Real-Time Monitoring of a Botulinum Neurotoxin Using All-Carbon Nanotube-Based Field-Effect Transistor Devices

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Protein Samples

2.2. Preparation of Sensor Cover with a Microfluidic Channel

2.3. Fabrication of the All-CNT-Based FET Device

2.4. CNT Surface Modification

2.5. Electrical Measurement

2.6. Characterization of CNT Surface

3. Results and Discussion

3.1. Characteristics of the All-CNT-Based FET Device

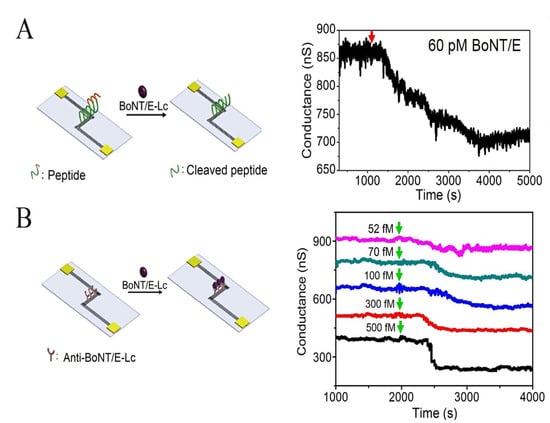

3.2. Real-Time Monitoring of the Interaction between Specific Peptides and BoNT

3.3. Observation of Specific Recognition between BoNT/E-Lc and Anti-BoNT/E-Lc

3.4. Surface Analysis of Carbon Nanotubes Using X-Ray Photoelectron Spectroscopy (XPS)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Patents

References

- Sakaguchi, G. Clostridium botulinum toxins. Pharmacol. Ther. 1983, 19, 165–194. [Google Scholar] [CrossRef]

- Montecucco, C.; Schiavo, G. Tetanus and botulism neurotoxins: A new group of zinc proteases. Trends Biochem. Sci. 1993, 18, 324–327. [Google Scholar] [CrossRef]

- Gill, D.M. Bacterial toxins: A table of lethal amounts. Microbiol. Rev. 1982, 46, 86–94. [Google Scholar] [PubMed]

- Schantz, E.J.; Johnson, E.A. Properties and use of botulinum toxin and other microbial neurotoxins in medicine. Microbiol. Rev. 1992, 56, 80–99. [Google Scholar] [PubMed]

- Arnon, S.S.; Schechter, R.; Inglesby, T.V.; Henderson, D.A.; Bartlett, J.G.; Ascher, M.S.; Eitzen, E.; Fine, A.D.; Hauer, J.; Layton, M.; et al. Working Group on Civilian Biodefense, Botulinum toxin as a biological weapon: Medical and public health management. JAMA 2001, 285, 1059–2081. [Google Scholar] [CrossRef] [PubMed]

- Martin, C.O.; Adams, H.P. Neurological aspects of biological and chemical terrorism: A review for neurologists. Arch. Neurol. 2003, 60, 21–25. [Google Scholar] [CrossRef] [PubMed]

- Shone, C.; Wilton-Smith, P.; Appleton, N.; Hambleton, P.; Modi, N.; Gatley, S.; Melling, J. Monoclonal antibody-based immunoassay for type A Clostridium botulinum toxin is comparable to the mouse bioassay. Appl. Environ. Microbiol. 1985, 50, 63–67. [Google Scholar]

- Kalb, S.R.; Boyer, A.E.; Barr, J.R. Mass spectrometric detection of bacterial protein toxins and their enzymatic activity. Toxins 2015, 7, 3497–3511. [Google Scholar] [CrossRef]

- Szilagyi, M.; Rivera, V.R.; Neal, D.; Merrill, G.A.; Poli, M.A. Development of sensitive colorimetric capture elisas for Clostridium botulinum neurotoxin serotypes A and B. Toxicon 2000, 38, 381–389. [Google Scholar] [CrossRef]

- Sharma, S.K.; Ferreira, J.L.; Eblen, B.S.; Whiting, R.C. Detection of type A, B, E, and F Clostridium botulinum neurotoxins in foods by using an amplified enzyme-linked immunosorbent assay with digoxigenin-labeled antibodies. Appl. Environ. Microbiol. 2006, 72, 1231–1238. [Google Scholar] [CrossRef]

