94–101. [Google Scholar] [CrossRef]

- Maierhofer, C. Nondestructive evaluation of concrete infrastructure with ground penetrating radar. J. Mater. Civ. Eng. 2003, 15, 287–297. [Google Scholar] [CrossRef]

- Solla, M.; Gonçalves, L.M.S.; Gonçalves, G.; Francisco, C.; Puente, I.; Providência, P.; Gaspar, F.; Rodrigues, H. A Building Information Modeling Approach to Integrate Geomatic Data for the Documentation and Preservation of Cultural Heritage. Remote Sens. 2020, 12, 4028. [Google Scholar] [CrossRef]

- Isikdag, U. Enhanced building information models. In Enhanced Building Information Models: Using IoT Services and Integration Patterns; Springer International Publishing : New York, NY, USA, 2015; pp. 13–24. [Google Scholar] [CrossRef]

- Thu Nguyen, Integration of BIM and IoT to Improve Building Performance for OCCUPANTS’ perspectives. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2016.

- Rowley, J. The wisdom hierarchy: Representations of the DIKW hierarchy. J. Inf. Sci. 2007, 33, 163–180. [Google Scholar] [CrossRef] [Green Version]

- Ufuk-Gökçe, H.; Umut-Gökçe, K. Integrated system platform for energy efficient building operations. J. Comput. Civ. Eng. 2014, 28, 05014005. [Google Scholar] [CrossRef]

- Pishdad-Bozorgi, P.; Gao, X.; Eastman, C.; Self, A.P. Planning and developing facility management-enabled building information model (FM-enabled BIM). Autom. Constr. 2018, 87, 22–38. [Google Scholar] [CrossRef]

- Khalid, M.U.; Bashir, M.K.; Newport, D. Development of a building information modelling (BIM)-based real-time data integration system using a building management system (BMS). In Building Information Modelling, Building Performance, Design and Smart Construction; Springer: Cham, Switzerland, 2017; pp. 93–104. [Google Scholar]

- Desogus, G.; Quaquero, E.; Sanna, A.; Gatto, G.; Tagliabue, L.C.; Rinaldi, S.; Ciribini, A.L.C.; Di Giuda, G.; Villa, V. Preliminary performance monitoring plan for energy retrofit: A cognitive building: The “Mandolesi Pavillon” at the University of Cagliari. In Proceedings of the 2017 AEIT International Annual Conference, Cagliari, Italy, 20–22 September 2017; pp. 1–6. [Google Scholar]

- Hefnawy, A.; Bouras, A.; Cherifi, C. IoT for smart city services: Lifecycle approach. In Proceedings of the International Conference on Internet of things and Cloud Computing, Cambridge, UK, 23 February–22 March 2016; pp. 1–9. [Google Scholar]

- Shabanzadeh, M.; Sheikh-El-Eslami, M.K.; Haghifam, M.R. A medium-term coalition-forming model of heterogeneous DERs for a commercial virtual power plant. Appl. Energy 2016, 169, 663–681. [Google Scholar] [CrossRef]

- Kanan, R.; Elhassan, O.; Bensalem, R. An IoT-based autonomous system for workers’ safety in construction sites with real-time alarming, monitoring, and positioning strategies. Autom. Constr. 2018, 88, 73–86. [Google Scholar] [CrossRef]

| Construction Type | Reference |

|---|---|

| Operation and Monitoring | [21,22,23] |

| Logistic and Management | [24,25,26,27] |

| Facility Management | [28,29,30,31] |

| Health and Safety | [23,24,25,26,27,28,29,30,31,32] |

| Specifications | Purpose | Methodology | Main Points | Conclusions | |

|---|---|---|---|---|---|

| [12] Integration of point cloud data and hyperspectral imaging as a data gathering methodology for refurbishment projects using Building Information Modelling (BIM). Journal of Facilities Management, 17(1), 57–75 | Integration of point cloud data and hyperspectral imaging as a data gathering methodology for refurbishment projects using building information modelling (BIM). Journal of Facilities Management. | Laser scanning can be used to collect geometrical and spatial information in the form of a 3D point cloud, and this technique is already used. However, as a point cloud representation does not contain any semantic information or geometrical context, such point cloud data must refer to external sources of data, such as building specification and construction materials, to be in used in BIM. | Hyperspectral imaging techniques can be applied to provide both spectral and spatial information of scenes as a set of high-resolution images. Integrating of a 3D point cloud into hyperspectral images would enable accurate identification and classification of surface materials and would also convert the 3D representation to BIM | This integrated approach was applied in facilities management and construction to improve the efficiency and automation of the data transition from building pathology to BIM. This study integrates laser scanning and hyperspectral imaging. In addition, the study uses a new integration technique which is applied for the first time in the context of buildings. | |

