Automated Inspection of Railway Tunnels’ Power Line Using LiDAR Point Clouds

Abstract

:1. Introduction

2. Literature Review

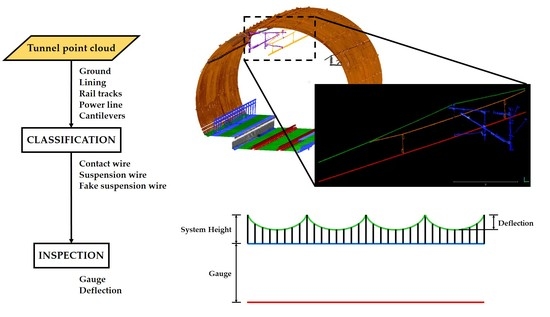

3. Methodology

3.1. Classification of Points

3.1.1. Contact wire detection

3.1.2. Suspension wire detection

3.2. Gauge and Deflection

4. Equipment Setup

4.1. Geo-Referencing and Sensor Fusion

4.2. Performance

- Laser range error: measuring the distance to an object. It is different for every scanner and can be corrected by recalibrating them (by the manufacturer or specialist in the field).

- Range noise: deviation of single readings from the real value within a sample of measures. It is conditioned by the distance to the object to be scanned and the reflectivity of the object’s material.

- Mechanical error: the difference between the measured and actual horizontal and vertical angles (angular error). It is caused by the mechanical devices forming the laser scanner (mirrors and servos).

5. Results

5.1. Case Study

5.2. Classification Results

5.3. Inspection Results

5.4. Global Discussion

5.5. Error Analysis

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- FaroArm®|FARO SPAIN, S.L.U. Available online: https://www.faro.com/es-es/productos/3d-manufacturing/faroarm/ (accessed on 12 August 2019).

- Adif. Ministerio de Fomento, Gobierno de España. Available online: http://www.adif.es/ (accessed on 6 February 2019).

- Gil Calvo, M.A.; Jiménez Cano, A.; Estévez Cárdenas, F. Línea Aérea de Contacto unificado para Catenarias CA-160 y CA-220, 2nd ed.; ADIF: Madrid, Spain, 2008. [Google Scholar]

- Arastounia, M. An Enhanced Algorithm for Concurrent Recognition of Rail Tracks and Power Cables from Terrestrial and Airborne LiDAR Point Clouds. Infrastructures 2017, 2, 8. [Google Scholar] [CrossRef]

- Soni, A.; Robson, S.; Gleeson, B. Extracting Rail Track Geometry from Static Terrestrial Laser Scans for Monitoring Purposes. ISPRS—Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2014, XL–5, 553–557. [Google Scholar] [CrossRef]

- Collin, B.; Carreaud, P.; Lançon, H. High Efficiency Techniques for the Assessment of Railways Infrastructures and Buildings. In Proceedings of the Transportation Research Procedia, Shanghai, China, 10–15 July 2016; pp. 1865–1874. [Google Scholar]

- Soilán, M.; Sánchez-Rodríguez, A.; del Río-Barral, P.; Perez-Collazo, C.; Arias, P.; Riveiro, B. Review of Laser Scanning Technologies and Their Applications for Road and Railway Infrastructure Monitoring. Infrastructures 2019, 4, 58. [Google Scholar] [CrossRef]

- Che, E.; Jung, J.; Olsen, M.J. Object recognition, segmentation, and classification of mobile laser scanning point clouds: A state of the art review. Sensors 2019, 19, 810. [Google Scholar] [CrossRef] [PubMed]

- Leslar, M.; Perry, G.; McNease, K. Using mobile lidar to survey a railway line for asset inventory. In Proceedings of the American Society for Photogrammetry and Remote Sensing Annual Conference 2010: Opportunities for Emerging Geospatial Technologies, San Diego, CA, USA, 26–30 April 2010; pp. 526–533. [Google Scholar]

- Arastounia, M. Automatic Classification of LiDAR Point Clouds in A Railway Environment; University of Twente Faculty of Geo-Information and Earth Observation: Enschede, The Netherlands, 2012. [Google Scholar]

- Arastounia, M. Automated Recognition of Railroad Infrastructure in Rural Areas from LIDAR Data. Remote Sens. 2015, 7, 14916–14938. [Google Scholar] [CrossRef] [Green Version]

- Arastounia, M.; Elberink, S.O. Application of Template Matching for Improving Classification of Urban Railroad Point Clouds. Sensors 2016, 16, 2112. [Google Scholar] [CrossRef] [PubMed]