- Singh, A.; Datta, S.; Sachdeva, A.; Maslanka, S.; Dykes, J.; Skinner, G.; Burr, D.; Whiting, R.C.; Sharma, S.K. Evaluation of an enzyme-linked immunosorbent assay (ELISA) kit for the detection of botulinum neurotoxins A, B, E, and F in selected food matrices. Health. Secur. 2015, 13, 37–44. [Google Scholar] [CrossRef] [PubMed]

- Lévêgue, C.; Ferracci, G.; Maulet, Y.; Grand-Masson, C.; Blanchard, M.P.; Seagar, M.; El Far, O. A substrate sensor chip to assay the enzymatic activity of Botulinum neurotoxin A. Biosens. Bioelectron. 2013, 49, 276–281. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gessler, F.; Pagel-Wieder, S.; Avonder, M.A.; Böhnel, H. Evaluation of lateral flow assays for the detection of botulinum neurotoxin type A and their application in laboratory diagnosis of botulism. Diagn. Microbiol. Infect. Dis. 2007, 57, 243–249. [Google Scholar] [CrossRef] [PubMed]

- Chiao, D.J.; Wey, J.J.; Shyu, R.H.; Tang, S.S. Monoclonal antibody-based lateral flow assay for detection of botulinum neurotoxin type A. Hybridoma (Larchmt) 2008, 27, 31–35. [Google Scholar] [CrossRef] [PubMed]

- Babrak, L.; Lin, A.; Stanker, L.H.; McGarvey, J.; Hnasko, R. Rapid microfluidic assay for the detection of botulinum neurotoxin in animal sera. Toxins 2016, 8, E13. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Gao, S.; Kang, L.; Ji, B.; Xin, W.; Kang, J.; Li, P.; Gao, J.; Wang, H.; Wang, J.; et al. An Ultrasensitive Gold Nanoparticle-based Lateral Flow Test for the Detection of Active Botulinum Neurotoxin Type A. Nanoscale Res. Lett. 2017, 12, 227. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mizanur, R.M.; Stafford, R.G.; Ahmed, S.A. Cleavage of SNAP25 and its shorter versions by the protease domain of serotype A botulinum neurotoxin. PLoS ONE 2014, 9, e95188. [Google Scholar] [CrossRef]

- Dong, M.; Tepp, W.H.; Johnson, E.A.; Chapman, E.R. Using fluorescent sensors to detect botulinum neurotoxin activity in vitro and in living cells. Proc. Natl. Acad. Sci. USA 2004, 101, 14701–14706. [Google Scholar] [CrossRef] [Green Version]

- Zheng, G.; Patolsky, F.; Cui, Y.; Wang, W.U.; Lieber, C.M. Multiplexed electrical detection of cancer markers with nanowire sensor arrays. Nat. Biotechol. 2005, 23, 1294–1301. [Google Scholar] [CrossRef]

- Maehashi, K.; Katsura, T.; Kerman, K.; Takamura, Y.; Matsumoto, K.; Tamiya, E. Label-free protein biosensor based on aptamer-modified carbon nanotube field-effect transistors. Anal. Chem. 2007, 79, 782–787. [Google Scholar] [CrossRef]

- Wang, D.; Krilich, J.; Baudys, J.; Barr, J.R.; Kalb, S.R. Optimization of peptide substrates for botulinum neurotoxin E improves detection sensitivity in the Endopep–MS assay. Anal. Biochem. 2015, 468, 15–21. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Montana, V.; Grubišić, V., Jr.; Stout, R.F.; Parpura, V.; Gu, L.Q. Nanopore sensing of botulinum toxin type B by discriminating an enzymatically cleaved peptide from a synaptic protein synaptobrevin 2 derivative. ACS Appl. Mater. Interfaces 2015, 7, 184–192. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Chen, H.; Niu, W.; Fam, D.W.H.; Palaniappan, A.; Larisika, M.; Faulkner, S.H.; Nowak, C.; Nimmo, M.A.; Liedberg, B.; et al. Highly manufacturable graphene oxide biosensor for sensitive Interleukin-6 detection. RSC Adv. 2015, 5, 39245–39251. [Google Scholar] [CrossRef]