| [19] Big Data in the construction industry: A review of present status, opportunities, and future trends. Advanced engineering informatics, 30(3), 500–521. | Integrate big data in the construction industry to provide new opportunities and future trends. | Related works were reviewed based on publications of the databases of American Association of Civil Engineers (ASCE), Institute of Electrical and Electronics Engineers (IEEE), Association of Computing Machinery (ACM), and Elsevier Science Direct Digital Library. | This paper fills the void and presents a wide-ranging interdisciplinary review of literature of fields such as statistics, data mining and warehousing, machine learning, and Big Data Analytics in the context of the construction industry. | The current state of adoption of Big Data in the construction industry was reviewed. Future potential of Big Data across the multiple domain-specific sub-areas of the construction industry. The review concludes that Big Data could have potential approach to treat the potential pitfalls associated with Big Data adoption in the industry. | |

| [122] Towards a semantic Construction Digital Twin: Directions for future research. Automation in Construction, 114, 103179. | Implementing a semantic Construction Digital Twin: Directions for future research. | Introducing a standardized semantic representation of building components and systems using the Digital Twin conveys. Digital Twin is characterized by socio-technical and process-oriented characterization of the complex artefacts. | The review discusses the multi-faceted applications of BIM during the construction stage and highlights limits and requirements, paving the way to the concept of a Construction Digital Twin. | The study adopted the Digital Twin paradigm in the construction industry sector. Due to this technology, the concept of BIM gained sufficient recognition and momentum to enable a shift from a static, closed information environment to a dynamic. | |

| [30] BIM integrated smart monitoring technique for building fire prevention and disaster relief. Automation in Construction, 84, 14–30. | To integrate smart monitoring technique for building fire prevention and disaster relief BIM. | BIM was used to construct a BIM-based Intelligent Fire Prevention and Disaster Relief System. The methodology uses personal localization, on evacuation/rescue route optimization with Bluetooth-based technology, and on a mobile guidance device to create an intelligent and two-way fire disaster prevention system. | The results of applying the BIM-based system demonstrate that it may effectively provide 3D visualization to support the assessment and planning of fire safety. | The study contributes with providing early detection and alarm responses that is used for efficient evacuation and to facilitate fire rescue and control efforts in order to increase overall building safety and disaster-response capabilities. | |

| [50] Building Information Modeling (BIM) for transportation infrastructure–Literature review, applications, challenges, and recommendations. Automation in Construction, 94, 257–281. | Using BIM for improving the transportation infrastructure. | Develop more efficient and cost-effective techniques necessary to repair, advance, and expand the transportation infrastructure. | The results show that the use of BIM for transportation infrastructure has been increasing. More specifically, the research has mainly been focusing on roads, highways, and bridges. | There is a major need for a standard neutral exchange format and schema to promote interoperability. In addition, the continuing collaboration between academia and industry is required to mitigate most challenges and to realize the full potential of BIM for transportation infrastructure. | |

| [117] A framework for integrating BIM and IoT through open standards. Automation in Construction, 95, 35–45. | To create diverse fields including BIM, information system, Automation Systems, and IoT devices for the end users. | The methodology is to integrate the data with IoT sensors and web-based system called Otaniemi3D to integrate BIM and IoT devices through open messaging standards open message interface (O-MI) ad open data format (O-DF) and IFC models. | The paper describes the design criteria, the system architecture, the workflow, and a proof of concept with potential use cases that integrate IoT with the built environment. | The end users and other research groups can benefit from such platforms by either consuming the data in their daily life or using the data for more advance research. | |

| [9] Design and implementation of a novel service management framework for IoT devices in cloud. Journal of Systems and Software, 119, 149–161. | Adopting smart objects to transmit data to the cloud for processing and storage through IoT. | Combining the cloud computing environment with IoT to reduce the transmission and processing cost in the cloud and to provide better services for processing and storing the real time data generated from those IoT devices. | The proposed cloud framework combines IoT and cloud environment to provide services to both IoT and non-IoT users. | A novel framework is designed for the cloud to manage the real time IoT data and scientific non-IoT data. The other part of the framework is cloud, where data storage and process are carried out depending on the user requirement. | |

