InSAR- and PIM-Based Inclined Goaf Determination for Illegal Mining Detection

Abstract

:1. Introduction

2. Methodology

2.1. Principle of the PIM

2.2. Relationship between Subsidence Curve and Horizontal Working Face Position

2.3. Deformation Propagation Characteristics of an Inclined Coal Seam

2.4. Inversion Method of Mining Goafs

2.4.1. Determination of the Strike Boundary and Average Mining Depth

2.4.2. Determination of the Inclination

2.4.3. Determination of the Dip Boundary

3. Simulation Experiment

3.1. Simulation Experiment

3.2. Simulation Results and Analysis

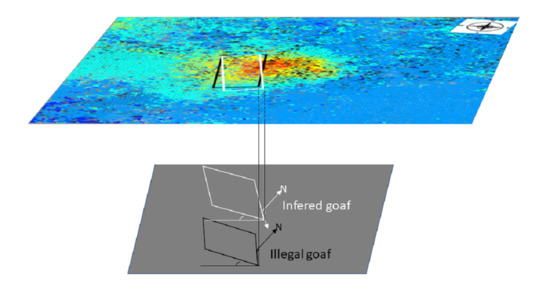

4. Project Example

4.1. Study Area and Data Sets

4.2. InSAR Processing

4.3. Results

5. Discussion

5.1. Leveling Data Verification

5.2. The Relationship between Mining Depth in the Dip Direction and the Main Influence Radius

5.3. Influence of Insufficient Mining

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Available online: https://www.worldcoal.org/coal/coal-mining (accessed on 25 November 2020).

- Miao, X.X.; Qian, M.G. Research on green mining of coal resources in China: Current status and future prospects. J. Min. Saf. Eng. 2009, 26, 1–14. [Google Scholar]

- Han, R.L.; Nan, S.Q.; Li, F.P.; Guo, X.Z.; Su, M.; Wan, X.J. Application of Micro-seismic Monitoring on Fighting Against Illegal Mining. J. Hebei Polytech. Univ. (Nat. Sci. Ed.) 2011, 4. [Google Scholar]

- Engelbrecht, J.; Inggs, M. Differential interferometry techniques on L-band data employed for the monitoring of surface subsidence due to mining. S. Afr. J. Geomat. 2013, 2, 82–93. [Google Scholar]

- Herrera, G.; Tomás, R.; López-Sánchez, J.M.; Delgado, J.; Mallorqui, J.J.; Duque, S.; Mulas, J. Advanced DInSAR analysis on mining areas: La Union case study (Murcia, SE Spain). Eng. Geol. 2007, 90, 148–159. [Google Scholar] [CrossRef] [Green Version]

- Ishwar, S.G.; Kumar, D. Application of DInSAR in mine surface subsidence monitoring and prediction. Curr. Sci. 2017, 112, 46–51. [Google Scholar] [CrossRef]

- Przyłucka, M.; Herrera, G.; Graniczny, M.; Colombo, D.; Béjar-Pizarro, M. Combination of conventional and advanced DInSAR to monitor very fast mining subsidence with TerraSAR-X data: Bytom City (Poland). Remote Sens. 2015, 7, 5300–5328. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Li, Z.; Zhu, J.; Yi, H.; Feng, G.; Hu, J.; Wu, L.; Preusse, A.; Wang, Y.; Papst, M. Locating and defining underground goaf caused by coal mining from space-borne SAR interferometry. ISPRS J. Photogramm. Remote. Sens. 2018, 135, 112–126. [Google Scholar] [CrossRef]

- Du, S.; Wang, Y.; Zheng, M.; Zhou, D.; Xia, Y. Goaf Locating Based on InSAR and Probability Integration Method. Remote Sens. 2019, 11, 812. [Google Scholar] [CrossRef] [Green Version]

- Litwiniszyn, J. The theories and model research of movements of ground masses. Proceedings of the European congress on ground movement. Univ. Leeds 1957, 202, 209. [Google Scholar]

- Deng, K.Z.; Tan, Z.X.; Jiang, Y. Subject of Deformation Monitoring and Subsidence Engineering; China University of Mining and Technology Press: Xuzhou, China, 2015. [Google Scholar]

- Fan, H.; Lu, L.; Yao, Y. Method combining probability integration model and a small baseline subset for time series monitoring of mining subsidence. Remote Sens. 2018, 10, 1444. [Google Scholar] [CrossRef] [Green Version]

- Ministry of Coal Industry. Regulations for Coal Pillar Retention and Coal Mining in Buildings, Water Bodies, Railways and Main Shafts; Coal Industry Press: Beijing, China, 1986.