- Pastucha, E. Catenary System Detection, Localization and Classification Using Mobile Scanning Data. Remote Sens. 2016, 8, 801. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, C.; Yang, Z.; Chen, Y.; Li, J. Automatic railway power line extraction using mobile laser scanning data. In Proceedings of the International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences—ISPRS Archives, Prague, Czech, 12–19 July 2016; pp. 615–619. [Google Scholar]

- Guo, B.; Li, Q.; Huang, X.; Wang, C. An Improved Method for Power-Line Reconstruction from Point Cloud Data. Remote Sens. 2016, 8, 36. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Q.; Liu, L.; Li, K. A Hierarchical unsupervised method for power line classification from airborne LiDAR data. Int. J. Digit. Earth 2018, 1–17. [Google Scholar] [CrossRef]

- Blug, A.; Baulig, C.; Wolfelschneider, H.; Hofler, H. Fast fiber coupled clearance profile scanner using real time 3D data processing with automatic rail detection. In Proceedings of the IEEE Intelligent Vehicles Symposium, Parma, Italy, 14–17 June 2004; pp. 658–663. [Google Scholar]

- Mikrut, S.; Kohut, P.; Pyka, K.; Tokarczyk, R.; Barszcz, T.; Uhl, T. Mobile Laser Scanning Systems for Measuring the Clearance Gauge of Railways: State of Play, Testing and Outlook. Sensors 2016, 16, 683. [Google Scholar] [CrossRef] [PubMed]

- Luo, C.; Jwa, Y.; Sohn, G. Context based multiple railway object recognition from mobile laser scanning data. Int. Geosci. Remote Sens. Symp. 2014, 3602–3605. [Google Scholar]

- Sánchez-Rodríguez, A.; Riveiro, B.; Soilán, M.; González-deSantos, L.M. Automated detection and decomposition of railway tunnels from Mobile Laser Scanning Datasets. Autom. Constr. 2018, 96, 171–179. [Google Scholar] [CrossRef]

- Qi, C.R.; Su, H.; Mo, K.; Guibas, L.J. PointNet: Deep Learning on Point Sets for 3D Classification and Segmentation. IEEE Conf. Comput. Vis. Pattern Recognit. 2016, 601–610. [Google Scholar]

- Qi, C.R.; Yi, L.; Su, H.; Guibas, L.J. PointNet++: Deep Hierarchical Feature Learning on Point Sets in a Metric Space. In Proceedings of the Neural Information Processing Systems, Long Beach, CA, USA, 4–9 December 2017. [Google Scholar]

- Tatarchenko, M.; Dosovitskiy, A.; Brox, T. Octree Generating Networks: Efficient Convolutional Architectures for High-Resolution 3D Outputs. In Proceedings of the IEEE International Conference on Computer Vision, Venice, Italy, 22–29 October 2017. [Google Scholar]

- Su, H.; Jampani, V.; Sun, D.; Maji, S.; Kalogerakis, E.; Yang, M.H.; Kautz, J. SPLATNet: Sparse Lattice Networks for Point Cloud Processing. In Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–22 June 2018. [Google Scholar]

- Balado, J.; Arias, P.; Díaz-Vilariño, L.; González-Desantos, L.M. Automatic CORINE land cover classification from airborne LIDAR data. Procedia Comput. Sci. 2018, 126, 186–194. [Google Scholar] [CrossRef]

- Balado, J.; Martínez-sánchez, J.; Arias, P.; Novo, A. Road Environment Semantic Segmentation with Deep Learning from MLS Point Cloud Data. Sensors 2019, 19, 3466. [Google Scholar] [CrossRef] [PubMed]

- Luo, Z.; Li, J.; Xiao, Z.; Mou, Z.G.; Cai, X.; Wang, C. Learning high-level features by fusing multi-view representation of MLS point clouds for 3D object recognition in road environments. ISPRS J. Photogramm. Remote Sens. 2019, 150, 44–58. [Google Scholar] [CrossRef]

- Kumar, B.; Pandey, G.; Lohani, B.; Misra, S.C. A multi-faceted CNN architecture for automatic classification of mobile LiDAR data and an algorithm to reproduce point cloud samples for enhanced training. ISPRS J. Photogramm. Remote Sens. 2019, 147, 80–89. [Google Scholar] [CrossRef]

- Hemández Puertas, J. Cálculo de Esfuerzos y Desplazamientos sobre Pórticos CA-220 con Matlab; Universidad Pontificia Comillas: Madrid, Spain, 2016. [Google Scholar]

- Soilán, M.; Riveiro, B.; Martínez-Sánchez, J.; Arias, P. Traffic sign detection in MLS acquired point clouds for geometric and image-based semantic inventory. ISPRS J. Photogramm. Remote Sens. 2016, 114, 92–101. [Google Scholar] [CrossRef]

- MathWorks-Makers of MATLAB and Simulink. Available online: https://es.mathworks.com/ (accessed on 17 Januarey 2018).