| [55] Automatic reconstruction of 3D building models from scanned 2D floor plans. Automation in Construction, 63, 48–56. | To significantly improve the systematic use of Information and Communication Technologies (ICT) tools and BIM. | The present article introduces a research work aiming at the development of methods for the generation of 3D building models from 2D plans. | A prototype can extract information from 2D plans and to generate IFC to include the main components of the building: walls, openings, and spaces. | Results are very promising and show that such solutions could be key components of future digital toolkits for renovation design. | |

| [109] Building performance optimization: a hybrid architecture for the integration of contextual information and time-series data. Automation in Construction, 70, 51–61. | To build sematic data for better feasibility of creating adapters between many different software tools. | Presenting a new solution to the semantic data by a hybrid architecture that links data which is retained in its original format. The architecture links existing and efficient relational databases storing time-series data and semantically described building contextual data. | The main contribution of this work is an original RDF syntax structure and ontology to represent existing database schema information, and a new mechanism that automatically prepares data streams for processing by rule-based performance definitions. | The hybrid architecture avoids the duplication of time-series data and overcomes some of the differences found in database schemas and database platforms. | |

| [144] An IoT-based autonomous system for workers’ safety in construction sites with real-time alarming, monitoring, and positioning strategies. Automation in Construction, 88, 73–86. | To protect construction workers and prevent accidents in such sites. | The design of the wearable device includes a set of components which are a radio transceiver (transmitter/receiver), a wake-up sensor, an alarm actuator, and a General Packet Radio Service (GPRS) module. | The heterogeneous components of this architecture are seamlessly integrated into a middleware backend online server. The wearable device has a power saving scheme with a current consumption as low as 0.5 μA at 3 V. | Presenting an implementation of wireless nodes that are powered by light energy using photovoltaic cells. These nodes adopt energy management and storage schemes for continuous operation for indoor and outdoor environments. | |

| [119] Top 10 technologies for indoor positioning on construction sites. Automation in Construction, 118, 103309. | Demonstrating indoor positioning enables five significant applications that considerably enhance work efficiency and safety on construction sites | Indoor positioning systems can be viewed as a combination of (1) creating corresponding algorithms, (2) indoor positioning technologies, and (3) indoor positioning hardware equipment. | Full analysis for challenges in applying six indoor positioning systems on construction sites. The system was to include technologies and principles. | A promising trends of indoor positioning development for indoor positioning hybridization was created using game theory positioning, and integration with BIM model. | |

| [37] Metadata Models and Methods for Smart Buildings (Doctoral dissertation, UC San Diego). | To use an effective sensing data and Heating, ventilation, and air conditioning (HVAC), security, lighting and sensing subsystems. | We envision building systems to exchange data across subsystems as well as across various building services in a programming framework. Such information exchange is mediated by timely sensor information. | A programming framework comprised of machine learning algorithms was developed relying on a standard information model for unified and secure application deployment | Demonstrating new devices such as thermostat called Genie, an energy dashboard, and a metadata models for building portable applications for smart buildings in this dissertation, we continue to pursue building a community of system builders for the smart building environments. | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Altohami, A.B.A.; Haron, N.A.; Ales@Alias, A.H.; Law, T.H. Investigating Approaches of Integrating BIM, IoT, and Facility Management for Renovating Existing Buildings: A Review. Sustainability 2021, 13, 3930. https://doi.org/10.3390/su13073930

Altohami ABA, Haron NA, Ales@Alias AH, Law TH. Investigating Approaches of Integrating BIM, IoT, and Facility Management for Renovating Existing Buildings: A Review. Sustainability. 2021; 13(7):3930. https://doi.org/10.3390/su13073930

Chicago/Turabian StyleAltohami, Abubaker Basheer Abdalwhab, Nuzul Azam Haron, Aidi Hizami Ales@Alias, and Teik Hua Law. 2021. "Investigating Approaches of Integrating BIM, IoT, and Facility Management for Renovating Existing Buildings: A Review" Sustainability 13, no. 7: 3930. https://doi.org/10.3390/su13073930