- Abbo, A.J.; Sloan, S.W. A smooth hyperbolic approximation to the Mohr-Coulomb yield criterion. Comput. Struct. 1995, 54, 427–441. [Google Scholar] [CrossRef]

- Chen, Q. Analysis of Water Quality Test Results of Ordovician Limestone Water in Fengfeng Mining Area. Occup. Health 2009, 25, 1974. [Google Scholar]

- Nie, C. Research on Comprehensive Planning and Utilization of Water Resources in Fengfeng Mining Area of Handan City; Hebei University of Engineering: Handan, China, 2010. [Google Scholar]

- Du, L.; Zhu, W.; Tian, X. Climatic characteristics analysis of different grades of precipitation days in Handan area. J. Meteorol. Environ. 2017, 33, 102–107. [Google Scholar]

- Liu, Y.; Hu, B.; Zhang, F. Carboniferous-Permian sandstone microstructure in Tonger Minefield, Fengfeng Mining Area, Hebei Province Analysis of structural characteristics. Mod. Geol. 2003, 17, 75–79. [Google Scholar]

- Cao, D.; Zhan, W.; Zhang, J. New structural features of Handan-Fengfeng mining area and its significance for coal resource development. J. China Coal Soc. 2007, 32, 141–145. [Google Scholar]

- Hebei University of Engineering. Jiulong Mine Geology Report; Jizhong Energy Fengfeng Group: Handan, China.

- Lai, S.; Dong, Y. Fengfeng Group’s methods and approaches to increase the recovery rate of coal resources. Coal Mine Saf. 2014, 45, 191–193. [Google Scholar]

- Mora, O.; Mallorqui, J.J.; Broquetas, A. Linear and nonlinear terrain deformation maps from a reduced set of interferometric SAR images. IEEE Trans. Geosci. Remote Sens. 2003, 41, 2243–2253. [Google Scholar] [CrossRef]

- Blanco-Sanchez, P.; Mallorquí, J.J.; Duque, S.; Monells, D. The coherent pixels technique (CPT): An advanced DInSAR technique for nonlinear deformation monitoring. Pure Appl. Geophys. 2008, 165, 1167–1193. [Google Scholar] [CrossRef]

| Country | Coal Extraction (Mt) | Country | Coal Extraction (Mt) |

|---|---|---|---|

| PR China | 3550 | Russia | 420 |

| India | 771 | South Africa | 259 |

| USA | 685 | Germany | 169 |

| Indonesia | 549 | Poland | 122 |

| Australia | 483 | Kazakhstan | 114 |

| Strike Direction | Length | Width | Average Depth | Depth in Uphill Direction | Depth in Downhill Direction | Inclination Angle | |

|---|---|---|---|---|---|---|---|

| Calculated value | 305 m | 311 m | 228 m | 209 m | 247 m | ||

| Real value | 300 m | 350 m | 225 m | 200 m | 250 m | ||

| Relative error | 1.11% | 1.67% | 11.14% | 1.33% | 4.50% | 1.20% | 1.23% |

| Strike Direction | Length | Width | Average Depth | Depth in Uphill Direction | Depth in Downhill Direction | Inclination Angle | |

|---|---|---|---|---|---|---|---|

| Calculated value | 342 m | 138 m | 759 m | 761 m | 802 m | ||

| Real value | 319 m | 3165 m | 774 m | 733 m | 845 m | ||

| Relative error | 3.55% | 7.21% | 16.36% | 1.94% | 3.82% | 5.09% | 6.45% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, Y.; Wang, Y. InSAR- and PIM-Based Inclined Goaf Determination for Illegal Mining Detection. Remote Sens. 2020, 12, 3884. https://doi.org/10.3390/rs12233884

Xia Y, Wang Y. InSAR- and PIM-Based Inclined Goaf Determination for Illegal Mining Detection. Remote Sensing. 2020; 12(23):3884. https://doi.org/10.3390/rs12233884

Chicago/Turabian StyleXia, Yuanping, and Yunjia Wang. 2020. "InSAR- and PIM-Based Inclined Goaf Determination for Illegal Mining Detection" Remote Sensing 12, no. 23: 3884. https://doi.org/10.3390/rs12233884