- Teledyne Optech © Teledyne Optech. Available online: http://www.teledyneoptech.com/en/home/ (accessed on 11 June 2019).

- Puente, I.; González-Jorge, H.; Riveiro, B.; Arias, P. Accuracy verification of the Lynx Mobile Mapper system. Opt. Laser Technol. 2013, 45, 578–586. [Google Scholar] [CrossRef]

- Díaz, O. Understanding Accuracy in Laser Scanners|SmartGeoMetrics. Available online: http://www.smartgeometrics.com/2013/08/28/understanding-accuracy-in-laser-scanners-2/ (accessed on 30 January 2019).

- RIEGL—RIEGL Laser Measurement Systems. Available online: http://www.riegl.com/ (accessed on 1 November 2019).

- Filgueira, A.; González-Jorge, H.; Lagüela, S.; Díaz-Vilariño, L.; Arias, P. Quantifying the influence of rain in LiDAR performance. Meas. J. Int. Meas. Confed. 2017, 95, 143–148. [Google Scholar] [CrossRef]

| Characteristic | Wire Type | Catenary Model | |

|---|---|---|---|

| CA-160 | CA-220 | ||

| Section | Suspension | Cu 150 mm2 | Cu 185 mm2 |

| Contact | 2× Cu 107 mm2 | 2× Cu-Ag 0.1–150 mm2 | |

| Nominal height | Contact | 5.30 m | 5.30 m |

| System | 1.4 m | 1.4 m | |

| Minimum height | Contact | 4.60 m | 4.90 m |

| Maximum Span | Suspension | 60 m | 60 m |

| Maximum deflection 1 | Suspension | 0.853 m | 0.853 m |

| Manufacturer | LiDAR Model | Maximum Range | Range Precision | PRF (Pulse Repetition Frequency) | Scan Frequency | Field of View |

|---|---|---|---|---|---|---|

| Teledyne Optech | Lynx M1 | 200 m | 8 mm | 75–500 kHz | 80–200 Hz | 360° |

| Dataset | No. of Sections (20 m Long) | No. of Points | Longitudinal Length (m) |

|---|---|---|---|

| Tunnel A | 42 | 332,646,619 | 877 |

| Tunnel B | 54 | 168,437,020 | 1151 |

| Tunnel C | 4 | 45,788,061 | 51.3 |

| Tunnel | Dataset Number | No. of Points (Total) | No. of Points (Power Line 1) |

|---|---|---|---|

| A | 10 | 7,241,901 | 36,516 |

| B | 11 | 2,955,005 | 12,146 |

| C | 4 | 19,687,427 | 61,075 |

| Tunnel | Element | TP | FP | FN | Precision | Recall | F-score |

|---|---|---|---|---|---|---|---|

| A | Contact wire | 2011 | 818 | 761 | 0.9609 | 0.9636 | 0.9622 |

| Suspension wire | 7269 | 411 | 379 | 0.9465 | 0.9504 | 0.9485 | |

| B | Contact wire | 6578 | 244 | 305 | 0.9642 | 0.9557 | 0.9599 |

| Suspension wire | 3053 | 220 | 193 | 0.9328 | 0.9405 | 0.9366 | |

| C | Contact wire | 26371 | 1344 | 1028 | 0.9515 | 0.9625 | 0.9570 |

| Suspension wire | 15900 | 870 | 1322 | 0.9481 | 0.9232 | 0.9355 |

| Tunnel | Dataset Number | No. of Points (Suspension Wire) | Deflection (m) |

|---|---|---|---|

| A | 8-10 | 57,750 | 0.59 |

| B | 8-11 | 26,482 | 0.67 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez-Rodríguez, A.; Soilán, M.; Cabaleiro, M.; Arias, P. Automated Inspection of Railway Tunnels’ Power Line Using LiDAR Point Clouds. Remote Sens. 2019, 11, 2567. https://doi.org/10.3390/rs11212567

Sánchez-Rodríguez A, Soilán M, Cabaleiro M, Arias P. Automated Inspection of Railway Tunnels’ Power Line Using LiDAR Point Clouds. Remote Sensing. 2019; 11(21):2567. https://doi.org/10.3390/rs11212567

Chicago/Turabian StyleSánchez-Rodríguez, Ana, Mario Soilán, Manuel Cabaleiro, and Pedro Arias. 2019. "Automated Inspection of Railway Tunnels’ Power Line Using LiDAR Point Clouds" Remote Sensing 11, no. 21: 2567. https://doi.org/10.3390/rs11212567