- Chen, H.; Huang, J.; Palaniappan, A.; Wang, Y.; Liedberg, B.; Platt, M.; Tok, A.I.Y. A review on electronic bio-sensing approaches based on non-antibody recognition elements. Analyst 2016, 141, 2335–2346. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, C.; Curreli, M.; Lin, H.; Lei, B.; Ishikawa, F.N.; Datar, R.; Cote, R.J.; Thompson, M.E.; Zhou, C. Complementary detection of prostate-specific antigen using In2O3 nanowires and carbon nanotubes. J. Am. Chem. Soc. 2005, 127, 12484–12485. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Shin, Y.M.; Song, J.J.; Yang, H. Facile electrochemical detection of botulinum neurotoxin type E using a two-step proteolytic cleavage. Biosens. Bioelectron. 2015, 72, 211–217. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Tang, Y.; Zhang, L.; Wu, J. Label-free study of the function of ion channel protein on a microfluidic optical sensor integrated with artificial cell membrane. Lab Chip. 2014, 14, 333–341. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Li, Q.; Tu, Y.; Li, Y.; Coulter, J.Y.; Zheng, L.; Zhao, Y.; Jia, Q.; Peterson, D.E.; Zhu, Y. Strong carbon-nanotube fibers spun from long carbon-nanotube arrays. Small 2007, 3, 244–248. [Google Scholar] [CrossRef]

- Lee, I.H.; Han, G.H.; Chae, S.J.; Bae, J.J.; Kim, E.S.; Kim, S.M.; Kim, T.H.; Jeong, H.K.; Lee, Y.H. Criteria for producing yarns from vertically aligned carbon nanotubes. Nano 2010, 5, 31–38. [Google Scholar] [CrossRef]

- Tasis, D.; Tagmatarchis, N.; Bianco, A.; Prato, M. Chemistry of carbon nanotubes. Chem. Rev. 2006, 106, 1105–1136. [Google Scholar] [CrossRef]

- Collins, P.G.; Arnold, M.S.; Avouris, P. Engineering carbon nanotubes and nanotube circuits using electrical breakdown. Science 2001, 292, 706–709. [Google Scholar] [CrossRef] [PubMed]

- Nourbakhsh, A.; Cantoro, M.; Vosch, T.; Pourtois, G.; Clemente, F.; van der Veen, M.H.; Hofkens, J.; Heyns, M.M.; De Gendt, S.; Sels, B.F. Bandgap opening in oxygen plasma-treated graphene. Nanotechnology 2010, 21, 435203. [Google Scholar] [CrossRef] [PubMed]

- Ham, S.W.; Hong, H.P.; Kim, J.H.; Min, S.J.; Min, N.K. Effect of Oxygen Plasma Treatment on Carbon Nanotube-Based Sensors. J. Nanosci. Nanotechnol. 2014, 14, 8476–8481. [Google Scholar] [CrossRef] [PubMed]

- Kocabas, D.; Hur, S.H.; Gaur, A.; Meitl, M.A.; Shim, M.; Rogers, J.A. Guided growth of large-scale, horizontally aligned arrays of single-walled carbon nanotubes and their use in thin-film transistors. Small 2005, 11, 1110–1116. [Google Scholar] [CrossRef] [PubMed]

- Vaidyanathan, V.V.; Yoshino, K.; Jahnz, M.; Dörries, C.; Bade, S.; Nauenburg, S.; Niemann, H.; Binz, T. Proteolysis of SNAP-25 isoforms by botulinum neurotoxin types A, C, and E: Domains and amino acid residues controlling the formation of enzyme-substrate complexes and cleavage. J. Neurochem. 1999, 72, 327–337. [Google Scholar] [CrossRef] [PubMed]

- McArthur, S.L.; Mishra, G.; Easton, C.D. Surface Analysis and Techniques in Biology. In Applications of XPS in Biology and Biointerface Analysis, 1st ed.; Sementkowski, V., Ed.; Springer: Cham, Switzerland, 2014; pp. 9–36. ISBN 978-3-319-01359-6. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, N.H.; Nahm, S.-H.; Choi, I.S. Real-Time Monitoring of a Botulinum Neurotoxin Using All-Carbon Nanotube-Based Field-Effect Transistor Devices. Sensors 2018, 18, 4235. https://doi.org/10.3390/s18124235

Lee NH, Nahm S-H, Choi IS. Real-Time Monitoring of a Botulinum Neurotoxin Using All-Carbon Nanotube-Based Field-Effect Transistor Devices. Sensors. 2018; 18(12):4235. https://doi.org/10.3390/s18124235

Chicago/Turabian StyleLee, Nam Hee, Seung-Hoon Nahm, and Insung S. Choi. 2018. "Real-Time Monitoring of a Botulinum Neurotoxin Using All-Carbon Nanotube-Based Field-Effect Transistor Devices" Sensors 18, no. 12: 4235. https://doi.org/10.3390/s18124235